Multi-phase PFAS pilot testing saves time and expenses

In 2019, Middlesex Water Company (MWC) began planning for per- and polyfluoroalkyl substances (PFAS) and perfluorooctane sulfonic acid (PFOS) treatment at its Park Avenue wellfield in central New Jersey.

Later, in 2021, new maximum contaminant levels (MCLs) for perfluorooctanoic acid (PFOA), PFOS, and perfluorononanoic acid (PFNA) previously promulgated by the New Jersey Department of Environmental Protection became effective at a national level.

By this time, MWC had already embarked on a structured bench- and pilot-testing program for its new PFAS treatment facility. To determine how to bring this new facility online, MWC and its outside partners decided to incorporate a multi-phase pilot testing program that would provide the best data available to facilitate the final design and build of the new facility.

Multi-phase pilot testing for PFAS

Pilot testing provides a water utility an opportunity to evaluate different PFAS treatment technologies side-by-side. The testing can confirm the projections of bench-testing for media life and can also help evaluate how potential foulants or co-contaminants can impact treatment performance.

Additionally, pilot testing can demonstrate the performance metrics relevant to the utility’s regulatory agency. Other benefits include providing a hands-on experience for operations staff with the various technologies, and the establishment and confirmation of design criteria (e.g., empty-bed contact time, loading rate, etc.). MWC’s multi-phased pilot program consisted of both bench- and field-scale testing for its new Park Avenue treatment facility.

Bench-scale pilot

Bench-scale testing involves small scale experiments in a laboratory setting to assess methods or processes, verifying their feasibility and identifying any challenges before full-scale implementation.

When performing bench-scale testing, large amounts of data can be obtained in a short period of time to help screen potential treatment technologies more quickly. Rapid small-scale column tests (RSSCTs) are often used to assess the efficacy of adsorption media such as granular activated carbon (GAC) and anion exchange (AIX). By reducing particle sizes via grinding, RSSCTs allow for enhanced mass transfer and simulation of long-term field or pilot testing in a much shorter time frame. By reducing the particle size, column testing can be performed using a much shorter residence time since the smaller particle sizes allow for smaller column diameters, and ultimately less water needed for the study.

With RSSCT, results can be obtained in weeks, not months, in a controlled laboratory setting environment with a single water sample.

The bench-scale piloting goals for MWC were to effectively compare the GAC and AIX products that were under consideration for MWC’s PFAS treatment solution. This included a comparison of the impacts of trichloroethylene (TCE) and perchloroethylene (PCE) in the raw water, an analysis of each media’s effectiveness at removing hexavalent chromium, as well as the impacts of polyphosphate addition on each media. Piloting was performed using 700 gallons of raw water and employing a RSSCT approach with 3.5-fold particle size reduction, a 5x PFAS spike, a 2x PCE, and a TCE spike in select GAC columns with a test duration of 60,000 EBVs between June and August 2019.

The bench-scale results showed that short-chain PFAS compounds could be effectively removed via GAC or AIX, although the AIX resin would need to have three times the lifespan of GAC media for equivalent changeout frequencies. There were negligible impacts by GAC or AIX on sulfate and chloride. PCE/TCE inhibited PFAS treatment in the GAC media, and no measurable release of arsenic was detected. Polyphosphate inhibited short-chained carboxylates in the AIX media, but facilitated treatment of linear PFOS.

The bench-test findings clearly proved that GAC was the best technology for MWC to treat for PFAS efficiently and cost-effectively. MWC then worked with engineering and construction firm CDM Smith to develop a field pilot-testing plan, perform field piloting, and commence the design of MWC’s PFAS treatment system for its Park Avenue wellfield.

Field-scale pilot

Field-scale testing is performed on-site with operator involvement and more closely mimics full-scale operations. Field-scale pilot testing can be conducted in parallel with the design phase of the project. Additionally, it can be used post-start-up of the full-scale treatment to provide additional evaluation results.

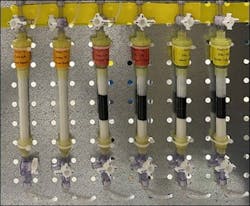

MWC’s primary field-scale testing goals were to verify the bench-scale test results. Field-scale testing reconfirmed the location of treatment with respect to the integration of the existing air strippers at the well field, while monitoring the GAC performance under actual conditions. Four different GAC media were evaluated with respect to their PFAS removal efficiency, head loss, and media changeout frequency.

The field-testing results showed that PFOA and PFOS were the driving compounds for media changeouts, and that shorter chained PFAS broke through quicker than longer chain PFAS. In the field testing, the top two performing GAC media were identified, no anticipated impacts to the existing corrosion control treatment were confirmed, and an anticipated timeframe for GAC media changeout was established.

As a result of the unexpected biological fouling of the GAC during field testing, it was determined that a means of filtration upstream of GAC would need to be incorporated into the design of the full-scale facility.

Opportunity for more piloting during construction

Based on the bench- and field-scale findings, MWC selected to design a new 12-mgd water treatment facility utilizing 20 individual 12-ft diameter pressure vessels with GAC, operating in a lead/lag configuration as a pair.

In 2021, during the construction phase of the facility, the MWC team realized that the COVID pandemic disrupted the supply chain for multiple pieces of major facilities equipment, delaying the contractor’s original schedule for completion. The bench-scale testing and field-scale testing performed during the design phase allowed MWC to quickly shift gears during the initial phase of construction and implement an interim treatment plan.

As such, MWC accelerated the installation of four of the 20 permanent GAC vessels to treat a reduced water flow. This allowed the wellfield to restart ahead of the 2022 summer peak demands and meet the MCL compliance requirements. An expedited permitting, procurement and delivery process for the four vessels was initiated. These vessels were temporarily installed outside and then relocated inside, once the main facility was operating.

Additionally, construction for a 200,000-gallon backwash holding tank, and a new sewer connection permit to discharge backwash water during start-up, was accelerated.

This installation and commissioning of the interim treatment system, while the permanent system was under construction, served as another means to pilot the future permanent treatment system. It also provided the owner, engineer and contractor with practical lessons learned prior to full-scale commissioning and operations.

One extremely important fact that MWC learned was the need to increase the volume of water used to forward flush the vessels and reduce the pH and arsenic levels during initial start-up. This ultimately led to an increased quality control of the GAC media by the vendor. In this way, the interim treatment system of four GAC vessels effectively allowed MWC to perform full-scale piloting by utilizing permanent equipment. These lessons learned helped mitigate uncertainty during the commissioning phase of the full facility.

Permanent treatment

MWC’s new 12-mgd GAC facility includes twenty GAC vessels, intermediate pumping, five 10-micron bag filters, a surge tank, site piping, a 200,000-backwash storage tank, conversion to sodium hypochlorite, connection to a sanitary sewer, ortho/polyphosphate, and a new standby generator.

Start-up of the permanent facility took place in three phases beginning with the commissioning of eight of the permanent vessels in April 2023, eight permanent vessels in May 2023, and finally with the relocation of the four interim vessels from outside to within the permanent facility in July 2023. Since this time, the facility has been operating year-round and the GAC media life matches what was predicted during the piloting phase of the project.

Summary

MWC gained valuable, project specific information by implementing multi-phased pilot testing for PFAS treatment before fully implementing its new 12-mgd water treatment facility.

By working together with the engineers, contractors and vendors to design a robust bench-scale testing system, along with a field-testing pilot that took advantage of construction of an interim treatment plant, MWC received helpful data points. These data points showed both the effectiveness, and the difficulties, in building a full treatment system utilizing GAC filtration. Additionally, the pilot provided data that allowed the MWC operations team to budget for the appropriate amount of media necessary to handle throughput when the new treatment center came online and was running at full capacity.

Although no testing program is perfect, MWC found that a multi-phase pilot program, along with taking advantage of opportunities for further testing during construction, can be a means to test and analyze new PFAS amelioration methods while continuing plant operations. Overall, a robust bench-scale and field pilot testing program can typically yield additional dividends beyond the normal expected goals.

About the Author

Brian F. Carr

Brian F. Carr, PE, is senior director of engineering for Middlesex Water Company in Iselin, New Jersey.

David J. Tanzi

David J. Tanzi, PE, BCEE, is senior vice-president at CDM Smith Inc. in Edison, New Jersey.