Decentralising power and water production with renewable energy

By Jürgen Rheinländer

Systems analysis software that can help private and public authorities quickly evaluate the feasibility of decentralised water and power projects and select appropriate technology and optimal design under specific site conditions has been developed by ZSW, (Zentrum für Sonnenenergie- und Wasserstoff-Forschung), the Centre for Solar Energy and Hydrogen Research in Stuttgart, Germany.

Many countries with water scarcity problems have constructed large-scale desalination plants with proven, cost-effective technologies for central seawater desalination at coastal sites or brackish water desalination near inland cities. However, remote towns and villages, far from the country's power and water grids, are technically neglected.

Typically, such settlements of a few hundred people with no clean groundwater depend on long-distance transport of water by truck, a risky source due to the limited availability of the driver, vehicle and fuel supply, and possibly unhygienic equipment. Authorities in charge of water supply do not often evaluate the real cost of this water supply method. Residents of these remote places deserve safe and cost-effective water and power, fundamentals of an acceptable standard of living.

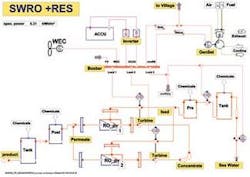

Water and power can be implemented on site by employing appropriate technologies and making the best use of local resources of energy, material and labour. This approach can be achieved through De-central Integrated Water and Power Points (IWPP) engineering, which is characterised by flexible design, fast implementation, energy efficiency, use of local (renewable) energy resources and low emissions. ZSW developed RESYSproDESAL, a systems analysis software that predicts technical, economic and ecological performance of desalination and water treatment (membrane and thermal processes), renewable energy sources (RES) for power (e.g. wind and photovoltaic (PV) power) and conventional power generation (e.g. diesel generator).

The range of desalination technologies comprises reverse osmosis (RO), electrodialysis, humidification/ de-humidification, mechanical and thermal vapour compression. The range of power generation technologies includes wind energy conversion (WEC), photovoltaic electricity generation (PV), solar thermal process heat, solar thermal power generation and all conventional power generation in hybrid combinations with renewable energy conversion.

Integration is the major challenge for the engineer of a decentralised water and power supply system. Usually the simultaneous water and power production and the hybrid use of conventional and renewable energy sources make reliable and cost-effective solutions feasible. Sustainable solutions in this context aim at —

• integration of water supply with power generation;

• integration of conventional with innovative and renewable energy sources;

• integration of main power source with back-up;

• integration of local labour and local (small) entrepreneurs into public private partnership (contracting) for operation and management of the IWPP;

• integration of local resources for material and energy;

• integration of technical and economic optimum with requirements for protection of local environment.

Systems analysis tool

System design and integration is done within the Process Simulation Environment IPSEpro from SimTech (Graz, Austria). The standard model library was completed with component models for water pre- and post-treatment, desalination processes, power conversion, distribution and recovery, water and energy storage.

Performance prediction for the designed integrated system is based on time series or histogram data in MS-Excel spreadsheets linked to IPSEpro via Visual Basic. Key results from evaluation are water quality and quantity, energy efficiency, RE fraction and avoided emission of CO2 for day, month or entire year.

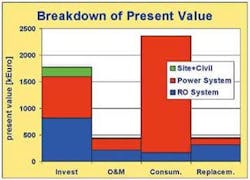

Economic and ecological analysis are included within performance spread sheets and yield all information required by investors: investment, operation and maintenance cost, replacement costs, present value of project, levelised electricity cost (LEC), levelised water cost (LWC), incremental cost for RE-integration, CO2-avoidance cost.

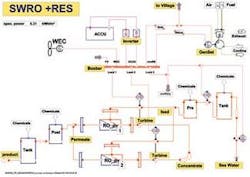

A recent project on the Mediterranean coast demonstrated the benefits from this comprehensive technical and economic system analysis. A containerised SWRO plant with 10m3/d-capacity for 250 people was designed to run on power from a 5-kW PV generator with 8-kW diesel back-up and 24-kWh battery storage. No energy recovery device was found for the small RO capacity and predicted specific energy consumption therefore was 6.8 kWh/m3. Nominal power for RO, auxiliaries and air conditioning of one container was 4 kW.

Performance and economic analysis resulted in g8/m3 LWC, 31% solar fraction and 7-kg/m3 specific CO2 emission. This LWC is not affordable for the population and the system would depend heavily on donors. Time series analysis revealed that the battery would never be used at full capacity as PV output would exceed the nominal 4-kW power demand for few hours per year only. Furthermore, the diesel engine was never run at more than 50% load resulting in an annual efficiency less than 20%.

The first obvious conclusion was to reduce capacities of battery bank to 2 kWh (the size used for smoothing out the fluctuation of PV power supply) and of diesel engine to 4 kW. This resulted in g7/m3 LWC and 5 kg/m3 specific CO2 emission, mainly from the better efficiency of diesel operation near nominal load. Still the high specific energy demand by RO was not satisfying. Searching the market for the smallest energy recovery devices led to a pressure exchange unit suitable for about 50 m3/d SWRO operation. Inspection of the site and surroundings revealed that a larger number of the population could be included into the water distribution system.

The plant was redesigned for 50-m3/d capacity for about 1,000 people and energy recovery by pressure exchange reduced specific energy to 3.6 kWh/m3. Nominal power for RO, auxiliaries and A/C now reached 8.5 kW. Still two 20-ft containers were sufficient for RO and diesel equipment and now served as supports for 80-m3 PV panels (equivalent to 8 kWpeak). Battery capacity was left at 2 kWh but again 8-kW nominal diesel engine capacity were set. This resulted in g2.7/m3 LWC and 2.5-kg/m3 specific CO2 emission. The solar fraction of power supplied to RO sank to less than 20%.

A population of 1,000 people will surely request more power supply to refrigerate food and medical supplies, air conditioning for a health station, communication and other needs. Diesel engine capacity could be increased by splitting into two units for securing permanent minimum capacity of water supply). This action could result in further reducing LEC and LWC.

This example of an optimised water and power production system demonstrated the following:

• systems analysis should include simultaneous technical and economic optimisation;

• integrated water and power supply is the more likely case and offers benefits from synergy and larger scale;

• the system with larger solar fraction is not necessarily the one with the lower specific pollution.

With support from the Middle East Desalination Research Center (MEDRC), the developers of the RESYSproDESAL started to prepare an expert system service to public and private authorities, expected to become accessible via internet end of 2005. The project shall support engineers, project developers and decision makers with procedures, tools and reference material for the quick evaluation of water and power point project feasibility, selection of appropriate technology and optimal design, all under specific site conditions and focussing on the opportunities for competitive application of renewable energy to desalination. This internet facility shall offer the user a catalogue of reference plant configurations, to which the user will be invited to enter via his web browser site data for climate, demand and economic boundary conditions. The user will obtain results from the technical, economic and ecological performance evaluation of the selected reference plant.

As a partner of ZSW and SimTech the project consortium includes the National Energy Research Centre (NERC) at Amman, which shall establish guidelines for site-oriented project development and contribute exemplary case studies based on actual rural water and power supply projects in Jordan. This activity shall become the start for a library available from the beginning of 2006 on the web site of MEDRC (www.medrc.org), containing a collection of exemplary systems analysis for specific projects in the Middle East and North Africa.

Author's NoteDr. Jürgen Rheinländer is a senior expert for Technical and Economic Systems Analysis in ZSW, the Centre for Solar Energy and Hydrogen Research, located in Stuttgart, Germany. For more information, contact the author at email: [email protected]