Singapore’s DTSS phase 2 to include fibre optic cables for remote monitoring

SINGAPORE – Construction works have started on the enhanced conveyance system of the Deep Tunnel Sewerage System (DTSS) Phase 2 in Singapore.

Advanced technologies will be incorporated so that the project is engineered for an operational life expectancy of 100 years.

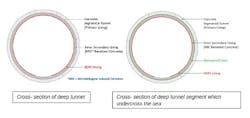

The deep tunnels will be lined for corrosion protection – especially against microbiologically-influenced corrosion, with an additional water-tight membrane coating the tunnel section running undersea.

Advanced maintenance features of the deep tunnels include the use of embedded fibre optics for remote sensing and monitoring of structural integrity. The fibre optic cables will be cast into the concrete primary lining around the deep tunnel to enable remote monitoring of the long term structural integrity of the tunnel.

National water agency PUB said this is “critical when other construction works are underway in the vicinity, or during other events such as seismic activity”.

The deep tunnels will also be the first project in Singapore to use air jumpers (AJs) in the operations of its air flow management system to minimise the number of Odour Control Facilities (OCFs) as part of Air Flow Management.

AJs are installed at ground level along the tunnel length to manage air flow within the tunnel. The AJs help to push odorous air rising from the deep tunnel back down, where it flows to the OCFs downstream, located away from residential areas. The odourous air is then treated before being released.

The deep tunnels in Phase 2 will connect to the existing deep tunnels in Phase 1 serving the eastern part of Singapore and the public sewer network to create one seamless integrated system.

The whole of Singapore will be served by the DTSS when Phase 2 is complete by 2025. Used water will be conveyed from the DTSS via gravity to three centralised water reclamation plants for treatment, before it undergoes further purification to produce NEWater, or discharged into the sea.

To be built using the tunnelling method, this massive 100km used water conveyance network for DTSS Phase 2 will run largely under the Ayer Rajah Expressway (AYE), crossing undersea at Tuas Bay and ending at deep inlet shafts within the future Tuas Water Reclamation Plant.

A total of 19 Tunnel Boring Machines will be used to dig at depths of between 35 metres to 55 metres below ground and under the sea to create 40km of deep tunnels and 10km of link sewers. The remaining 50km of link sewers will be constructed using a micro-tunnelling method known as pipe jacking.

Singapore’s national water agency, held a groundbreaking ceremony for the enhanced conveyance system of the to mark the start of construction works. Officiated by Guest of Honour, Minister for the Environment and Water Resources, Mr Masagos Zulkifli, the ceremony was held at the site of DTSS Phase 2’s first tunnelling shaft at Penjuru Rd.

Yong Wei Hin, director of DTSS Phase 2, PUB, said: “The construction of the conveyance system for DTSS Phase 2 will pose a new set of exciting challenges for us, as we look forward to dig deep to navigate through a variety of ground conditions in the Jurong Formation as well as tunnel beneath existing underground infrastructure and even under the sea.”

###

Read more

Singapore plans for 55% water recycling with DTSS pre-qualification