Hydraulic Modeling Improves Water System Reliability, Efficiency

by Jack Cook

Antipolo City is located in the northern half of Rizal Province in the Philippines and is within the eastern boundary of metropolitan Manila. It is the second largest city in Rizal Province, with a rugged, mountainous topography.

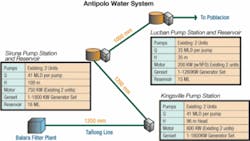

The Antipolo network system comprises three stages of pumping stations and two reservoirs. From the Balara treatment plant, water is supplied to Antipolo by gravity through the Tanong Line, which serves as the suction line to Kingsville pumping station. Water is then pumped from the Kingsville pumping station to the Siruna pumping station and then into the reservoir via the primary line (see Fig. 1).

In order to optimize the Antipolo Water Supply System, Manila Water's plan was to incorporate the anticipated rapid growth of the area from a current population of 656,000 people to 2.2 million by 2022. The utility also planned to evaluate the steady state and transient hydraulics of the preferred pipeline, pump station and reservoir combination, and to improve the overall reliability and efficiency of the Antipolo network system.

Challenges

This project presented many challenges. First, the suction line had limited capacity, which hindered maximization of the output of the first pumping station in Kingsville. The hilly terrain of the Antipolo area presented another major difficulty. Previous efforts to overcome this challenge were made by maintaining high pressure heads at the pumping stations, but the extreme differences in elevation created intensively high pressure heads in the low-lying areas, resulting in pipe breakages.

Frequent power failures, creating sudden shifts in pumping operations, presented yet another challenge (see Fig. 2). And finally, communities in the area comprised mostly low income families who got their water supply from shallow wells, private deep wells and water delivery trucks. These methods are extremely expensive and also expose the families to low water quality, which may impose health risks.

To overcome these challenges, a hydraulic model of the Antipolo water system was created. Hydraulic and transient simulations were conducted to analyze network constraints and to identify possible solutions to improve the performance of the Antipolo network. Based on the simulations and intensive field investigation, network improvement projects were conceptualized, designed and implemented.

Water modeling plan

First, the hydraulic network model was calibrated in WaterGEMS V8 XM Edition, based both on field data and the existing network database. Hydraulic and transient simulations using WaterGEMS and HAMMER helped identify critical locations in the system.

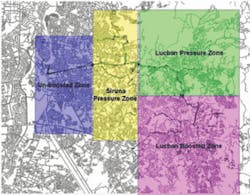

The primary reliability strategy for this project was to subdivide the water distribution network into four separate pressure zones: the Unboosted Zone, the Siruna Pressure Zone, the Lucban Pressure Zone and the Lucban Pump Zone (see Fig. 3).

Since the Unboosted Zone had constraints in maximizing the output of the water system, a parallel line coming from the Siruna Pressure Zone was installed to cover some areas of the Unboosted Zone. The strategy was to minimize the area covered by the Unboosted Zone. Smaller pressure zones were then designed by creating smaller reservoirs in areas of rolling terrain to break pressure surges due to extreme differences in elevation, and to ensure water availability regardless of interruptions in pumping operations.

Strategies to control potential transients were also identified through appropriate flow control operations and the installation of surge protection devices. Pump operation schedules were simulated using the model to come up with the most efficient scheme.

The GIS database of the existing pipe network was automatically imported into the model using the software's ModelBuilder to create the network model. Then, the T-Rex module was used to extract elevation data from the GIS database consisting of contour, topology, and GPS data. Next, Excel files of the existing and projected demands, as well as demand profiles and other hydraulic patterns of the existing network, were imported into the model.

Using the 5-year demand projection, Manila Water's engineers also ran steady-state and extended-period simulations to design the network for supplying the mountain communities and expansion areas of Antipolo.

The model was then reviewed in HAMMER for transient analysis. Several scenarios were created using different pump operations and different times of power failure, to identify critical areas affected by transients. Based on this, surge protection solutions were proposed, and appropriate flow control operations were identified.

Local Communities Realize Cost Benefits, Health Improvements

A total population of more than 709,000 people — which equates to more than 140,000 households — benefitted from the project. And, an additional 3,000 households will benefit upon completion of the network's expansion. The Antipolo Water System project will not only improve the water supply and pressure in the area but, more importantly, the people of Antipolo can now enjoy clean and potable water 24 hours a day, 7 days a week.

Using the modeling solution resulted in a significant time savings. Traditionally, it could take two to three months to create the model, but Manila Water was able to reduce that to less than a month with the new modeling solution.

Installing surge protections, such as PRVs and SAVs, at strategic locations as identified by the network model decreased the incidents of water interruption from pipe breakages from an average of 6 breakages per month to 0 to 2 breakages per month. This resulted in a decrease in leakages of 6.3 mld.

Furthermore, adjustments to the pump operation plan that were developed based on the hydraulic model and field studies, decreased the pump station operating expenditure by almost $7,000 per month.

About the Author:

Jack Cook is a Water Solution Executive at Bentley Systems, Incorporated. Bentley provides comprehensive software solutions for the infrastructure lifecycle.