Peracetic Acid for Secondary Municipal Wastewater Disinfection

By Jacquelyn N. Wilson

Wastewater often contains microorganisms, transition metal ions, and other contaminants. While chlorine is the most common disinfectant used in the municipal wastewater industry, it has two drawbacks: its potential to form unwanted and toxic disinfection by-products such as trihalomethanes (THMs) and its effect of increasing the salinity of wastewater.

Peracetic acid (PAA) offers an effective and safe alternative. It is an oxidizing biocide that degrades relatively quickly into non-toxic by-products. Due to the absence of halogens such as chlorine or bromine, PAA has no risk of forming THMs.

Lexington Water Systems in Tennessee trialed 22% peracetic acid (PAA) called Peragreen® 22WW that was manufactured by Enviro Tech Chemical Services and supplied by Harcros Chemicals. The 1.2 million gallon per day (MGD) secondary wastewater treatment facility previously disinfected using chlorine. The incentive to change disinfectants was primarily driven by a reduction in chemical costs and to eliminate the need to quench residual chlorine before effluent discharge.

To conduct the trial, state regulatory approval for use of 22% PAA as a wastewater disinfectant was required. Two chronic toxicological studies were performed by Commonwealth Biomonitoring on Ceriodaphnia dubia and Pimephales promelas as a prerequisite for approval by the Tennessee Department of Environment & Conservation (TDEC).

Background testing was conducted to evaluate the efficacy of PAA against microorganisms in Lexington’s municipal wastewater. Decay curves for both PAA and hydrogen peroxide (H2O2) determined that PAA would persist through the wastewater system in order to deactivate pathogens at permitted levels.

Decay curves were rendered by producing a stock solution of PAA, which was then used to dose a wastewater sample obtained from the Lexington Water System. Concentration of PAA and H2O2 were monitored over time using the Palin DPD methodology. The results of the decay study indicated acceptable stability of both active ingredients in the wastewater sample. Based on these results, the Peragreen 22WW product demonstrated stability in the Lexington wastewater sample and therefore was likely to be economically viable and very effective as a disinfectant.

The Trial

Lexington Water Systems has an average flow of 1.2 MGD with a peak design flow of 3.3 MGD. The wastewater treatment works is an aerated conventional activated sludge earthen basin system. It is a modification of a dual-lagoon system. Wastewater flow travels through screening and then into the treatment system. During high flow periods, the old primary lagoon can be used as an equalization basin. After primary treatment, flow goes through two circular clarifiers. The flow then goes into a chlorine contact chamber with a maximum of three hours contact time. The Lexington wastewater NPDES permit dictates the monitoring of E. coli with a monthly geometric mean limit of 126 CFU/100 mL and daily maximum of 941 CFU/100 mL. During summer months, algal growth increases in the lagoons.

On March 3, 2016, the PAA wastewater trial began and ran through July 2016. Initial PAA feed rates were set at 1.0 mg/L, achieving deactivation of E. coli to as low as 1 CFU/100 mL. As the trial progressed, algal growth increased in the lagoons prior to contact chamber, which resulted in higher demand of PAA. Thus, PAA feed rates were adjusted to 1.2 mg/L with a maximum E. coli count of 35 CFU/100 mL during the initial startup of the trial. Average PAA feed rate throughout the trial was 1.27 mg/L with an average E. coli count of 24 CFU/100 mL.

The trial was setup to last six months. Residual PAA and H2O2 levels were to be measured every day during regular operation. E. coli counts were to be monitored according to permit requirements. Biomonitoring as well as a stream bioassessment were to be completed during this trial. Points of success for the trial were to maintain pathogen reduction below the NPDES permit limit and maintain a PAA residual throughout the contact chamber at maximum contact time and at increased levels of algal growth. Totes of Peragreen 22WW, 300 gallons each, were set up near the existing chlorine contact chamber where any possible spill would be contained in the immediate area and contact basin. Using the Enviro Tech Safe-T-Feed® System, PAA was drawn from the top of the totes using peristaltic pumps for chemical feed. Product was fed into the effluent flume at the start of the contact chamber.

Lexington Water Systems, Harcros Chemicals and Enviro Tech Chemical Services worked together throughout the trial to ensure its success. Lexington Water Systems designed, purchased and installed all safety and feed equipment. Enviro Tech Chemical Services and Harcros Chemicals were present for startup and supported Lexington Water Systems through the regulatory approval process.

Results

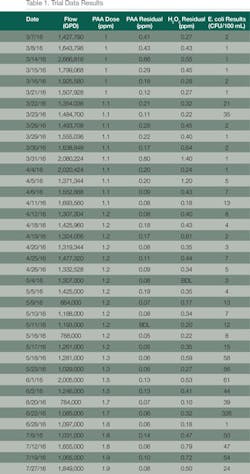

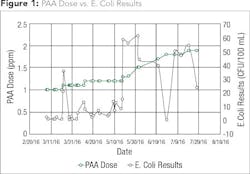

During the first two weeks of the trial, the PAA feed rate was 1.0 mg/L, achieving an average measured PAA residual of 0.35 mg/L and average measured E. coli count of 1.33 CFU/100 mL (see Table 1). The PAA feed rate was then increased to 1.1 mg/L during weeks three and four, resulting in the measured average residual of 0.24 mg/L and average E. coli count of 8.8 CFU/100 mL. The PAA feed rate was again increased in late April to 1.2 mg/L. Average PAA residual during this time period was 0.12 mg/L and average E. coli count was 5 CFU/100 mL. The PAA feed rate was gradually increased to a maximum feed rate of 1.9 mg/L near the end of the initial trial period in July 2016 to overcome the additional demand caused by increased algal growth. PAA dosage during this time was partially determined by the H2O2 residual levels in the outfall due to concerns over the amounts of H2O2 discharged into the receiving stream (see Fig. 1).

Maximum and minimum flow rates during the trial were 2.3 MGD and 0.5 MGD, respectively. The maximum E. coli count was 326 CFU/100 mL and overall average E. coli count was 24 CFU/100 mL. PAA feed rates averaged 1.27 mg/L.

PAA feed rates of 1.2 mg/L were able to achieve average E. coli counts no higher than 41 CFU/100 mL, well below the NPDES monthly permit limit of 126 CFU/100 mL. Subsequent feed rates of 1.9 mg/L maintained E. coli maximum levels below the NPDES permit level of 941 CFU/100 mL. PAA residual was not maintained throughout the entire trial, with some instances of PAA residuals below detectable limit of the monitoring instrument, however this did not impact the deactivation of the target pathogen.

Lexington Water Systems is still feeding PAA as its primary disinfectant and is in the process of obtaining a permit modification from the State of Tennessee upon approval of the environmental analysis. Chris Wallace, Lexington wastewater operator, has been pleased with the overall success of peracetic acid and is excited to see “fish in the receiving stream outfall.”

Conclusive results of the environmental analysis have yet to be published but are forthcoming.

About the Author: Jacquelyn N. Wilson is the technical sales manager for Enviro Tech Chemical Services. Prior, she worked as a consultant, focusing on the development and use of peracetic acid as an alternative disinfectant in municipal wastewater. She has a BS from Eastern Michigan University.