Reservoir Renovation Requires Top-Down Refurbishment

The Marine Corps Air Station at Camp Pendleton, situated on 125,000 acres just north of Carlsbad in Southern California, was established in 1942 as the primary United States Marine Corps training facility on the West Coast. With a steady population of nearly 100,000 living on the base at any given time, the services and infrastructure put into place over the years were as significant as a typical large town. Part of the base’s expansive infrastructure included two water reservoirs — one of them 0.5- and the other 1-million gallon (MG) structures — built in the 1950s to provide potable water to base inhabitants.

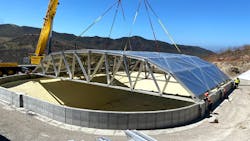

Over the years, as the facility aged and the reservoirs approached the end of their useful lives, Marine personnel realized that both reservoirs needed to be completely refurbished. The refurbishment needed to seal and reline the concrete basins, replace the existing roof structures, repair some pipes, and provide upgrade work for the vault.

Since the reservoirs were the primary source of water for the active base, one of the key requirements of the project was the need for a quick return to service — to have the structures out of commission for as short a time as possible. Luckily for the base, since there were two reservoirs, they could get by with just one while the other was shut down for repairs. But expediting the work was still going to be a significant component of the project.

When considering options for the refurbishment, Camp Pendleton Water Resources Division engineers had to first choose a contractor to oversee and execute the project. After issuing a request for proposal and reviewing bids from several companies, Central Environmental Inc. (CEI) — a full-service, general construction, demolition, and environmental company based in Anchorage, Alaska — was commissioned for the project.

Once the contractor was chosen and the scope of work was identified, the team had to determine the ideal option for sealing the concrete basins. They considered a number of different coatings and lining solutions.

The team mapped out the timeframe and logistics for executing the work and determined that the 0.5-MG reservoir would be the first one to be addressed during the summer of 2021. It was determined that a lining solution couldn’t be accurately measured until the water was drained from the reservoir and the old roof was removed to facilitate a true assessment of tank size and lining requirements. Given the logistics and length of time needed to perform the assessment, measurement, manufacturing, and installation of a lining system, the team determined that a lining solution would not meet the project’s quick return to service requirement.

Since the lining solution was ruled out as a viable option, the team explored various coatings solutions, many of which could be easily applied directly to the substrate and can be specified without having to drain the reservoirs or remove the roofing. The product chosen was PPG RAVEN AquataFlex® 505, an epoxy polyurethane coating by PPG© and RAVEN© Lining Systems, due to the fast cure times of the polyurethane with the increased chemical resistance of an epoxy. The 100 percent solids, USDA-Certified Biobased product is an environmentally friendly, surface tolerant, zero V.O.C. solution; providing ease of application, a decent pot life, and high elongation.

A Complex Process, Step by Step

The first step in the process for the CEI team was to drain the reservoir, allowing them to prep the surface of the concrete for the applicators. The entire basin was sandblasted, removing any loose material and imperfections, and exposing compromised areas of the concrete that needed to be repaired or patched. Mechanical grinding prepared the transition areas and edges, and earthquake splash protection was also put in place.

The proximity of the reservoir’s location to the Pacific Ocean and the moisture coming off the water, combined with the warmth of the southern California sun, provided application challenges that had to be addressed in real-time.

Polyurethanes struggle with exposure to high humidity environments of any kind. Ambient temperature ranges also had to be considered, as surface temperature of the concrete couldn’t get too warm in order to optimize pot life. Along with the help of a third-party monitoring company, the CEI team was able to identify a couple of application windows over the course of a 24-hour period that struck a balance between low moisture and moderate temperatures to get the job done in a timely manner. Pre-dawn mobilizations, midday work stoppages, and resuming late afternoon and working well into the night before the moisture came in off the water — with actual start/stop times determined by real-time temperature and relative humidity readings — were the scheduling patterns that enabled the team to work effectively and still meet timing deadlines.

As the team finalized the first reservoir job and began to plan out the execution of the second, they took what they learned and put some changes into place to make the job more efficient. Key among these changes was to tent the second reservoir with plastic at the beginning of the project, which protected the roof above from overspray and minimized exposure to the elements.

With the first reservoir, having full exposure to the moisture off the ocean and to the hot California sun necessitated starts and stops with the mobilization of the applicators, requiring workers to work within specific windows of time over the course of a day. With the second reservoir, the tented plastic minimized relative humidity and extreme fluctuations of temperature, providing for more stable surface temperature of the concrete and enabling less work stoppages during the application process. The tenting also protected the roof above from overspray, and provided lower concrete surface temperatures, enabling the applicators to immediately address outgassing and pin-holing — a common issue with the application of a 100 percent solids epoxy like the Raven 505.

Another adjustment made by the team based on their experience with the first reservoir project was to change the plural spray equipment from a Graco XP70-hf to an XP50-hf. This allowed the applicators more control of the material as it came out of the gun and was applied to the concrete substrate. The equipment change also reduced the amount of maintenance and parts replacement over the course of the job, saving the team valuable time in the process.

Continuous Improvement

Like any other organization with a physical plant, water and wastewater utilities continually assess their infrastructure needs for short- and long-term planning. And as facilities and structures reach the end of their useful life, the planning is critical for keeping the plant up and running, for project scheduling, and for identifying the capital expenditures necessary to make it happen.

As the team at Camp Pendleton recognized with their two reservoir refurbishment projects, it is important to obtain a comprehensive understanding of the problem, take a realistic look at possible solutions, and identify a contractor with the expertise to execute the project with a product solution that will address the needs of the facility well into the future. WW

Published in WaterWorld magazine, September 2022.

About the Author

Randy Gonzalez

Randy Gonzalez is the West Region Business Development Manager for PPG PMC Raven Lining Systems. He can be reached at (760) 685-7784, or at [email protected].