Trenchless Water Main Rehabilitation Design Considerations

By V. Firat Sever

According to a 2005 study submitted to the United States Congress, $183.6 billion needs to be invested by 2023 into distribution and transmission infrastructure (pipelines) just to continue to provide clean and safe drinking water to consumers. This represents 70% of the total investment needed ($263.9 billion) for the drinking water infrastructure in the U.S. Of this total, $120 billion was considered a current need to provide adequate protection of public health. Because only a fraction of this investment is occurring, a greater burden will eventually be placed on future utility customers.

Trenchless water main rehabilitation provides a viable alternative to utilities versus replacement and can be often implemented at a significantly lower economic and social cost. Lining systems can help renovate virtually any type of pressure pipe, including concrete, clay, iron, steel, and PVC.

Techniques and materials include cement mortar lining, slip-lining (fold and form, deformed/reformed, or direct insertion), cured-in-place pipe (CIPP), and (more recently) spray-on polymeric liners. Performance of the materials used for this type of application has been studied over the years and various publications on the issue are available.

There are four main reasons to rehabilitate deteriorated water mains: (1) to preserve/enhance water quality, (2) to prevent structural failure, (3) to prevent water loss, and (4) to improve hydraulic capacity.

Water Quality

Deteriorated water mains degrade water quality as a result of increased turbidity, resulting in taste and odor complaints by consumers. Water quality degradation is particularly a concern for cast iron pipes, of which installation dates back to 19th century in the developed countries.

Present experience indicates that conveyed water quality can be improved by relining deteriorated pipelines. This is particularly true if polymeric materials are used for rehabilitation. These achieve the highest water quality by creating an inhospitable environment for biofilm growth thanks to the smoother surface and lower reactivity of plastic.

Structural Integrity

There are two primary reasons for a water main to break under external and internal loads. The first and most common one is circumferential stress and cracking due to bending as a beam. Soil movement generates voids in pipe bedding, causing a pipe segment to act as a beam across the void and bend due to the pipe's own weight and overburden and lateral soil pressure. This bending results in separation at joints and circumferential cracking depending on the conditions of joints or pipe material.

The other main reason for structural failure is hoop stress resulting from internal pressure. Hoop stress failure will appear as longitudinal cracking and is more common among plastic pipes which are made of more flexible materials.

Structural integrity of a deteriorated water main can be completely restored by rehabilitating with a fully structural liner (AWWA Class 4). Using semi-structural liners (AWWA Class 2 or 3) might be a viable alternative for water mains that have considerable residual strength. In this case the lining will partially depend on the residual stiffness of the host pipe, and depending on the level of adherence, can act as a composite system.

Water Loss

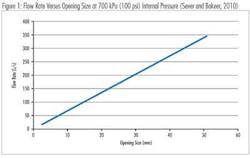

Water loss is another major impact of deteriorated water mains. Losing treated water throughout the distribution system has both economic and political consequences. It is estimated that 6 billion gallons of treated water leaks out of water lines every day in North America. Leaks through cracks, loose joints, and gaps along deteriorated water mains can be completely eliminated by relining them. Nevertheless, gap size along a water main subject to rehabilitation should be carefully analyzed prior to selecting a method.

Hydraulic Capacity

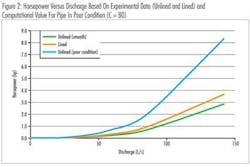

Water main rehabilitation with a smooth liner increases the Hazen-Williams roughness coefficient (C) of a deteriorated pipe and can help improve hydraulic capacity. Nevertheless, internal diameter of the host pipe is reduced by the liner installation. Overall capacity improvement after rehabilitating an old water main depends on the condition of the pipe prior to rehabilitation and thickness of the liner. This was analyzed with full scale tests (Barber et al., 2004) and a graph associated with this article compares the hydraulic capacity or pumping power needed for smooth/unlined, relined, and deteriorated unlined pipe (Sever et al., 2006).

Using a thick liner may also significantly contribute to manufacturing and operating costs. The total mass of the liner used will be higher for a thicker liner than that of a thinner material. Therefore, ideal liners should be designed to have satisfactory resistance against mechanical and chemical effects with minimal thickness.

Lining Materials and Methods

Trenchless water main rehabilitation is an emerging field and new techniques and materials are continually being developed. Water main linings can be structural, semi-structural, or nonstructural. AWWA Manual M28 – Rehabilitation of Water Mains identifies four types of linings with respect to their structural capabilities:

Class I Linings: Essentially nonstructural in nature, these linings are used to restore water quality in water mains that are structurally sound, but suffer from corrosion and tuberculation. Class I linings might be an economic and easy-to-install option for rehabilitation projects that are aimed at improving water quality and, for some cases, hydraulic capacity by increasing the Hazen-Williams coefficient. They do not provide a viable solution if there are apparent holes and gaps in the host pipe or structural support is sought. Examples include thin-wall polymeric (epoxy and polyurethane) and cement mortar linings.

Class II and III Linings: These types of linings are considered semi-structural, and designed to give structural support in addition to improving water quality and hydraulic capacity. However, hydraulic capacity improvement is dependent on initial condition of the host pipe and lining thickness. Class III linings have adequate ring stiffness to withstand external loads by themselves; however, they are not designed to withstand the maximum allowable operating pressure (MAOP). High-build polymeric, spray-applied linings (e.g., epoxies, polyurethanes, polyureas) and thin-walled extruded linings (medium density polyethylene installed by swage lining, die lining, etc.) are examples of Class II and III linings.

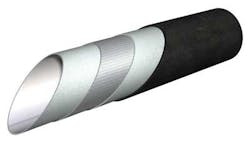

Class IV Linings: A Class IV lining is essentially a pipe within a pipe. They are designed to withstand MAOP for the design life of rehabilitation (typically 50 years). Class IV linings will work as a replacement pipe in case the host pipe fails and may provide a more economical and easier to install option in comparison with conventional replacement (open-cut) or pipe bursting. The downside of fully-structural linings is that they are thicker than semi-structural or nonstructural linings, which means a smaller internal diameter (ID) for the rehabilitated pipeline and, depending on the lining type, restoring service connections may require excavation. Polymeric linings (typically high density polyethylene or PVC) installed by slip-lining and cured-in-place pipe linings are examples of Class IV linings.

About the Author: Firat Sever is a Senior Engineer with Benton & Associates Inc., based in Illinois. He has more than 10 years of experience in the water and wastewater industry. Sever's doctoral dissertation was based on the use of polymeric linings for pipeline rehabilitation. He may be contacted via email at [email protected].