New Technology Repairs Leaking Pipes

By David A. Davies, Barton Davis and Douglas Adams

Advances in composite resin and epoxy technologies along with a better understanding of modern pipe leak dilemmas have resulted in the evolution of pipe repair systems that address a variety of repair and reinforcement requirements.

The leak sealing capabilities of water-activated polyurethane adhesive resins and the reinforcement capabilities of knitted fiberglass have been combined with the void filling qualities of fast setting polymercaptan epoxies to create a new group of leak repair products.

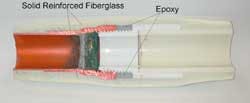

Resin coated fiberglass tapes harden into solid reinforced fiberglass in less than five minutes, and cure completely in around 30 minutes. By encapsulating epoxy plugging compounds with these fast-curing resin coated fiberglass tapes, the integrity and life expectancy of repairs has been increased to the point where these repairs can even be considered permanent.

Epoxy compounds by themselves have long been used to make quick, temporary repairs to damaged piping in antiquated municipal sewer systems and by commercial divers to fill cracks and holes in underwater concrete pipes. The consistency of the epoxy makes it ideal for plugging holes caused by corrosion, filling leak sites in threaded couplings and stress cracks in damaged piping.

It is important to insure that the epoxy used in these systems is ANSI/NSF Standard TANDARD 61 certified as safe for potable water use if repairing drinking water systems, as some of the available products meet these requirements while others do not. The Stop It® Pipe Repair System manufactured by InduMar Products includes Fix Stix epoxy that is NSF certified.

These water-activated repair systems are adaptable to many different pipe leak situations. The elastic knitted formulation of some of the fiberglass repair tapes makes them highly conformable around complex fittings, elbows and tees. The fiberglass tape's adhesive polyurethane complements and enhances the epoxy repair by adding its own sealing powers. These systems have excellent pressure retention capabilities, short cure times and are resistant to temperature extremes.

The Stop It® Pipe Repair System may be applied completely underwater, often with gravity flow pressure still on the pipe. It is also compatible with numerous types of most chemicals and will not degrade when coming into contact with them.

The application is simple. The roll of conformable knitted fiberglass tape comes pre-coated with water-activated polyurethane resins. Once exposed to water, the resins coating the fiberglass roll are instantly activated. Multiple layers of the slightly elastic knitted fiberglass tape are tightly wound around the damaged area. Tight wrapping aids in the expansion of the polyurethane resins and gives the repair a strong mechanical bond in addition to, in some cases, a chemical bond, which fully encapsulates each layer of the wrap. This is critical for the repair of badly corroded steel piping and for applications on materials that are otherwise difficult to adhere to, such as ductile iron and thermoplastics. Consequently, a repaired leak site has the added benefit of structural reinforcement.

With these systems, thin wall pipe thickness may be built back up and repairs to damaged joints will eliminate further coupling failures due to water hammer, ground movement, improper snaking or thrust blocking. PVC compression slip couplings can also be reinforced to add tensile strength. The Stop It® Pipe Repair System has been shown to add over 2000 pounds of additional pull out strength to a PVC coupling, whether properly solvent welded or not.

About the Authors: David A. Davies is Marketing and Sales Manager for InduMar Products, Houston, TX. Davies spent eight years in the water treatment industry with Ionics, US Filter and Culligan. Barton Davis has been with InduMar for 14 years and has extensive experience in all aspects of leak repair. Douglas Adams is a Marketing Assistant at InduMar Products.