Innovative Construction Project Cuts Capital Costs

By John Murphy, James Ring and James Seiler

The city of Bangor, Maine, used pre-cast concrete panels to speed construction of a 1.2 million gallon in-ground storage facility to help control combined sewer overflow (CSO) discharges from the Davis Brook drainage area. In the end the project cost the city significantly less than originally expected.

The City of Bangor has been working on a multi-million dollar program to control CSOs since 1987. In 1992, a CSO Control Plan was prepared. The plan identified the most cost effective and water quality effective projects to control CSO discharges. To date the city has expended in excess of $25 million in mostly local funds. Ten of the original 22 CSO locations have been eliminated and CSO activity has been reduced by approximately 50 percent. Projects are scheduled through 2009 and capital expenditures are expected to total in excess of $50 million.

To control CSO discharges in the Davis Brook drainage area of Bangor, the CSO Control Plan originally recommended the construction of a storage tank that was 150 feet long by 70 feet wide and 16 feet high, buried deep underground. Planners initially estimated the cost of such a tank at $3.9 million, but as planning progressed estimates climbed to nearly $7 million.

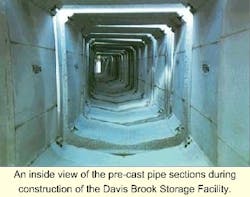

After reconsidering the project, and acquiring a 30-acre switching yard from the Maine Central Railroad, the city decided to construct the facility in the yard next to the existing 42-inch Penobscot interceptor. To help keep costs down, the city decided to build a tunnel facility 2,400 feet long, nine feet high and eight feet wide out of pre-cast concrete sections.

The new concept also addressed the issues associated with deep excavation. With a maximum excavation depth calculated at around 13 feet, shoring could be accomplished by trench box. There would be no need for expensive sheet piling, slurry trench construction or water cut-off wells.

City staff discussed solids deposition at great length. The tunnel was eventually designed with a v-shaped bottom to maintain velocity over a wide range of flows.

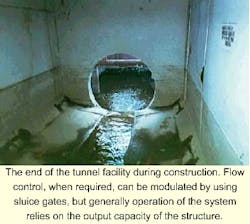

Flow control, when required, is by SCADA operated modulating sluice gates at the inlet and outlet of the tank. Generally, control is not expected to be needed, with operation relying on the outlet capacity of the structure under most conditions. The existing 42-inch interceptor was retained for additional storage capacity and to allow the tank to be taken out of service if necessary.

Construction of the project began in early September 1998. The pre-cast sections were manufactured by American Concrete Industries. The company procured three sets of custom designed forms to construct the individual sections. The sections were reinforced for H-20 wheel loading, used 5,000 psi concrete, and had steel bolt pockets cast into each corner. ACI provided 1 inch thick by 4 inch wide flexible butyl resin sealant and 3/4 in. stainless steel threaded rods, nuts and washers to join the sections. Each section was five feet in length and weighed 21,000 pounds. They were delivered to the site on flatbed trailers.

Construction was by Lou Silver Inc. On a typical day, an excavator dug the trench slightly ahead of the pre-cast installation. Clean excavated materials were used for backfill of the pre-cast sections already installed. Other materials, such as rocks, logs and materials otherwise not suited for backfill, were stockpiled on site for other uses.

Once subgrade was reached, the excavator placed 12 inches of crushed stone in the bottom of the trench. Workers adjusted the grade using lasers.

While these activities were taking place, another crew was attaching lifting bolts to a pre-cast section. Then a crane lowered the section into the excavation where workers placed strips of sealant against the face of the tongue end. Once the sealant was in place, the crane placed the section against the previously installed section. Workers used hand-operated hydraulic jacks and a custom designed apparatus that fit into the bottom bolt pockets to pull the sections together.

Crews trimmed the sealant that had been compressed and extruded into the tanks. The bottom joints and all bolt pockets were grouted flush with the surface.

The construction crew was commonly able to install 20 sections a day. Although work began with 75 of the sections already pre-cast and on-site, the concrete company could only fabricate six sections a day. Eventually the contractor caught up and had to suspend installation for two weeks while more sections were made.

Conclusion

On June 1, 1999, the David Brook CSO Tunnel was placed in operation. Approximately 80 percent of Bangor's sewage now flows through the facility on a continuous basis. Normal daily flows stay in the V-shaped area in the bottom of the facility. Several rain events have shown that the facility is operating as anticipated.

The total cost of the facility was less than $1.4 million, significantly less than either the planning level cost projection of $3.9 million or the preliminary design cost estimate of $6.9 million. Most of the project funds provided economic benefit to the local community, since the project was conceived and designed locally by City of Bangor staff, a local fabricator manufactured the pre-cast concrete sections and a local contractor constructed the project. Construction time was less than one season and caused virtually no disruption along Bangor's waterfront.

The facility's flow through design eliminated the need for expensive pumps and other sophisticated equipment. Only three small structures were required for SCADA control and monitoring equipment, leaving virtually the entire area above the tunnel available for future waterfront development and establishment of a riverfront park - both high priorities of the community.

About the Authors

John L. Murphy,P.E., is the Assistant City Engineer and CSO Program Manager for Bangor. He represents the city on the CSO Partnership Board of Directors, and on EPA's Urban Wet Weather Federal Advisory Committee. James D. Ring,P.E., is Bangor's City Engineer and Director of Public Services. He represents the city on AMSA and several state and local entities. James F. Seiler,P.E., is the project manager of the Davis Brook CSO Storage Facility and several other successful CSO control projects.