Fixed-Bed Nitrogen Removal Eliminates Need for Concentrate Handling

by Jess C. Brown

Nitrate is the most common groundwater contaminant in the United States. Due to its ability to reduce the oxygen carrying capacity of the blood (a condition called methoglobenemia or blue-baby syndrome), it has a primary drinking water standard of 10 mg/L NO3-N. Affected water treatment plants typically use ion exchange (IX) or reverse osmosis (RO) membranes to removal nitrate from their drinking water supply. While these approaches are effective at separating nitrate from the process stream, they both produce a high-strength, nitrate-laden waste stream that must be further treated or disposed, typically at a substantial cost.

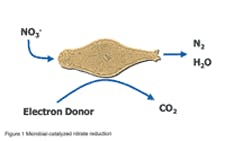

Biological processes offer an alternative to separation-based processes like IX and RO. Thermodynamic data show that nitrate is a strong oxidant (i.e., accepts electrons readily), which means that bacteria can gain substantial energy by mediating the transfer of electrons from an electron donor (e.g., acetic acid) to nitrate, thereby converting it to N2 gas and water. Biological nitrate treatment processes capitalize on this principle by maintaining an environment that fosters the growth of nitrate-reducing bacteria.

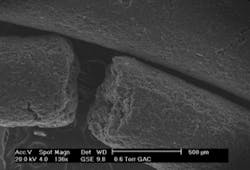

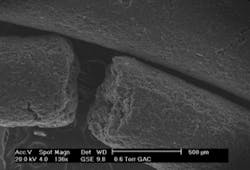

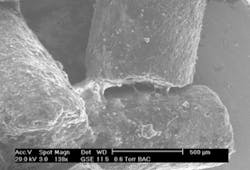

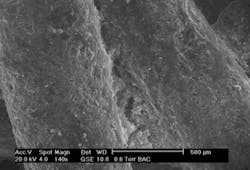

Carollo Engineers has developed a new fixed-bed (FXB) biological nitrate removal process that does not produce a concentrate stream. The FXB biological process uses a stationary bed of granular activated carbon (GAC) on which biofilms containing nitrate-reducing bacteria develop. Raw water is amended with an electron donor such as acetic acid, and then pumped across the GAC bed. Bacteria in the bed reduce nitrate to innocuous by-products.

A one-time acclimation period is required to develop sufficient nitrate-reducing activity. This is done by contacting virgin GAC with raw water and an electron donor for about one month. Typically bacteria indigenous to the local groundwater serve as the requisite microbial seed.

Pilot testing has shown that FXB biological nitrate treatment is efficient: 45 mg/L of nitrate can be eliminated at empty-bed contact times as low as 10 minutes (~3 gpm/ft2). To achieve this, approximately 14 mg/L of acetic acid-carbon would be dosed to the influent of the FXB bioreactor. The effluent biodegradable organic carbon concentration, which includes any residual acetic acid, is below the analytical detection limit (~0.1 mg/L as carbon). This is significant, as it indicates that product water from this process has very low regrowth potential.

Robustness testing has shown that process performance is negligibly impacted by fluctuations in raw nitrate concentration (step or gradual changes of 5-10 mg/L), backwashing events, periods of system shut-down (tested up to two weeks), and simulated acetic acid feed failures (up to 24 hours of no electron donor feed). As a result of this pilot testing performance, FXB biological processes have received approval from the California Department of Health Services for the removal of nitrate from drinking water in full-scale systems.

Design and operation of FXB bioreactors are comparable to the design and operation of conventional granular media filters. O&M costs can be as low as $0.15/1000 gallons ($50/AF) and water recoveries are typically greater than 97%. As an added benefit, a single FXB bioreactor can simultaneously destroy nitrate, perchlorate, tastes, odors, color, disinfection by-product precursors, regrowth potential, and chlorinated solvents.

Nitrate destruction eliminates the need for concentrate handling, making this technology sustainable. As residuals handling costs continue to increase, FXB bioreactors may become an increasingly important treatment option for utilities dealing with nitrate contamination.

About the Author:

Jess Brown, PhD, is the Carollo Engineers Research Group manager and one of the firm’s biological drinking water treatment experts. He has eight years’ experience in water and wastewater treatment specializing in treatment processes and applied research. Dr. Brown may be contacted via email at [email protected].