By Brent Howe

Odor control covers can also collect biogas, help regulate temperatures, and reduce greenhouse gas emissions.

Unpleasant odors at wastewater treatment plants are a reminder that the plant is doing what it is intended to do: treat wastewater. Odors are an unfortunate but completely natural by-product of microorganisms breaking down biodegradable material so that treated effluent can comply with increasingly strict environmental regulations. In many ways, odors are a necessary evil.

That said, odors can have negative repercussions in and around the treatment plant. Employees’ overall job satisfaction may suffer. Neighbors may lodge complaints (which could escalate to city officials and the media, negatively impacting the plant’s reputation).

Best Intentions

Of course, the intention of a treatment plant is never to offend anyone. In many cases, the original site of the plant was secluded but gradually became more residential as the community grew and expanded around it. Suddenly, odor control becomes a priority.

It is difficult to convey to the public that a treatment plant has limited resources and competing demands for budget allocations. The community simply wants the odors gone, and the plant wants the complaints to stop.

There are many different technologies that can be applied to control odors from wastewater treatment systems. Many solutions, such as adding chemicals to the water or using deodorizing misting systems, work well the majority of the time, but a sudden change in wastewater composition or weather can cause odors to intensify. When this happens, the public might assume the plant has done nothing to combat the problem, frustrating everyone involved.

Covering the Problem

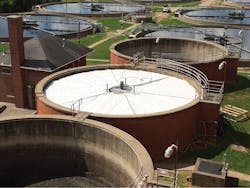

Most plants genuinely care about maintaining good relations with the local community, so a flood of odor complaints can be discouraging. Covering tanks, basins, and/or lagoons with high-quality covers is often the simplest and most cost-effective solution for odor control.

The cover should be airtight to reliably contain odors while still allowing for safe, easy access for inspection and maintenance purposes. The right cover system needs to withstand tough conditions such as chemicals from wastewater treatment, and it should resist tears, punctures, and ultraviolet (UV) rays. Ideally, the cover can be customized to meet a plant’s unique requirements and fit within existing infrastructure.

Addressing an odor problem with a cover can also:

• Reduce operational and maintenance costs

• Collect valuable biogas from anaerobic digestion

• Minimize harmful greenhouse gas emissions

• Help maintain consistent temperatures for the treatment process

• Prevent precipitation and debris from entering tanks

• Reduce chemical requirements and disinfectant by-products

• Control algae growth

There are many cover styles available on the market, including fixed covers, floating covers, inflatable covers, retractable covers, covers made from flexible geomembranes, and covers made from rigid materials such as aluminum, fiberglass, or steel. Just as there is no right wastewater treatment solution, there is no right odor control cover. It all depends on the application and the unique needs of the plant. The following mini-case studies from Evoqua’s Geomembrane Technologies™ illustrate how treatment plants can benefit from controlling foul odors with a cover system.

Odor control is the most common reason wastewater treatment plants cover tanks.

Odor Control Cover Ends Neighbors’ Complaints

The South Dearborn Regional Sewer District in Lawrenceburg, Ind., is located in an area of high population growth and is surrounded by many retail and other commercial developments. As the community grew, odor complaints became a sensitive issue. The district’s initial attempts to treat or mask odors coming from the primary clarifiers were unsatisfactory. After researching several options, South Dearborn installed structurally supported covers, and is now able to capture and treat odors from its headworks and primary clarifiers.

“Odors have disappeared from our plant,” said Dennis Feichtner, superintendent of South Dearborn Regional Sewer District.

Dairy Reduces Costs While Controlling Odors

HP Hood LLC is one of the largest dairy operators in the United States with 13 plants across the country. Its plant in Winchester, Va., was undergoing a planned expansion of its wastewater treatment system to keep pace with consumer demand.

The dairy company needed a reliable cover solution to successfully operate its new anaerobic treatment technology. Two large biogas collection covers reliably address odor concerns while allowing the dairy processor to collect valuable biogas.

Temperature, Odors Controlled with Cover Solution

The Town Branch Wastewater Treatment Plant located in Lexington, Ky., treats almost 11 billion gallons of wastewater annually. It needed to replace its end-of-life steel-dome covers with a solution that would control odors but also maintain consistent temperatures throughout the year.

Modular covers were custom-fabricated for the plant. Odors are now effectively controlled and the treatment process is better regulated. Moreover, the design allows plant operators to walk on the cover and easily remove individual panels for routine maintenance.

Reduce odor complaints by securely covering tanks located close to residential areas.

Covers on Grit Tanks Address Odor Concerns

The Georgetown Wastewater Treatment Plant located in Ontario, Canada, treats approximately 17.5 million liters (4.6 million gallons) of municipal and industrial wastewater per day. The plant was originally located in a remote area, but when houses were developed less than 100 meters (approximately 330 ft) from the plant’s property line, it didn’t take long before new residents complained about odors. The plant wanted to be a good neighbor, so it focused on its grit tanks, which were identified as a significant source of odors. Retractable covers now reliably control odors at the plant and yet easily retract, meeting the plant’s access requirements.

“We can’t chase odors in the wind. A cover makes logical sense,” said Wendy Derjugin, plant operations supervisor at the Georgetown Wastewater Treatment Plant.

If your plant is struggling with odors from wastewater treatment, it may be time to consider covering the tank or lagoon with an air-tight cover. “Capture and treat” technology is a simple, effective way to alleviate odor concerns, benefiting plant workers, the neighboring community, and the reputation of the treatment plant itself.

About the Author: Brent Howe is on the product management team for Geomembrane Technologies, an Evoqua brand. Geomembrane Technologies designs tank and lagoon covers for industrial, municipal, and agricultural customers worldwide. For more information on odor control covers, visit evoqua.com.

Circle No. 237 on Reader Service Card