In July, PennWell’s water group partnered with PUB, Singapore's national water agency, to deliver the Industrial Water Solutions Forum (IWSF) at the Singapore International Water Week 2016. The Forum brought together key industries, from food & beverage to oil & gas, to address water sustainability.

By WWi magazine

Globally, demand for industrial water equates to 20% to 25% of the total global water demand. In Singapore alone, industrial water is projected to grow from 55% of total water demand to 60% by 2030, according to Masagos Zulkifli, Minister for the Environment and Water Resources in Singapore.

Delivering the opening keynote address at the IWSF, the Minister said such growth represents 70MGD over 15 years, which is a “substantial amount for a small country like Singapore”.

Valued at US$52.8 billion, the industrial water solutions market is now seen as one of the fastest growing segments in the global water industry.

Setting up the agenda for the day and the topic - Securing Water in Challenging Environments - the minister emphasised the importance of data in water reporting.

Taking his home country of Singapore as an example, he provides the example of PUB introducing a measure for large water users to submit a Water Efficiency Management Plan (WEMP). This is designed to encourage companies to better understand their water consumption through the development of a water balance chart of their premises.

The aim, the Minister continued, is to identify opportunities for “water savings to reduce water-related risks at various parts of the process, including boilers, scrubbers and cooling towers”.

Panel Debate 1: Water Sustainability

On the theme of Singapore, Professor Asit Biswas, distinguished visiting professor at the Lee Kuan School of Public Policy, challenged audience members to ask any Singaporean if they are water stressed. To which he says they will likely answer “What is water stress?” as an indication of how the island nation has overcome water challenges.

Kicking off the discussion for the first panel debate, Cynthia Havran, downstream global discipline technology leader for water treatment & reuse at ExxonMobil, said the organisation has set out four commitments as part of its Water Management Framework.

These include: Protect human health and the environment; Consider local water needs when addressing operational requirements; Continuously improve capabilities and performance and finally Engage stakeholders in development of sustainable water solutions.

“For oil & gas, the local environment can be a significant user of water. We prudently manage the water we do use,” she says. Havran added that the organisation tries to “reduce, reuse and recycle” where appropriate and as part of an installation in Singapore, Membrane Bioreactor (MBR) technology was installed to reuse wastewater for cooling water.

Havran's comments tied in with the key theme of water reuse, discussed throughout the Forum. Decentralised water recycling efforts are now helping industrial water end users see value in water reuse.

For consumer brand Unilever, 85% of the water footprint associated with its products are at the end of the water cycle, for example in washing or cleaning, according to the next panellist David Kiu, VP, global sustainable business and communications.

He said this figure is a challenge to reduce “due to consumer habits” but as part of a campaign in Singapore, they encourage people to “shower together”, much to the audience’s amusement.

The organisation has achieved a 37% water reduction in manufacturing since 2010, against a target to halve its water footprint by 2020.

Representing the regulators, Joel Beauvais, deputy assistant administrator from the US Environmental Protection Agency (EPA), said the organisation is now working with oil operators to work on wastewater reuse and that there has been significant “interest from private companies”.

Finally, Zita Schellekens from Dutch beverage company Heineken outlined the company’s progress in reducing the amount of water it uses per litre of drink produced (see box out). By 2020 the firm has set out the target to use 3.5 litres of water, per litre produced of beer, cider, soft drinks and water.

Known to be a heavy consumer of water, the beverage industry has been questioned over the vast quantities of water it consumes. Addressing this, Schellenkens says that following studies in water scarce areas, Heineken will attempt “water balancing”, which means they cannot take more water than what the organisation gives back.

Wastewater reuse has become a household name in the water industry, with both municipalities and industries seeing the benefits but what do the big corporations make of it?

“Overall wastewater reuse is positive and there’s an opportunity to reuse and for this to happen. How to enable it is a big challenge,” says Unilever’s Kiu.

Facing the controversial question of using direct water reuse for its products, Heineken’s Schellekens says that after multiple focus groups the company concluded “consumers don’t like the idea of it and think the finished product contains cleaning chemicals”.

However, she predicts that over the next five years consumer perceptions will change as they realise they can trust manufacturers.

Chairman Professor Biswas asked if major corporations ensured that wastewater discharged met local standards when operating in developing countries. To which Havran responded that ExxonMobil sets its own discharge standards worldwide and “if local standards are lower, then we follow ours”.

Heineken’s breweries are now highly automated - there’s not a lot of people walking around and operating the plants anymore - added Schellekens. As the operation is based on data, the discharged water is “tested regularly, while helping local people understand the lab results”.

Panel Debate 2: Finance

Moving the discussion onto finance, Joppe Cramwinckel from the World Business Council for Sustainable Development opened the second panel debate with honest remarks. “The financial system has worked backwards in the past, for example looking at annual results. The question is how can the finance world impact the sustainable world?”

Bringing the discussion back to Singapore, Goh Chee Kiong from the EDB says: “Manufacturing remains a key pillar of Singapore’s economy, accounting for 20% of our GDP but accounts for about half of our water demand. That explains Singapore’s strong emphasis on industrial water solutions."

He discussed the various industrial water solutions partnerships happening in Singapore, including a project involving PUB, Meiden and SRC to demonstrate that treatment and reclamation of water from industrial wastewater using ceramic membrane technology is possible.

So how is the finance community viewing the industrial water market?

Mel Karam, global head of asset management from KPMG believes there has been a shift in the interest in water. “Gone are the days when financial companies are only interested in data,” he said. “Sovereign funds are getting involved in water as a new area. Water is a long-term resource but also a long-term investment.”

On the broader corporate responsibility agenda, Credit Suisse has signed off 58 clean-tech transactions over US$16 billion since 2010. Furthermore, according to Rony Palathinkal, over 17 billion Swiss Francs have been invested in assets according to sustainability criteria.

“When the finance community have looked at sustainability, it’s historically been a philanthropist move,” he said, adding that this is changing and Credit Suisse has been looked at projects involving China’s industrial parks, which have been tasked to “clean up their acts.”

Wilson Ang, executive director, Global Compact Network Singapore says that resource scarcity and climate change is leading people to turn to government solutions, with the private sector showing interest in sustainability.

“It’s all about asset risk,” said KPMG’s Karam. “When it comes to investment, it’s the most important factor - it has to be demonstrated that the asset risk is low.”

Karam quoted the £4.2 billion London Super Sewer project, the biggest infrastructure project ever undertaken by the UK water industry. “The Thames Tideway project attracted funds with single digit return on investment, so it is possible [for water projects to attract finance].”

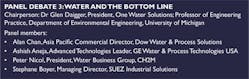

Panel 3: Water and the Bottom Line

Tthe third and final panel debate brought together a mixture of consultants, technology companies and academics.

Ashish Aneja, director at the Singapore Technology Centre for GE set out GE’s sustainability aims, including reducing freshwater consumption by 1.8 billion gallons, as well as investing $500 million in water R&D.

CH2M’s water business group president Peter Nicol said he is witnessing improvements in efficiency when it comes to water treatment. “Industrial clients are producing more yet using the same amount of water, so their efficiencies are improving.”

For French company Suez, out of its total revenues for 2015, two thirds came from municipalities and one third from industrial companies.

Stephane Boyer, managing director for SUEZ Industrial Solutions, said they are focusing more on the industrial market. Earlier in the year, Suez secured three industrial service contracts in China in the oil & gas sectors, worth 19 million euros.

Zero Liquid Discharge (ZLD) is another area where water technology companies are finding an increased appetite for their services. China’s 12th Five-Year Plan mandates the use of ZLD in new and existing coal-fired power plants and coal-to-chemical refining facilities.

Speaking on ZLD developments, Chan said: “For ZLD, in an ideal world you have nothing but solid waste left but in reality, you are left with a little bit of liquid to treat.”

Concluding, CH2M’s Nicol said the discussion used to be “focused on industrial pollution but now we talk about integrated solutions, so this shows the shift”.

The Industrial Water Solutions Forum is organised as part of SIWW. For more details visit: www.siww.com.sg/about-forum