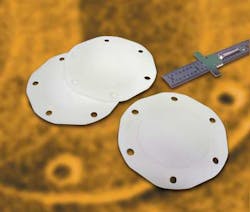

Custom diaphragms

By converting the thermoset fabric-reinforced rubber diaphragm to functionally-improved co-polyester, Minnesota Rubber and Plastics eliminated the possibility of pinhole leaks between fabric weave caused by rubber tear and de-lamination. Subjected to and proven by 300 PSI burst test pressure, these injection molded parts also deliver flex-life and chemical resistance while adding cost reduction opportunities. Measuring 2-1/2" diameter x 1/32" thickness with six equally-spaced 1/16" mounting holes, these TPE diaphragms can be created in virtually any custom size/configuration to meet customer requirements. The chosen material offers the tensile strength to replace the fabric in this application, while component geometry has been modified to accommodate differences in the material's stiffness.

Minnesota Rubber and Plastics

www.mnrubber.com