Study Examines Corrosivity of Mixed Oxidants, Sodium Hypochlorite

A four week bench-scale corrosion study was conducted earlier this year by C&E Engineering Partners Inc. on behalf of the Town of Westerly, RI. The town was seeking the Rhode Island Department of Health’s approval of a mixed oxidant disinfectant. The goal of the test was to conduct a head to head comparison of Westerly source water disinfected with either MIOX mixed oxidant solution (MOS) or sodium hypochlorite (bleach) to determine relative rates of corrosion and generation of disinfection byproducts.

Each week, 10 gallons of untreated source water was collected from the same well field for use in the bench scale testing. In order to simulate the treatment conditions of the Westerly municipal distribution system, the pH of the water was adjusted to 8.0 with potassium hydroxide and 1 mg/L polyphosphate corrosion inhibitor was added.

In the corrosion studies, lead and copper coupons, as well as copper coupons partially coated with a 50% tin/50% lead solder, were procured from Alabama Specialty Products. The coupons coated with the solder mixture were used to simulate a soldered copper joint. The coupons were attached to a 2.5 inch plastic holder rod that was securely attached to a 1 liter HDPE plastic jar. The jars were securely covered. Each type of coupon was tested at two different concentrations, 0.2 mg/L and 1.2 mg/L free available chlorine (FAC). In total, 12 jars were used to complete the weekly corrosion studies.

After one week of exposure to the coupon, water was removed and collected for analysis. Once the samples were collected, the jars were refilled with freshly treated source water that had been adjusted to mimic the Westerly water treatment process. The collected water was then tested for total copper, total lead, or in the case of the mixed solder coupon, both copper and lead using EPA method 200.8. Analyses were conducted by an independent analytical laboratory.

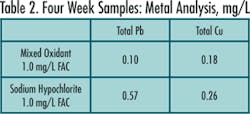

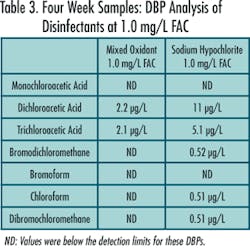

In the residual and disinfection byproduct studies, additional pilot tests were set up for an extended 4-week exposure to determine the durability of the chlorine residual, total copper and lead concentrations from extended exposure, and trihalomethanes (TTHM)/haloacetic acids (HAA5) formation potential.

In these studies all three coupons were treated in one jar at 1.0 mg/L FAC concentration with either MOS or sodium hypochlorite. Metal and disinfection byproduct (DBP) analyses were conducted by an independent laboratory.

Results

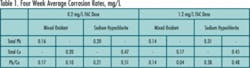

Analysis of the MOS-treated samples showed a lower concentration of copper and lead at both 0.2 mg/L and 1.2 mg/L concentrations. None of the weekly tests showed higher corrosion rates with MOS than with hypochlorite. Table 1 shows the four week average concentration of lead, copper, or lead/copper analysis while Table 2 shows the analysis after 4 weeks of exposure. In the case of lead, hypochlorite allowed up to five times greater the amount of leaching from the coupons than MOS.

Several disinfection byproducts were measured including HAA5s and TTHMs. In all cases, after four weeks the disinfection byproducts were greater in the samples dosed with hypochlorite. Of note is that dichloroacetic acid was 20% higher in samples treated with hypochlorite. Further, the residual measured as FAC was higher in the MOS-treated sample than in the sodium hypochlorite sample at the end of 4 weeks.

Conclusions

Jar tests followed by analysis via the EPA method 200.8 showed that water treated with mixed oxidants is less likely to leach lead and copper into solutions exposed to metal coupons than hypochlorite. Further, the water disinfected using the mixed oxidant solution showed lower TTHM and HAA5 than hypochlorite at the same concentration. Mixed oxidants also produced water that maintained a longer lasting, more durable chlorine residual than hypochlorite.

As a result of these pilot studies, the Rhode Island Department of Health, Office of Drinking Water Quality, is allowing C&E Engineering Partners and the Town of Westerly to conduct on-line studies of the entire water distribution system to determine MOS effectiveness.

The on-line pilot is expected to address the following parameters within the distribution system: 1) microbiological inactivation, 2) stability and longevity of the disinfectant residual 3) formation of disinfection by-products, and 4) impacts on lead and copper levels.

About the Authors:

Thomas B. Nicholson, P.E., is President/Chief Engineer C&E Engineering Partners. Paul Corina is Superintendent of Utilities at Westerly, RI. Susan B. Rivera, Ph.D., is a biochemist at Miox Corp., which provides on-site mixed oxidant and hypochlorite generation equipment.