Many Storage Tank Options, and Different Ways to Care for Them

DN Tanks

While water storage tanks are fairly sturdy structures and some have been operational for more than a century, today, water storage tanks are being constructed to replace older structures or to accommodate growing needs.

DN Tanks’ retrofit division is increasing, notes Kevin Peacock, regional manager in the Western region for DN Tanks.

“This division looks at storage structures currently in the system,” he says. “They not only study total capacity, but also consider how those tanks are operating structurally whether they are steel, concrete, or prestressed concrete. Ultimately, they will provide a proper evaluation that hopefully says “˜this structure is still good and is able to meet current codes.'”

“Are you meeting your current seismic codes? Are you meeting current state requirements as far as its air gaps and/or other items that need to be modified? Are you looking at OSHA compliance as far as the handrail, ladders, and hatches?” asks Peacock.

An engineered, bottled stainless steel potable water tank

He finds that districts look at a few factors when examining their systemwide storage. One is to calculate total capacity and the required storage for peak demands and fire flows. Structural integrity is another key consideration.

“It is always valuable to consider an older piece of infrastructure’s total cost of ownership, O&M costs, versus that of knocking it down and building new,” says Peacock.

DN Tanks manufactures AWWA Standard D110 prestressed concrete tanks utilizing a cylindrical concrete wall placed in permanent compression. AWWA D110 Type I tanks are constructed utilizing a cast-in-place concrete wall, horizontal strand prestressing, and singular threadbar vertical tensioning.

AWWA D110 Type III tanks utilize precast concrete walls with an embedded steel diaphragm. The tank wall also is placed in permanent compression, accomplished by horizontal wire-wound prestressing.

There are several roof options for Type I or Type III. Either can be built with a freestanding concrete dome, or with a column-

An engineered, bottled stainless steel potable water tank Water tank with a road and solar on the roof

supported, conventionally reinforced flat slab roof. DN Tanks also has designed and constructed dozens of tanks without roofs for wastewater and secondary water storage.

The water tanks range in capacity from 80,000 gallons or less to 50,000,000 gallons, and more. Design and engineering is customized based on the site, tank size, exterior enhancements, and other variables.

The most common tank manufactured by DN Tanks and used in the western United States is a column-supported flat slab roof prestressed concrete tank. Since the merger of DYK and Natgun into DN Tanks, there has been a slight shift to utilizing a cast-in-place dome on the top of a tank versus that of a column-supported flat slab roof, says Peacock.

“Natgun brought a lot of dome experience to the merged DN Tanks company, so we’re now able to utilize the concrete dome in some of the western regions,” he says. “Utilizing a concrete dome can help bring costs down as they’re a little more efficient to design and construct.” The company has dome tanks that are more than 60 years old and still in service today, Peacock says.

“Those tanks were constructed to older codes and older standards,” he adds. “With the evolution of the codes and the standards, we feel current design will exceed the lifespans we’re already observing on the existing tanks. We are confident that current designs can project out to the 100-year design life.”

One of the major considerations when choosing at-grade water storage or below-grade water storage is where the tank lies hydraulically within the system and where it fits within the pressure zone, Peacock says. “Without considering aesthetics, an at-grade tank will get you greater head pressure because you will have a higher elevation versus a below-grade tank, where you will have lower head pressures,” he says. “One nice advantage to burying is the ability to position a pump station on the roof of the tank. This allows for the tank to serve as the pump station foundation as well as reducing the overall site impact.

“If you’re in hilly terrain, burying the tank or placing it at grade may not matter. You can site the tank up the hill to achieve the required head pressure,” he adds. When aesthetics are a consideration, one must keep in mind that an at-grade tank is visible, sometimes for miles. This is in contrast to a buried or a partially buried tank.

Buried tanks, on the other hand, incur more costs for installation, Peacock points out.

“You must excavate to construct the tank, which may lead to a slight cost increase,” he says. “If you’re looking to bury the tank, it can serve multiple functions. We’ve constructed buried tanks with parks, basketball courts, and tennis courts on top of the buried roof. We’ve got a tank under a golf tee in the Bay area. You can do a lot of unique things when you bury the tank to get more use out of the land.”

From an inspection standpoint, “with a buried tank, you’re going to be accessing it through the roof versus an at-grade installation where it could be through the roof or through the wall, so that’s something to take into consideration,” he adds.

Peacock points out there’s a possibility that there may be a need for more tanks in California, given the state’s establishment of a maximum contaminant level (MCL) on chromium-6, a cancer-causing carcinogen, of 10 parts per billion. The state became the first in the nation to establish such an MCL. He questions whether there may be a need for a blending of water, thus requiring more tanks.

There are special design considerations with concrete tanks. “One of the best things about concrete is that you can backfill it,” says Peacock. “You can hide it and tuck it into the landscape. In working with owners and engineers on sitting tanks, we’re always mindful of how that backfill is graded around the tank. Specifically, we’ll look at the amount of differential backfill, and how that affects the tank design and ultimately the tank cost.”

Of late, the company has noted a desire to hide some of the water infrastructure components, Peacock adds.

CB&I

CB&I’s most popular offerings in the market are the Waterspheroid and Hydropillar elevated tanks; the company also supplies Composite Elevated Tanks that combine a reinforced concrete support pedestal with a steel tank.

The Waterspheroid tank is a larger-capacity alternative to the company’s original Watersphere tank. The Waterspheroid tanks have storage capacities of 150,000 to 2,000,000 gallons, and are designed for low capital and maintenance costs and a small footprint.

Standard Waterspheroid features include flush threshold steel doors with deadbolt locks, enabling easy access for authorized personnel and preventing unauthorized entry. Interior ladders facilitate access during inclement weather while minimizing unauthorized tank access, vandalism, and graffiti. The tank bell or pedestal space can be used for storage or as housing for telecommunications equipment, pumps, valves, piping, and controls. CB&I offers an optional water tank coating inspection and maintenance program.

The Hydropillar elevated tank is designed with a large, strong support pillar, an attractive appearance and a multipurpose interior space. Hydropillar elevated tanks are all-steel, all-welded structures that feature large-diameter support columns (pillars) with vertical flutes.

The pillar provides stiffness to earthquake loads, is suitable for low load-bearing soil, and unobstructed access for exterior inspection and maintenance. Its flexible design enables the Hydropillar space inside the pillar to be configured for use as offices, meeting rooms, a pump or fire station, or for equipment and machinery storage. The space also can be reserved for future expansion as funds permit. The pillar provides space for multiple floors; exterior windows can be installed.

Standard Hydropillar elevated tanks may be designed for storage capacities ranging from 200,000 gallons to more than four million gallons. The company also offers a “wine glass” design for smaller Hydropillars ranging in capacity from 100,000 gallons to 400,000 gallons. Standard Hydropillar elevated tank designs provide a 40-foot head range that minimizes pumping costs and variations in water pressure.

The Composite Elevated Tanks (CETs) combine the tensile strength of steel with the compressive characteristics of concrete. CETs are designed with reinforced support pedestals and stainless steel risers to require minimal maintenance. CB&I offers straight, truncated tank designs as well as Waterspheroid tanks.

All CETs feature solid, flush threshold steel doors and internal access ladders. The pedestal may be designed with an interior control room and additional space that can be used for offices, fire stations, and other facilities. Other options for the tanks include heat tracing, dual risers, roof handrails, free-span floors, seal welding, cathodic protection, lightning protection, altitude valves, fail-safe roof vents, and lighting.

CB&I also builds reservoirs–also known as ground storage tanks–and standpipes, ground-level water storage tanks that can be built to any capacity and dimension. Reservoirs have a greater diameter than height, and standpipes have a greater height than diameter. The tanks have ranged in capacity from less than 1 million to 34 million gallons.

Reservoirs offer economical and effective storage, especially when located on high ground. Their low profiles enable them to be concealed by foliage. Standpipes’ taller design enables water above the operating range to provide gravity-fed pressure; the water below the standpipes’ operating range provides reserve storage.

The reservoirs and standpipes are constructed entirely of welded steel for leak-free service and are suited for high seismic zones or high wind load applications.

CB&I provides turnkey services, including preliminary planning, design, foundation construction, fabrication, tank construction, painting, and maintenance. The tanks are designed with standard features such as manholes, painted ladders, overflow to grade, anti-climb guards, roof handrails, fail-safe roof vents, and inlets/outlets with silt stops. The tanks can be designed with ellipsoidal, toriconical, dome, or cone roofs.

Optional features include lettering, logos and decorative graphics; decorative pilasters; safety cages; balconies; external lighting; telemetry; and cathodic and lightning protection. Also optional is the FreshMix circulation system, designed to ensure that fresh water and chlorine residual are maintained throughout, eliminating taste and odor problems that may result from stagnation.

Which tank is best for a particular site depends on customer preferences, says Richard Horn, regional sales manager for the Midwest. “There are some differences throughout the country where different styles are what seems to be what people want in that area,” he says. “Sometimes they are design related. Hydropillar does very well in high seismic areas. Composite tanks don’t and spheroids are somewhere in the middle.”

Soil conditions and capacity needs are also factors.

“With smaller capacity tanks, spheroids are certainly much more economical,” says Horn. “When you get into the very large tanks—2.5 million gallons and above—then the Hydropillar and composite tanks become much more economical.” The tanks are constructed to the AWWA D-100 standard.

Coatings continue to improve for welded steel tanks, says Horn.

Horn points out that with belowground tanks, it costs more to excavate and build them below ground. Not only do they have to keep water in, but also keep groundwater out. “There are additional pumping costs, not only to get the water out of the ground, but then distribute it to end users,” he says.

With aboveground storage tanks, gravity does some of the work in water distribution, he adds. That provides greater efficiencies in electricity costs, especially during times of peak demand that normally occur between 4 p.m. and 9 p.m., Horn points out.

“You have to have much bigger variable pumps to pump during that time period to meet the peak demand for water which also is the peak demand for electricity,” he says. “You might be paying as much as 12 cents per kilowatt-hour, as opposed to if you pump during the night for four to eight cents up into an elevated tank, or the top of a standpipe, or even a ground storage tank on the side of the hill, and allow the gravity flow to feed your distribution end users during that peak demand period. You’d save all of those utility costs at those peak hour rates.”

In sizing a tank, the rule of thumb is to get at least one day of storage in the tank. “You size your tank for that one-day need and add your fire protection needs on top of that—another 40%—and then you need to add for the growth of your community, if you’re going to have any, by taking your average daily demands and projecting those for your population growth,” says Horn.

Schools, some industries, hospitals, and other facilities use more water, and that needs to be factored in as well, he says. Another consideration is summer demands for water: irrigation, washing cars, people taking more showers, and drinking more water.

American Structures

American Structures fabricates bolted, stainless steel tanks. The company also serves as the distributor of Fusion Glass Fused to Steel tanks for end users seeking an alternative tank application.

The company also provides geodesic domes, flat steel, knuckle-style, and 1:12 pitch steel roofs, and recently added the ability to provide membrane-type covers for its tanks. American Structures became a distributor of Rhino Industrial Lining Solutions for tank customers who favor stainless steel. The impermeable lining is available up to a 60-mils thick industrial elastomeric coating for the inside of the tanks for a variety of applications.

There are many benefits to bolted, stainless steel tanks, points out Rosemarie Bristol, marketing and sales manager for American Structures. “They are environmentally friendly, maintenance-free, and have a product life expectancy in excess of 40 years. They do not require coating before use and never have to be painted, regasketed, or welded, but can be should the customer so desire,” she says.

“They are stain-resistant and rust-free; able to store most types of materials; 100% recyclable, helping to preserve the environment and reduce waste; fire and heat resistant, allowing for storage of liquids in process; compatible with the surrounding landscape; strong and durable with a high strength-to-weight ratio; and impact resistant, ensuring higher levels of safety.”

Tanks can be operative in excess of 100 years. The Steel Tank Institute/Steel Plate Fabricators Association lists more than 24 entries into its Century Club, which recognizes utilities that have properly maintained their steel pipe components, resulting in 100 years of service in the delivery of clean drinking water.

Example of tank with tennis court on roof

There are those who have the perception that stainless steel tanks are more expensive than other types of tanks, Bristol says, adding that the company’s tanks are competitively priced in comparison to other types of tanks. “When you apply the many advantages of stainless steel, especially their sustainability, versatility and flexibility, as well as their low or no maintenance requirements, they actually offer a viable and substantial savings over the long-term lifespan of the tank,” she says.

Aesthetics can be a challenge with aboveground tanks, Bristol points out. “Our tanks are attractive, blend in well with the environment and do not rust or corrode,” she says.

Financial viability can be another challenge. “Bolted, stainless steel offers some major advantages in this area, especially given the longer lifespan of the tanks, their versatility in being able to be reconfigured, added to, or taken down and relocated,” says Bristol.

Tank Connection

Tank Connection has four manufacturing plants in the United States that are servicing the requests for above-ground storage, RTP (rolled, tapered panel) bolted tank construction in the industrial and municipal water market, says Bill Neighbors, president and CEO.

Tank Connection’s bolted RTP construction features sidewall plate thickness up to one-half inch plate. Bolted RTP liquid tanks are available in sizes up to 8 million gallons. Field construction is accomplished utilizing a synchronized, hydraulic screw jack process, which keeps field crews on the ground for safety and quality control.

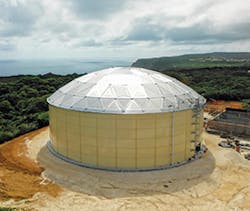

Aluminum geodesic domes are being installed as the cover of choice in water storage, Neighbors adds. “They are routinely installed on concrete, field-welded, and bolted storage tanks storing potable water,” he says. “The preference for this product is because aluminum geodesic domes require minimal maintenance.”

Aluminum Geodesic Domes are designed for various liquid containment applications and tank construction including bolted steel, field-weld and concrete construction. For bolted steel tank construction, Tank Connection offers LIQ Fusion 7000 FBE as a powder coating system.

Neighbors notes a worldwide preference for a hybrid storage tank product that performs well in ground reservoirs. “The tank configuration includes a concrete foundation and base, RTP bolted tank sidewall construction, and an aluminum geodesic dome cover,” he says.

At Anderson Air Force Base in Guam, P&S Construction worked with Tank Connection to install a 1.5 million gallon potable water storage tank utilizing those components, as well as the LIQ Fusion 7000 FBE powder coating system. One of the challenges of the project was meeting the criteria as outlined in the Army Corps EM 385-1-1 Safety and Health Requirements Manual, which governs all projects on military bases.

Bolted RTP and welded standpipes continue to be an economical choice for elevated water storage, Neighbors says. “In elevated water tanks, there is developing interest in a design that is economical to install, has great aesthetics, and requires low maintenance,” he says, adding that in 2014, Tank Connection will be releasing an elevated water tank design that will satisfy all three parameters requested.

The benefits offered by aboveground bolted RTP steel storage include high quality, low maintenance, water containment purity, and low installation cost, says Neighbors. “When you have a problem below ground, you have a real problem that can typically only be patched,” he says. “We receive few requests for belowground water storage tanks.”

When it comes to constructing or replacing a tank, utilities need to understand what they are specifying and procuring, says Neighbors. While web stiffeners—tank reinforcement bands—continue to be used on more bolted water tank installations, they “allow the tank sidewall plate thickness to be decreased,” he contends. “Do you want a water storage tank designed with adequate plate thickness, or a thin wall storage tank that is reinforced with bands and stiffeners? Do you want a water storage tank that will stand the test of time, or a product that needs replaced in 15 to 20 years?”

Tank Maintenance

Neighbors points out that utilities should specify several alternatives, then review product offerings and associated costs. He also affirms that once water storage is constructed onsite, it’s critical to establish a routine inspection plan and stick with it. Provided a tank is manufactured with structural integrity, maintenance is the key to its longevity. The kind of maintenance depends on the material, DN Tanks’ Peacock points out.

“There are different considerations,” he says. “With steel tanks, there are structural coatings and linings where the tank structurally needs to have those coatings to protect the steel. Those coatings must be removed and replaced over a set period of time depending on their wear and tear. Steel tanks also may require cathodic protection.”

Prestressed concrete requires no structural coatings or linings, resulting in one less maintenance issue, Peacock says. “With concrete tanks, we always let people know that just because there are no coatings, there is still the need to perform inspections for silt and make sure the tank is operating properly. An inspection is also good for making sure nothing gets inside your tank that you don’t want in the tank,” he says.

DN Tanks advises tank owners to have an inspection conducted every three to five years on any type of tank. “It’s always good to check the ladders, hatches, and vents for concrete tanks to make sure those are wearing well over time,” he says. “Piping is another point to be cognizant of when performing those inspections.”

In doing maintenance, Horn says: “Somebody needs to go in there and look at the tank, not just open the door at the bottom and look up and around. They need to take the tank out of service, empty the water, climb up into it, look at the roof, look at the insides, see what the conditions are, and look for any areas that might need spot touch-ups with paint and fix them.”

Horn tells the story of one end user who called him 12 years after buying a tank from CB&I to see if the company had a key to the tank. “You’re kidding me,” replied Horn, adding that the end user hadn’t been in the tank for a decade.

For those who choose not to do maintenance on their own, Horn points out there are tank inspection companies and consultants who do so.

“You need to climb the tank,” he says. “You need to be able to train for that and be able to look at the conditions of the tank just like a car. Making repairs as needed will prolong the longevity of the tank.”