Pipeline Zooming: A Simple Process for Condition Assessment

Time, budget and resources often keep a municipality from maintaining comprehensive, up-to-date information on the condition of pipeline infrastructure. Without a complete understanding of infrastructure condition, a municipal supervisor cannot properly prioritize and schedule maintenance activities. As a result, backups, collapses, and overflows happen unexpectedly, and must be dealt with on a triage basis at great expense.

Increasingly, municipal supervisors are turning to zooming, a pipeline inspection technique using a zoom camera lowered into a pipeline to assess and record conditions within range of the camera. Zooming’s goal is to rapidly classify infrastructure as either satisfactory or in need of maintenance, mapping, rehab, or additional CCTV inspection. These classifications allow a supervisor to prioritize maintenance activities, committing maintenance resources - inspection crawlers, cleaning trucks, cutters/rodders, GPS surveyors, and grouting and relining crews - exactly where they’re needed most.

Zooming complements other inspection techniques, it doesn’t replace them. Inspection crawlers can’t be matched for their detailed, 360-degree inspection of pipe, but they move slowly, require substantial investment, and demand considerable manpower and overhead. By contrast, a single operator equipped with a zoom inspection camera can make a rapid visual assessment of pipe segments, identifying satisfactory regions of pipe and problem areas where detailed crawler inspection or other action must be taken.

A typical zoom inspection system consists of a camera, lamps, a positioning pole and a video display. Grasping the pole, an operator at street level lowers the camera into a manhole and orients it to look down an adjoining pipe. Starting with a wide-angle view, the operator slowly increases zoom so the camera’s view advances down the pipe. In this manner, an operator inspects the entire length of visible pipe for anomalies, and then classifies its condition accordingly.

Because high-magnification viewing presents special challenges, successful zooming demands purpose-built equipment. The higher the zoom ratio, the farther the camera can view with acceptable detail. However, distant viewing requires bright illumination and camera stability. Identifying a suitable zoom inspection camera means evaluating its components in light of these considerations, while also paying attention to portability and ease of use.

A camera’s optical zoom indicates its power to magnify and, correspondingly, how far it can view down a pipe. Optical zoom is achieved with lenses, so no clarity is lost. Digital zoom, on the other hand, simply enlarges pixels, so quality degrades as the view advances onscreen. A state-of-the-art zoom inspection camera typically employs 18:1 optical zoom, which together with a digital zoom of 12:1 would yield an overall zoom spec of 216:1.

Illumination typically constrains the effective viewing distance of a zoom inspection camera in pipe and other unlit areas. Nevertheless, many systems can see as far as 250 feet (depending on pipe diameter) using focused HID lighting. Compared to incandescent lamps, HID arc lamps generate exceptional lumen output with only modest battery drain, and penetrate deep into pipe when properly focused to a beam of approximately 6 degrees. Electronic gain and shutter speed control can also improve visibility in low-light situations.

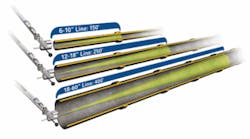

Intense illumination means little unless the beams are properly centered within the pipeline, and successful inspection also requires a stable view. A good targeting device answers both needs. A targeting device with an adjustable, graduated standoff will center the camera view in a wide variety of pipe sizes, ensuring even illumination of the pipe wall. Spring-dampened designs also allow minor in-situ height adjustment, as well as help attenuate picture wobble at high magnification.

One core concept of zooming is ease-of-use, so portability is important. The largest portion of a zoom inspection camera is its collapsible pole. A high ratio between extended and collapsed lengths determines how easy a pole is to stow. Pole material affects strength, weight and rigidity. Plastic poles are common, but aluminum poles offer better strength per weight. Carbon fiber is optimum, weighing very little while maintaining the rigidity needed for stable viewing.

Typically, an operator’s hands are occupied with the pole and zoom controls, so productivity can be improved with a belt or vest that holds the control interface, battery, viewer/recorder and accessories. Operator fatigue and battery life determine how much gets inspected in a shift, so a control vest needs to distribute the weight of the system components evenly, and a lightweight, long-lasting battery technology like nickel metal hydride (NiMH) is essential.

Aside from these basic considerations, other features are available to extend the capability of zoom inspection. Distance measurement, which displays the distance to an in-focus target onscreen, is ideal for determining the location of a pipe tap, blockage or collapse. Integration with GIS and inspection documentation software programs makes it easy to correlate inspection footage to maps and written notes, allowing annotation, archiving and retrieval.

A zoom inspection camera is optimized for the task of pipeline zooming, but the technology is versatile enough to serve other areas of infrastructure maintenance, as well. In an emergency situation, they can be used to identify the origin of a backup or overflow, or to pinpoint a collapse.

Manhole inspection is an integral part of infrastructure assessment, and some zoom cameras can be adapted for wide-angle viewing. A wide field of view allows a camera to see larger regions of a manhole wall or other up-close target. It also allows an operator to capture the entire circumference of a manhole wall from a downward-looking vantage point. Commonly, use of a wide-angle lens requires a lamp diffuser for even illumination.

Cleaning crews can use cameras to examine a line before cleaning, and then again afterward to judge the effectiveness of cleaning. To monitor the efficacy of a specific cutter or nozzle, a technician can view its performance in real time from a downstream manhole. In the contractor market, where profitability demands that service jobs be quoted accurately, a zoom inspection camera also can help a bidder assess the scope of work in advance.

About the Author:

Richard Lindner is President of Envirosight, LLC, based in Randolph, NJ. The company specializes in video pipeline inspection. Its QuickView zoom inspection camera carries several zooming patents and patents pending. The company also manufactures video inspection crawlers. More information on the company and its products can be found at www.envirosight.com