Water System Standardizes on Clamp-On Ultrasonic Flowmeters

By Daryl Belock and Phil McDonald

Engineers and technicians at San Antonio Water System (SAWS) first became interested in ultrasonic flowmeters in 1995. Initially, SAWS wanted portable meters to use as survey tools in the field to check pump outputs, verify in-line flowmeters, and for flow surveys where no existing flowmeters were installed.

SAWS considered several portable ultrasonic flowmeters while looking for a meter technology that would be easy to use yet flexible enough to handle a wide range of pipe materials and pipe sizes. Based on their evaluation, non-intrusive, clamp-on ultrasonic flowmeter technology based on the transit-time principal was chosen.

One of the first applications in which the portable flowmeter was extensively used was checking pump outputs at several well locations to verify run-time/pump capacity data that SAWS had collected over the years and to verify that the well pumps were functioning properly.

Some water stations had five or more pumps feeding a main line. Pressure transmitters were used to determine that the station was pumping enough water to fill the outgoing main lines. Curiously, some pumps ran all the time with little increase in downstream pressure. Using the PT868 flowmeter from Panametrics, technicians were able to measure the flow rates within the individual feeder lines downstream of each pump to check flow. In many cases, flow rates were considerably lower than expected based on the pump curves for the particular pump.

When that happened, the lines were shut down and the pumps inspected. They were found to have badly damaged impellers. The motors were running all the time because the control system was calling for more pressure. However, the pump could not supply flow to increase the pressure due to the damaged impellers. The damaged pumps were repaired and pump run time was significantly reduced. The cost savings in electricity alone exceeded the capital cost of the portable flowmeter.

According to Dale Collins, a 15-year veteran technician with SAWS, "the portable flowmeter gets used as much or more than any other piece of portable diagnostic equipment that we have."

The flowmeters have been so successful at diagnosing flow problems that the SAWS water department often gets calls from the wastewater department to do flow surveys for facilities such as lift stations.

New Aquifer Regulations Require Flow Measurements

In February 1999, the board of the Edwards Aquifer Authority approved rules that forced the San Antonio Water System to install flow meters on all it's water wells by year's end. The new rules were approved in light of ever growing needs to monitor the Edwards Aquifer.

SAWS is the aquifer's largest pumper and controls 80-85 percent of the municipal water flow in the greater San Antonio area. SAWS had flowmeters installed on only a portion of its existing 85 wells. Flow from the remaining wells was estimated by analyzing pump curves from the pumps used to pull water from the wells. This method was viewed as "questionable," in terms of accuracy, in the minds of several board members of the Edwards Aquifer Authority.

Most of the well pumps are centrifugal type. The amount of flow they produce depends upon the differential pressure in the well compared to the pressure downstream of the pump - something that can change with time.

SAWS had conducted "Run-Time" analysis on the pumps periodically. The time versus the capacity determined from the pump curve gave the total flow the pump had pulled from the well. The Edwards Aquifer Authority regulations called for metering accuracy to be better than +/-5 percent, an accuracy that could not be stated outright without meters on existing, un-metered wells.

Engineers and managers at SAWS began to look for metering methods that could meet several criteria. First, the meter would have meet or exceed the +/-5 percent accuracy requirement. Secondly, the meters would have to be installed on existing exposed piping at the wells. The ease of installation into existing piping systems would be an important consideration. In addition, the meter would have to supply a 4-20 mA signal, which would eventually be tied into a planned SCADA system.

Clamp-on transit-time ultrasonic flowmeters were considered for these permanent installations based on the experience SAWS had with its portable flowmeters.

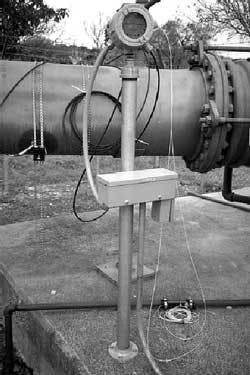

For these permanent installations, SAWS wanted an electronics package that could be installed outdoors and hold up to both heavy rain and the ambient temperature extremes found in the San Antonio area. A Panametrics XMT868 transit-time ultrasonic flowmeter was chosen. This meter is housed in a NEMA 4 enclosure and could be field mounted. In addition, the unit can be configured with an optional display to indicate local flow or diagnostic information. This is helpful in installations where the meter may be periodically monitored directly by looking at the meter.

The meter can be configured either as a one-channel or two-channel instrument. In a two-channel configuration, the meter can be installed with two different sets of transducers, thereby reducing the price per point of installation. In addition, the flowmeter can calculate the individual flow rate for each pipe and calculate the net differential flow rate.

The XMT868 has no local keypad, but can be configured via a PC with Panametrics' Instrument Data Manager (IDM) software. The IDM software has a menu-driven interface that allows a user to set up site configuration data. Site data can also be stored as a file on the PC. If a particular transmitter develops any type of service problem, a spare transmitter can be set up by simply loading the site parameters archived on the PC and swapping it into service.

Field Installations

All initial installations of the flowmeters were on wells spread through the SAWS network. These wells actually have two flow lines to measure. The first line is the primary output from the pump. These lines run from 10 inches to 16 inches and are almost always carbon steel. However, there is also a smaller "pre-lube" line which runs back down into the well from a tap off the main header. The pre-lube water flow is used to lubricate the pump shaft during operation. The net flow out of the well is the flow on the main header minus the pre-lube flow. Pre-lube flows are expected to be 70-80 gpm, but some well sites measured pre-lube flows of 215-300 gpm - not an insignificant amount of water!

SAWS Experience

To date, SAWS has well over 100 XMT868 installations. Application experience includes monitoring flow in 1/4 inch copper, 2-3 inch PVC, 1-36 inch carbon steel and 4-30 inch cast and ductile iron. Typical flow applications include monitoring wells, pre-lube lines, recycle water lines, distribution flow for new residential sub-divisions and pump stations.

Rangeability is a big issue, especially on the larger pipe sizes where the ultrasonic flowmeter can read very low, almost no flow conditions as well as very high, full-on flow rates. With a rangeability of 400:1, a single clamp-on ultrasonic flowmeter installation can handle the job.

Today, only about 15 of the XMT868 installations are tied into the SCADA system. These are on high service primary pumps. However, SAWS has plans to tie in more of the meters into the SCADA system depending upon the importance of the measurement point to overall control and/or reporting requirements.

When asked about maintenance with the ultrasonic flowmeters, the technicians at SAWS responded that, "overall, we've had good success."

Some issues do come up periodically. For one, the acoustic couplant or "grease," which is a silicone-based gel applied to the transducer face to ensure sufficient acoustic coupling of the transducer face to the outside pipe wall, may need replacement every one to three years to ensure good signal strengths. There have also been periodic electronics issues. However, SAWS maintains a couple of spare transmitters in stock for this contingency. Faulty electronics modules are repaired in the shop or sent back to Panametrics for testing and repair.

SAWS prefers clamp-on transit-time flowmeters over other technologies and uses it for a majority of its flow measurement needs. Since the same technology is used over and over again, technicians have a high level of experience and are comfortable with the technology.

About the Authors:

Daryl Belock is Assistant Marketing Manager for Panametrics PCI Division in Waltham, MA. He has a BSME from the University of Vermont and a MBA from Babson College in Boston. He has 10 years of applications, sales, and marketing experience with Panametrics.

Phil McDonald has a BA from Trinity University in San Antonio and is a Systems Analyst with 15 years experience in Controls and Instrumentation at San Antonio Water System.