Public water suppliers typically need three types of potable water storage: equalization, fire suppression, and emergency. Although any or all may be included in a single storage facility, each has a specific purpose and specific requirements.

Before the design of storage facilities can even begin, their sizes must be identified in the planning phase. Volumes for each storage type must be allocated in each pressure zone or service area. But how?

“There are many ways to determine the size of a potable water tank, but they mainly have to do with the facility being served, what the expected use profile is, and how often the water in the tank can and/or will be replenished,” says Ted Cotton, territory sales manager of water products for Xerxes Corp., a manufacturer of fiberglass tanks.

Here, several water utilities and contractors offer their perspectives on water storage planning.

Equalization Storage

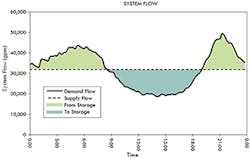

Equalization storage (also called operational storage) balances supply and demand during daily operation. Since source production does not always follow demand, storage makes up the difference. During low demand, sources produce more water than is needed and the excess water is stored. During peak demand, sources cannot keep up, and the supply must be augmented by stored water. This type of storage equalizes the day-to-day fluctuations and allows the system to breathe.

“Equalization storage describes how a water tank equalizes the flow into the distribution system during maximum-hour demands and refills during minimum-hour demands, so that pumping and treatment plants can be designed and sized for maximum-day demandsrather than maximum-hour demands,” says Arnie Strasser, manager of treated water planning at Denver Water.

For example, residential water demand in the West includes indoor and outdoor uses during the summer. Demand is high overnight when most irrigation occurs, but is low during the day. Sources may produce water at a constant rate. The difference between supply and demand is equalization storage. Equalization storage fills during the day and depletes overnight, though the average demand and average supply are similar. In this way, water utilities enjoy the advantage of large “batteries” to buffer loads without dispatching more sources.

According to Sonia Allman, manager of strategic communications for Metro Water Services (MWS) in Nashville, equalization storage is for “shaving off peak demands at pumping stations.” Indeed, meeting peak demand with storage rather than pumps is a best practicefor efficiency.

Several water managers recommend using computerized hydraulic models to determine storage sizes. “Denver Water utilizes a sophisticated distribution system model to replicate the actual physical system,” says Strasser. “This model is calibrated at current demand conditions, and then projected models with future system demands are created from that to help us determine whether the storage is adequate or if it needs to be resized.” The City of Tallahassee follows a similar approach. “For planning purposes, water distribution system elements have been programmed into a computer model, which is used to evaluate present and future water main and storage capacity needs based upon population increases, water demand, and fire flow,” says

Jennifer Porter, the city’s water planning program engineer. Allman likewise acknowledges the role of hydraulic models for determining sizes. A model, however, is insufficient by itself and needs proper engineering insight. This approach, when combined with satisfying regulatory criteria, ensures efficient design for both required and actual projected storage volumes.

Regulatory criteria for equalization storage vary widely. In some states, the requirement is based on the number of connections. Utah, for example, requires 400 gallons per connection for indoor use. Others require that the equalization volume be specified as the difference between source flow and demand over a certain period of time; Idaho specifies two such methods. Another common criterion, accepted in California and elsewhere, is that equalization storage must be at least 25% of the peak-day water volume. According to Strasser, “Denver Water’s total storage volume is designed to be half equalization and half emergency storage, which includes [fire flow], based on future maximum-day demands.” Portland (ME) Water District (PWD) applies similar criteria. “For the purposes of evaluation, values of similar water systems were used on [a] zone-by-zone review,” says Gordon Johnson, PWD’s engineering services manager. “This resulted in using estimated equalization storage volume targets of 15 to 25% of maximum day demand.”

Home rain barrels collect and store rainwater for later nonpotable use.

While some water utilities prefer to “always keep the tanks full,” using equalization storage offers several benefits, among them pressure regulation, energy efficiency, and water quality.

Since demand is not constant, some pressure fluctuation is normal. A tank that “floats” on the system can suppress extreme pressures and supplement low pressures. During peak demand (low pressure), the tank can supply additional water, beyond regular sources, to maintain pressures and meet demand. During low demand (high pressures), the tank’s overflow can limit the pressure buildup that would otherwise occur.

Energy is a major operating cost for water utilities—up to 40%, according to EPA and other groups. Many power companies charge time-of-day rates to incentivize customers to use electricity during periods of low power demand. (Unlike water utilities, power utilities cannot store their product in bulk and must be able to generate peak instantaneous power.) Adequate equalization storage allows a water system to pump water at a cheaper off-peak rate and supply it, by gravity, during peak water demand. Optimizing rates and operations in this manner has saved some water utilities 30% on their power bills.

Water quality is another benefit of equalization, which promotes mixing and avoids stagnant water. Poor mixing can occur if the turnover is small compared to the tank size, or if equalization storage is not well-used. A well-designed system exercises the tank; Johnson calls it “active tank cycling.” Equalization allows water levels to rise and fall daily, periodically mixing the storage contents and controlling the water age, a factor that contributes to the formation of undesirable disinfection byproducts. In Tallahassee, says Porter, “the water system operators drain and refill the working volume of each storage tank on a daily basis to maintain the quality of the water.” As a best practice for managing water age, the Water Research Foundation recommends that stored water be turned over at least every 2½ days. If the turnover is longer, the operating range may be increased or the active volume may be decreased.

Some water utilities are even decommissioning their tanks to promote turnover. “The analysis of historical pumping and storage patterns showed relatively low equalization storage

volumes,” says Johnson. “The last storage tank PWD constructed was in 1998. Since that time, four tanks have been removed from service to improve water quality and reduce maintenance.” Denver Water has done the same. “Over the past 10 years, we’ve been downsizingstorage tanks to provide just the right amount of storage, which optimizes our water quality,” says Strasser.

When planning a storage facility that will fulfill multiple purposes, equalization levels should be defined. For example, the top 10 feet of an elevated tank may be dedicated to equalization storage. Operators then know that any fluctuation in that range is normal. Equalization levels should be determined from a thorough engineering analysis that considers regulatory requirements as well as actual turnover.

Fire Suppression Storage

Another function of water storage is to provide an immediately accessible supply for firefighting. Sources cannot not always provide the needed fire flow (NFF), especially in small systems. Instead, a certain water volume should be reserved for suppressing fires.

Fire suppression storage must consider both the flow rate and the duration of the fire event. For example, a school fire may require 4,000 gallons per minute to extinguish, over a period of two hours (120 minutes). The required fire suppression storage in the tank serving the school is the product of the flow and its duration, in this case 480,000 gallons. The same principle applies for individual buildings with their own fire sprinkler and storage system.

For small water systems, fire flow and the associated storage are often the governing design factors, being much larger than daily demands. In large systems, however, typical demand far exceeds a fire condition. “Because of the extensive size of Denver Water’s distribution system, fire storage is usually not the controlling condition for storage design,” says Strasser. “Most of the NFF volume is for residential fire protection, which is typically much smaller than the size of our tanks. There are exceptions in our system, like at Denver International Airport where the storage volume needed is based on the NFF requirement multiplied by the duration of the NFF.”

“Fire demands are typically stipulated by the International Fire Code in conjunction with the International Building Code,” says Allman. “We exceed that in some areas near transmission mains and not so much in rural areas. Water age or quality has to play a role in determining maximum flow rates. The [code] allows for a significant reduction of fire protection for new buildings if fire sprinklers are installed.”

by the shaded areas between the two lines.

Other water utilities, such as the Greensboro (NC) Department of Water Resources, specify a minimum total volume for fire suppression storage. According to Barry Parsons, the department’s water supply division manager, “our fire suppression is based on maintaining a 60% total storage capacity at all times. Although some of our storage tanks are turned over and drop below the 60%, our average is always above 60% based on daily demand.” Parsons adds that the fire department’s insurance also stipulates the NFF storage.

Fire suppression storage must consider all building types and sizes in the service area. Large buildings such as schools, apartments, and commercial centers require more firefighting capacity than single-family homes. Most states require coordinating with the local fire marshal to ensure that fire suppression storage in each service area is adequate.

Emergency Storage

Though one hopes that serious failures will never occur—a mainline break or source contamination, for example—they invariably do. For this reason, water systems plan emergency storage that can maintain pressure, provide an alternate supply, or bypass a damaged area during such events.

“Once we had a large transmission main fail that flooded the access points to the streets and valves needed to isolate the break,” relates Strasser. “By the time other isolation valves were located and we were able to isolate the break, about 15 million gallons of water [hadbeen] sent into the distribution system from a nearby storage tank, helping maintain positive pressure. Without this additional storage, the distribution system could have run dry in the area of the break, potentially causing water-quality issues.”

Greensboro has also had occasion to use its emergency and fire storage. “Over the years, emergency storage capacities have been challenged due to three-alarm fires, water breaks, etc., and have performed very well,” says Parsons.

MWS has “used storage many times for an emergency basis whenever we might have a significant break in a critical water main. It always performs well,” says Allman, adding that gravity flow is the most reliable backup.

The desired emergency volume depends on the utility. “A general target for emergency storage has been the volume equal to the average-day demand,” says Johnson. “During the evaluation, the availability of standby power, pumping capacity, transmission main redundancy, and pressure zone interconnectedness was considered to determine the need for emergency storage.”

Not every tank may need to have emergency storage, but each zone or system should. In Tallahassee, “the eight water storage tanks in the system were not designed for specific fire or emergency storage volumes; however, the entire system operates as a unit,” says Porter.

The choice between ground-level and elevated storage is particularly important for fire and emergency scenarios.

Ground-level storage requires high-service pumps and backup power that may be subject to the same failure modes

that cause other service interruptions. The American Water Works Association and the US Federal Emergency Management Association both acknowledge that elevated storage provides the best, most reliable, and most useful form of storage, particularly for fire protection and other emergencies.

Adding It Up

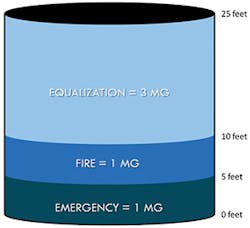

Once volumes for equalization, fire suppression, and emergency storage are determined, their dedicated spaces in the tank should be defined. Although water constantly mixes and the volumes are not actually stratified, visualizing a “stacked storage model” can be useful for planning purposes.

In such models, equalization storage is located at the top. This promotes the concept that fluctuation within that space is acceptable. In the figure shown, the top 15 feet are dedicated to equalization storage. During daily operation, the water level may rise and fall in response to demand, but should not descend below (or approach too close to) its designated boundary. Emergency and fire storage are represented at the bottom to illustrate their constant availability. In this example, the lower 10 feet are reserved for those purposes. Similar to Greensboro’s 60% policy, this volume should be available at all times, though the upper portion may turn over daily. Not every storage type may be necessary in each tank; sometimes entire tanks are dedicated to fire suppression. Regardless, their relative volumes and locations should be understood during the planning phase.

Large tanks for city-scale water systems usually require custom design and construction with concrete or steel. Still, some prefabricated products are available for smaller applications. Cotton recommends Xerxes fiberglass tanks for particular uses. “Potable water applications range from small cisterns for residences or properties needing extra storage for a low-producing well, to commercial applications, to municipalities needing storage [for] chlorine contact for treatment of drinking water,” he says. “Compared to other materials such as concrete, steel, or polyethylene, fiberglass offers great strength-to-weight ratio, is very versatile and customizable, and has great long-term corrosion resistance.” The prefabricated tanks reduce design and construction costs and are especially useful in areas where minimal construction disturbance is desired.

Once volumes are determined, a suitable site must be selected. Many factors constrain potential storage sites, including elevation, proximity, and land availability. “Generally, the criteria for a treated-water storage tank is to be able to provide adequate pressure to the area it will serve. Denver Water requires the minimum pressure to be no less than 40 psi and the highest pressure not to exceed 110 psi,” says Strasser. “The ideal location for a treated water storage tank is in the middle of the area it serves and at a high enough elevation to provide adequate pressure to the customer located in the highest area.”

When planning Nashville’s water storage facilities, MWS considers elevation, distance from transmission main, and its location with respect to the pumping station within a pressure

zone. In Greensboro, “all of our storage sites are based on hydraulic grade lines,” says Parsons. “A good site will have good elevation and an area of adequate use to minimize water age.” Allman recommends sites that will require minimum cut and fill and thereby reduce costs. A thorough geographic and engineering analysis, with input from the public and stakeholders, is usually necessary to determine the optimal site.

Tanks also present opportunities for other public uses. Water towers often display city names, signage, or art. Buried and partially buried tanks have been topped with parks, volleyball courts, landscape features, and local monuments that make the site both aesthetic and functional. Such dual-use options may be considered during the planning process.

Measuring Performance

A water tank is a significant capital investment. Once built, it should be inspected regularly to ensure satisfactory performance. Such issues may be considered during the planning phase. The American Water Works Association recommends that water utilities ask the following questions:

- What frequencies and levels of inspection are necessary?

- What should be on the inspection checklist?

- How will we ensure the tank’s safety, sanitation, and structural integrity?

- How often will we measure chlorine residual and disinfection byproducts?

- How will we check for thermal and chemical stratification?

- How will we prepare for emergencies?

- How will we maintain an adequate level of service?

Utility Service Group (now Suez Water Advanced Solutions), offers special services to ensure that water tanks perform their best. The company “provides complete asset maintenance including high-performance coatings, heavy repairs, upgrading older tanks to current standards, and extending the life of assets indefinitely to ultimately keep the community’s water supply safe,” says Jonathan Cato, the group’s vice president of tank and concrete services. “Understanding that many communities’ financial resources are stretched, we can provide all of these services and maintain assets through flexible financial solutions to fit most communities’ budgets.”

As a major component of public water systems, storage deserves proper attention through all phases of planning, design, construction, and operation. How might overall performance be measured? “By providing the best water quality to the customer,” says Strasser.

Save It for a Rainy Day

The growing popularity and practicality of rainwater harvesting have created a demand for special storage solutions. It is an alternative water supply that can be implemented almost anywhere it rains. Rainwater may be captured on roofs and other surfaces and stored, thereby offsetting certain water uses at a given site.

“This has probably been our fastest-growing application in recent years,” says Ted Cotton of Xerxes Corp. “Typically Xerxes rainwater harvesting tanks are used to collect rainwater from the roof of a building and store it for non-potable applications such as irrigation, vehicle washing, or even flushing of toilets and urinals.”

Mike Ruck of Rain Water Solutions adds that in areas of above-average rainfall, rainwater harvesting can control flooding and protect water quality by intercepting runoff.

Though rainwater harvesting systems vary in size and complexity, they all require a storage device. For commercial and institutional applications, large aboveground or buried tanks may be necessary. For household applications, a 55- or 200-gallon rain barrel is typical. Discounted barrels and rebates are available through water conservation programs in several areas. Rain Water Solutions manufactures and distributes products for such programs.

“We work with residents, local and state agencies, and public and private institutions to develop custom solutions with the intent of protecting their landscape investment and reducing the use of costly treated water,” says Ruck. “We specialize in helping these partnering agencies to run and manage successful rain barrel programs—getting citizens involved with local water issues.”

Since 2013, Binghamton University’s rainwater harvesting project collects runoff from campus parking lots, roofs, and other locations and recycles it in the university’s cooling towers and toilets. Containment Solutions, another fiberglass tank manufacturer, provided 200,000 gallons of storage for the project. Four 68-foot-long, 50,000-gallon tanks were installed to store the water underground.

“This is the largest rainwater harvesting (project) in upstate New York,” said Bill Hall, university architect, in a statement.