Pipe Lining Project Saves Money, Environment

The city of Boulder, CO, is served by two high-pressure water mains which cascade down to the city through narrow canyons from high mountain reservoirs. The newest main is a 30-year-old 30-inch steel pipeline, while the other line is of mixed materials and the oldest sections probably were laid about 1917.

Early records for the oldest line no longer exist, but the line starts as a 24 inch steel pipe about two miles west of the city, at the Boulder Filtration Plant. The pipe is buried shallowly in an abandoned railroad right-of-way which has been converted to a bike trail. The pipeline shares a narrow canyon with Boulder Creek and State Highway 119 and they all zig-zag down the mountain to Boulder. After 2,300 feet, the 24 inch pipe splits into two 16 inch lines which continue for 7,100 feet into the city. One of the 16 inch lines is made of steel and is in good shape, but the other 16 inch line was made of cast iron and is in very poor condition.

Randy Earley, Utilities Project Management Group, City of Boulder, explained that the city had taken the old main off line because the 16 inch cast iron pipe had some leaks which developed recently when the pipe froze. However, the city wanted to repair or replace the damaged 16 inch pipe and maintain the line for redundancy, if the cost was not prohibitive.

Investigating Alternatives

Earley's group hired McLaughlin Water Engineers, Denver, CO, to develop rehabilitation or replacement alternatives for the city's evaluation. Two criteria were key - the solution had to be able to withstand a test pressure of 225 psi while spanning a half-inch gap, and it had to maintain the current flow capacity.

McLaughlin Water Engineers' Vice President Bill Kendall explained that after a thorough investigation, his company narrowed the possibilities to total replacement with a new pipe, a cured-in-place liner, or a tight-fitting, high-density polyethylene (HDPE) liner. An open-cut replacement was rejected because it was prohibitively expensive, and too environmentally damaging and disruptive. Also, current regulations required deeper burial for new pipelines than the existing main, so rock blasting would be required.

The McLaughlin engineers were concerned about using the liners because neither was designed to withstand the required pressure. Both technologies would have to rely upon the host pipe for support. As a result, representative samples of the pipe were inspected carefully and coupons from the pipe were tested for strength. After an exhaustive study, the technologies were approved and the project was put out for bid. The winning bid was submitted by ARB Inc., Lake Forest, CA, a licensee of the Swagelining process.

Lining Process

The Swagelining process uses polyethylene (PE) pipe which has an outside diameter slightly larger than the inside diameter of the pipe to be lined. During the installation process, the PE pipe is pulled through a die to temporarily reduce its outside diameter. This reduction allows the PE to be pulled through the host pipe. When the pulling force has been disconnected, the PE pipe begins to return to its original diameter. As the pipe relaxes, it presses tightly against the inside of the host pipe, eliminating all annular space.

In this case, the liner was 16 inch (outside diameter) HDPE with a wall thickness of 1/2 inch. The pipe, which came in 50 foot lengths which were fused together on site, had a DR 32.5 rating.

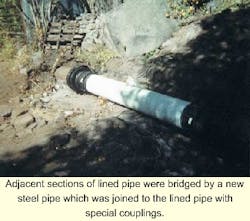

Short sections of the dual main were excavated and removed at convenient locations along the pipeline to create entry and exit points during installation. Normally, the Swagelining process can install up to 1,500 feet of HDPE in a single pull, but when the 16 inch main had been installed, most of the joints had been deflected to help the pipeline follow the contour of the canyon. As a result of the many bends, the pull lengths were reduced. After adjacent sections of pipe had been lined, they were bridged by a new steel pipe which was joined to the lined pipe with a special coupling.

The Result

The bike path never closed, and traffic on the state highway never was interrupted, even though shorter pulls had to be made than originally anticipated. The project was completed in mid-October before high water in the creek created problems for the workers. And, there is no longer any concern that the old cast iron pipe might fail.

"Swagelining was the least expensive alternative, and it worked for us," Earley said. "I'm not sure we could have gotten timely approvals from the state and county to do open-cut replacement, even if it had been affordable. It would have been much more destructive."