Rehabilitating Gravity Filter Systems Using the Dual Parallel Lateral

Thomas M. Getting, John Geibel and Andrew Eades

The dual parallel lateral underdrain has been used in gravity filter systems for over 70 years. Its initial application was for water only backwash cleaning of granular filter media. But in the last 25 years the dual parallel lateral has been modified and applied with air/water backwash systems, a superior media cleaning method. Many filters that were installed with water only backwash systems have been rehabilitated using the dual parallel lateral underdrain with air/water scour.

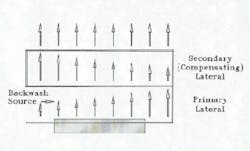

Most underdrain systems are considered "single pass" type systems. The single pass system has only one set of orifices controlling the flow of water and/or air similar to a straight pipe. This single row of control orifices provides an inherently weak distribution of backwash water with the orifices closest to the backwash source producing low flow rates due to the high flow velocity in the conduit. Because of this characteristic, lateral lengths are best kept to less than 10' overall. Air distribution is also limited.

The dual parallel lateral has two parallel conduits with two sets of metering orifices. Backwash water is introduced into and flows through the primary lateral, rises and discharges from the control orifices into the secondary compensating lateral. Any unbalanced flow from the primary lateral creates an opposing flow, forming a directly compensating velocity pressure gradient, which puts the secondary lateral into a near uniform hydraulic pressure condition throughout its length. This uniform pressure services the top deck dispersion orifices that discharge from the compensating lateral into the filter box.

The dual system of conduits provides such a uniform distribution of air and water that lateral lengths of up to 50' from the backwash source are possible.

Installation of the dual parallel lateral is simple. The filter compartment is constructed like a box with a rough-finished flat floor. The design does not require any special sub-structure such as supporting piers or beams, nor does it require added filter depth for a plenum or false floor. The lateral blocks are set in a base grout on the flat filter floor. The blocks are placed end-to-end in rows so the laterals are continuous through the length of each row. Rows of blocks are placed on 12-inch centers across the width of the filter. The spaces between the rows are filled with grout, locking the blocks together and making a flat and level floor that is an integral part of the filter box.

Air is introduced into the bottom of the dual parallel lateral through air header piping. Usually water is also introduced into the bottom of the lateral through a flume, a channel in the floor. Alternative arrangements allow the backwash water and air to be introduced into the end of the lateral through orifices.

Recent developments have improved the distribution of air and water in the dual parallel lateral. One of these is the addition of the water recovery channel and orifices in the top of the block. During air scour without the water recovery orifices, a zone of low pressure inside the secondary lateral causes water to flow down through some of the orifices. This flow imbalance is satisfied by the water recovery orifices which provide uniform air flow throughout the lateral. Another development is the baffle in the bell end of the secondary laterals, which ensures that the air and water that are metered into each four-foot section are discharged from that section. Without the baffle, the backwash water tends to push the air up and down the lateral, causing pulsations.

Many factors must be considered when rehabilitating an existing filter system. These include an adequate backwash flow based on the existing backwash system, configuration of the backwash flume, depth and shape of the filter box, and characteristics of the proposed media. The backwash flow rate and sometimes the backwash procedure are dependent on the type of media to be used.

The configuration of the flume is very important, as it is one of the major contributors of backwash water distribution in a filter along with the underdrain lateral type. The configuration of the filter box in filter rehabilitation will influence many decisions. It will determine the length of the dual parallel laterals, and the location of the backwash entry will determine the location and possibly the size of the flume.

Gravelless support plates can be used in lieu of graded gravel to provide added media depth or increased freeboard in an existing filter box. The use of a 3/4" gravelless plate adds 11" of either media or freeboard instead of using the customary 12" of graded gravel. The plates typically are made of high-density polyethylene beads that are sintered together. The pore space in the plate is similar to that of the barrier layer of gravel. Media, such as sand, anthracite, granular activated carbon, etc., can be placed directly on the surface of the plate.

Updating the instrumentation and control system is essential in maintaining an efficiently run filter system. The control system can be designed to keep a constant watch on process parameters to ensure optimum filtration. By continuously monitoring effluent water quality and filter conditions, the control system can automatically initiate the backwash sequence. This means that the filter is cleaned when it needs to be cleaned, as frequently or infrequently as changing conditions require and as long as necessary to clean the media. At the same time, automatic control of backwash eliminates the variations and accidents inherent in a manual backwashing.

Conclusion

The dual parallel lateral underdrain has been successfully used in thousands of new and rehabilitated water filter plant installations worldwide. The compensating secondary lateral has been shown to have superior backwash characteristics when compared to other types of single-pass underdrain systems. The closely spaced orifices of the dual parallel lateral provide better distribution of backwash air and water which provides better cleaning of the filter media.

About the authors:

Thomas M. Getting, P.E., DEE, is Filtration Product Manager at F.B. Leopold; John Geibel, P.E., is Chief Engineer at the company; and Andrew Eades is its European Sales Manager.