Mixing Systems Insure Adequate Disinfection

By Donald Ruehrwein

Everyone wants safe, fresh drinking water. The water supply industry in the United States does an excellent job of providing drinking water in which pathogens and taste- and odor-producing microorganisms have been reduced to safe levels, in part by using disinfection as a critical process to attain high quality water.

Of course, disinfection requires more than just injecting a chemical into the water. During the water treatment process, adequate contact time must be provided after injection to ensure that the microorganisms present in the water are inactivated before the water is distributed to consumers. And in the downstream distribution system, stagnant areas must be avoided in order to prevent dissipation of the disinfectant and regrowth of the microorganisms.

The Chicago Bridge & Iron Company (CB&I) offers two simple, economical systems to improve disinfection performance after the chemical is added.

Disinfectant Contact Time

The 1989 U.S. Surface Water Treatment Rule (SWTR) requires that suppliers provide disinfection to inactivate various microorganisms. Specific CT levels must be attained during the disinfection process. CT is defined as the residual disinfectant concentration (C, mg/L) multiplied by the effective contact time (T10, minutes). The SWTR Guidance Manual specifies CT requirements.

The theoretical detention time, T, in a contact tank (or "clearwell") is calculated by dividing the tank volume by the inlet flowrate. The effective contact time, T10, will be smaller than T because water does not flow evenly throughout the entire tank; flow can "short-circuit" through portions of the tank, taking a relatively direct path between the tank inlet and outlet and leaving low-flow "dead zones" in other areas of the tank.

Many design approaches have been used to improve baffle performance and contact time of clearwells. For example, both rectangular and round tanks have been fitted with a number of straight interior baffle walls in order to create a serpentine flow path. Round tanks have also been fitted with curved baffle walls to create a long spiral flow path. Generally, as the amount and cost of the baffling has increased, performance has improved.

Ribbon Flow Clearwells™

One option is CB&I's Ribbon Flow Clearwell, which uses relatively small, simple baffles on the inlet and outlet of the clearwell to improve performance with minimal baffling. The inlet baffle creates a narrow, full-height opening against the tank wall that results in a tall, thin ribbon of water entering the tank. The outlet baffle has a similar long narrow opening extending the full height of the tank. Due to the influence of these baffles, the flow tends to follow a long spiral path from the inlet baffle to the outlet baffle.

The Ribbon Flow was first employed in two 112 foot diameter by 16 foot high clearwells in Carbondale, IL Tracer tests performed on those tanks demonstrated a T10/T ratio of 0.67. To date, the system has since be used in five locations.

The advantages of the Ribbon Flow clearwell include:

- It allows the use of smaller tanks, thus reducing costs and space requirements.

- The inlet and outlet baffles remain effective during changes in either flow rate or tank water levels.

- It can be made to resist seismic loads very economically.

Storage Tank Performance

The drinking water that leaves the treatment plant is still in danger from the regrowth of microorganisms, or from the introduction of new microorganisms, within the distribution system. These microorganisms can cause disease or create unpleasant tastes and odors. To counter these potential problems, water suppliers strive to maintain a residual disinfectant concentration throughout the distribution system.

Water typically both enters and leaves water storage tanks through bottom connections. This can result in a large volume of unused water in the top of the tank moving up and down, essentially as a stagnant "piston" of water. The disinfectant contained in the entering water can dissipate to ineffective levels before reaching the upper stagnant water, allowing microorganisms to grow there. When an unusually large amount of water is withdrawn from the tank, the upper stagnant water with its microorganisms may be distributed to consumers.

Draft Tube Ejector Mixing System

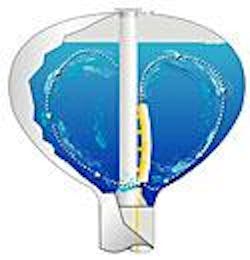

CB&I's FreshMix% system is a simple system that applies the well-established technology of draft tube ejectors in order to distribute fresh, disinfected inlet water throughout a water storage tank. The system consists of a nozzle on the end of the inlet pipe and a vertical draft tube. Incoming water flows through the inlet nozzle into the draft tube, where it educts or "drags" stored water along with it, resulting in a significantly higher mixing flow rate and thorough mixing. When the combined water stream exits the top of the draft tube, it then mixes with the water in the top of the tank before ultimately returning to the tank bottom.

The FreshMix system has no pumps or other moving parts and is powered solely by the normal motive flow of water entering the tank, thus yielding minimal operating and maintenance costs.

CB&I first applied the system for potable water service in 1997 in a 5 million gallon standpipe in Springfield, IL. A 2,000 gpm inlet motive flow produced a total flow rate of 10,000 gpm in the draft tube. The FreshMix system mixes the entire standpipe contents in approximately 8.3 hours, and tests demonstrated that the system maintained a constant chlorine concentration throughout the entire tank.

CB&I has also applied the system to elevated storage tanks. In this application the company curves the draft tube partially around the tank's internal access tube in order to prevent the access tube from interfering with mixing and also to impart a beneficial swirl to the water.

The FreshMix system was installed in an elevated storage tank in Normal, IL, in 2001. Some of the tank's 500,000 gallon storage capacity was intended to serve the city's future population growth, but a relatively high water level had to be maintained in the tank to provide adequate water pressure. The city was concerned that stagnant water tastes and odors would develop in the tank's excess volume during its initial years of service. Using an inlet motive flow rate of 2,000 gpm, the system is designed to create a total flow rate in the draft tube of 6,000 gpm, mixing the tank contents in approximately 1.4 hours.

About the Author

Donald Ruehrwein is Chicago Bridge & Iron's Product Manager for water treatment equipment and is a co-inventor of the FreshMix system, U.S. patent number 5,735,600. He presently works at CB&I's office in Plainfield, IL.