Pumping and Power: Coming Together

By Stephanie Morgan

In the past, since most primary lift stations relied on diesel generators, there were no alternatives to lift station backup. These days, however, more and more utilities are considering a lift station assurance plan that includes an independently powered backup pump capable of meeting system demands during wet weather, scheduled maintenance, new construction and emergency repair.

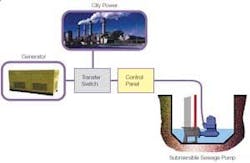

Traditional Lift Station Emergency Backup Pumping Design

Traditional lift stations require constant power in the form of a backup diesel-driven generator that provides power to the lift station pumps during an electrical outage. Backup generators are sized to handle the maximum horsepower requirements of the pumps during peak lift station flow demands. When a lift station experiences an electrical outage, the main control reacts to the power loss by starting the diesel-driven generator, and power is directed through a transfer switch to the breaker panel controlling the pumps. The generator, transfer switch, pump control and pump are the necessary components in the traditional backup system. If all four components of the system work during the power outage, lift station pumping will continue uninterrupted. Should any of the five components fail, pumping will cease and a sewage spill could occur depending upon:

- the prevailing flow

- duration of the outage

- surcharge capabilities of the gravity sewer lines feeding the station

All links in the system need to work successfully for the entire emergency system to function.

Rethinking the Contingency Plan

For decades, surface-mounted, diesel-driven trash pumps featuring automatic priming and solids handling capabilities have been the staple of sewer bypassing applications. Design features, such as automatic priming and an oil bath mechanical seal for indefinite dry running, have brought simplicity and reliability to the portable pumping market. Stationary lift stations can now benefit from these same features.

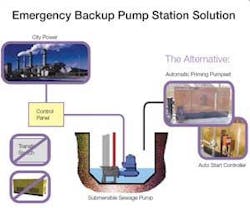

Backup Pumping instead of backup power

Backup pumping provides simplicity because the automatic self-priming pumpset is a stand-alone unit. The system is independent of utility line power and lift station pump control. Start and stop controls are provided by either a pressure transducer or float switches located in the wet well that activate the diesel- and natural gas-driven pumps when wet well sewage level rises to a predetermined height. The automatic priming feature removes air from the suction line, creating a vacuum that forces the sewage to rise, which primes the pump. The pumpset continues to operate and pump the required flow, then shuts off when either the wet well is lowered or the electricity is restored and the primary system takes control. The net effect is that the emergency backup pumping system and the lift station pump system are independent and do not rely upon each other.

When comparing backup power to backup pumping, it is important to remember:

- When using backup power, failure can occur with city power, the generator, the transfer switch, the control panel or with the electric submersible pumps, in which case, standby generators that create electrical power are useless.

- Backup pumping provides increased flexibility to perform repairs or preventive maintenance on permanently installed pumps, reducing repair or replacement costs associated with unplanned failure.

- Initial and ongoing costs are greater with generators. A diesel generator and transfer switch can cost between five and ten thousand dollars more than a diesel backup pump.

- Generators are usually load tested on an annual basis to ensure reliable power generation in emergency situations. The costs associated with load testing generators are significantly higher than those associated with flow testing an automatic priming emergency backup pump. To satisfy local requirements, contract electricians are often called upon to load test generators and can be the only qualified personnel able to work on a generator in the event of failure. Flow testing automatic priming emergency backup pumps is routinely handled by operators at no appreciable cost.

For collections systems across the country, there are many benefits to having a complete backup pump station. The ability to schedule and perform maintenance, continue pumping during repair, accommodate new construction and supplement the primary station during stormwater infiltration or power outages are a few of the higher profile reasons more and more planning boards are choosing backup pumping. The reliability of a self-starting unit that is independent of electric power reduces the risks associated with mechanical failure in both the traditional lift station and its typical generator-based contingency plan.

About the Author:

Stephanie Morgan is a technical writer for Godwin Pumps (Bridgesport, NJ). She can be reached at 856-467-3636.

Calvert County Chooses Backup Pumping Plan

The Board of Commissioners of Calvert County (Prince Frederick, MD) and the Calvert County Department of Public Works, Utilities Bureau, Division of Water and Sewerage (Calvert County) recently modified its Wastewater Pump Station Number Three. Utilities Bureau Chief Barry King needed to maintain from 1,900 GPM of flow at 130’ of total dynamic head (TDH) to 600 GPM of flow at 177’ TDH in a low-lying area sensitive to sewage overflows and spills.

“The purpose of this project was to increase the pumping capacity of the wastewater pump station to handle future sewerage flow reliably with the provision of a safety and backup measure to minimize the potential of future sewerage discharges,” said King. “The two general alternatives considered involved providing emergency pumping backup via standby power generation or standby pumping operation.”

Calvert County selected Godwin Pumps’ CD160M automatic self-priming Dri-Prime® Backup System (DBS) pump. This skid mounted, critically silenced pump is capable of flows to 1,900 GPM and heads to 260’, with solids handling capabilities to 3” in diameter. With this range of coverage, the CD160M pump is suited to be a reliable backup pump in the event of total lift station failure, and a more than capable supplemental pump for extreme weather events or routine maintenance and/or construction. Regardless of when it is needed, Calvert County’s DBS is designed to reliably withstand no-start periods via an optional battery charger and block heater. In addition, optional float controls automatically trigger this self-priming system to start, which then sends a signal to the main control center indicating that the primary lift station has either failed or is overburdened.

“[The DBS] has been a cost-effective alternative to the traditional safety and backup measure of standby electric generator installation,” said King.

“Calvert County is rapidly expanding, in both development and population. Naturally, the demand on the municipal sewer system has increased, and the need for a safe, reliable backup system was required,” said Godwin Sales Engineer John Inman. “The DBS solves many maintenance issues with the submersible pumps in the wet well, as well as power failures and other normal problems with pump stations. This backup pump should provide many years of worry-free, reliable service to the county.”