Listening for Leaks

By Mark Nicol

Known for their well-functioning drinking water distribution network, German water suppliers invest around €1.5 billion annually on infrastructure maintenance. Most utilities have a portion of aging pipes and unsustainable supply networks, as is the case with Netzgesellschaft Düsseldorf mbH (NGD). Faced with infrastructure reaching its end of life, it became critical for the utility to find a way to anticipate failures so they could prioritize maintenance and keep up with daily operations while managing the necessary capital expenditures.

NGD, a wholly owned subsidiary of Stadtwerke Düsseldorf AG, is responsible for network operation for the North Rhine-Westphalia capital of Düsseldorf in the area of energy and water supply. It provides the infrastructure for the distribution of electricity, gas, water and district heating to more than 600,000 residents, with a water pipe system that extends over 1,700 km.NGD identified a significant amount of transmission and distribution mains made of steel and cast iron that were installed between 1950 and 1965. These pipes were said to be strongly prone to corrosion. Due to the absence of historical data and limited capacity of underground work to assess its structural condition and remaining service life, NGD searched for a cost-effective solution to prioritize its pipeline rehabilitation and replacement decisions. The utility’s asset management team turned to Echologics® ePulse® condition assessment technology from Mueller Water Products.

“We chose the ePulse because of its ability to locate leaks non-invasively while assessing factual pipe condition versus theoretical [conditions],” NGD Asset Manager Markus Wall said.

NGD and Echologics field crews selected a 35 km section critical to the city’s supply network to kickstart the project. ePulse technology can assess the condition of distribution and transmission mains while simultaneously searching for leaks without the need for large excavations or service disruptions.

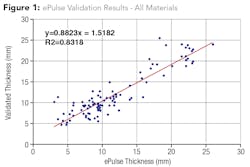

This is accomplished by attaching acoustic sensors to existing contact points, such as fire hydrants, valves or direct contact with a pipe. A sound wave is then induced in the pipeline and travels along the pipe. The acoustic sensors capture the time it takes the sound wave to travel between two sensor stations. The speed at which the sound wave travels is dictated by the condition of the pipe wall.As the sound wave travels, it pushes water molecules toward each other. Because water is incompressible, the molecules push outward on the pipe wall. This places a microscopic flex on the pipe wall — and the greater the flex, the weaker the pipe. Through this acoustic technology it’s possible to measure the actual strength of the pipe wall, which is an ideal measure of actual pipe condition.

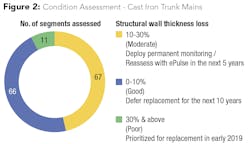

The results supported NGD’s cast iron replacement decisions by rapidly assessing the structural condition across the pipe network to prioritize areas with the worst degradation for immediate pipe replacement.

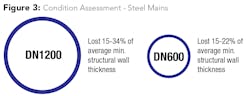

For the steel pipe sections, broadband electromagnetic measurements (BEM) were also used to characterize the pitting distribution on each section of pipe. Pipe measurements and other pipe condition datasets were then paired with a structural analysis to determine the condition of each pipe.Results

A 27.7 km section of cast iron trunk main was assessed using ePulse technology with three leaks successfully pinpointed. Figure 2 provides a summary of decisions made by NGD based on the data.

ePulse technology was also used to assess 900 m of DN600 and 500 m of DN1200 steel mains. Below is a summary of findings (see Fig. 3). The minimal average remaining structural wall thickness calculation aligned with the pitting distribution and the minimal wall thickness values gathered through the BEM measurements provided a useful dataset for NGD to make informed replacement decisions.Netzgesellschaft Düsseldorf mBH plans to remeasure the moderate pipes with ePulse technology after five years to evaluate the change in structural remaining wall thickness. WW

About the Author: Mark Nicol is senior director of sales and operations for the international division of Echologics for Mueller Water Products. He has over 15 years of experience in the water industry.