Finding A Home For Biosolids: Does Class A Provide the Answer?

By John Igoe

Over the years in the United States millions of tons of municipal biosolids have been land applied to forests, roadsides, nurseries, as well as pasture and agricultural lands, virtually without notice. This practice have been viewed as a convenient tool for sludge management and has proven to be beneficial as a nutrient rich substitute for commercial fertilizer.

However, many of the areas used for this purpose have now become populated due to urban and suburban sprawl. The land application of biosolids is now being viewed as a potential hazard to the public.

Agricultural land application accounts for almost 41 percent of biosolids disposal in the United States today. Due to the large volume of material being applied to agricultural land, the public has been looking very closely at the type of material being applied in their "back yard." The public is questioning the validity of the 503 regulations, and the US EPA is waiting for a report reviewing the regulations from the National Academy of Science.

Basically, the public is asking municipal and private firms that dispose of biosolids to offer assurances that the material that causes such an offensive odor and "looks" bad does not adversely effect their way of life. Questions asked include: "Will my children get sick if they breathe or handle this material?" "Will the animals that eat the hay that is grown with biosolids cause us to come down with some yet unknown disease?" "Is this how mad cow (BSE) disease started in the UK?"

The two major designations for biosolids are Class B and Class A. Class B material contains less than 2,000,000 MPN (Most Probable Number) fecal coliforms per gram dry solids and Class A less than 1,000 MPN. It might be said that Class A material is "more acceptable to the public."

Class A TreatmentSome of the treatment options that are widely used today to produce Class B biosolids have been employed for many years. Anaerobic digestion, composting, and lime treatment are just a few options used by treatment plant operations.Class A biosolids can be produced by using pre-pasteurization, drying, and incineration. Many vocal people today insist that all biosolids which are land applied should be Class A.

Pre-pasteurization to produce Class A biosolids is gaining favor. Pre-pasteurization systems can be retrofitted into any anaerobic digestion facility and will produce Class A biosolids after digestion. The process does not require the purchase of chemicals, and does not produce a gas stream; therefore a gas scrubbing system is not required.

The pasteurization process is simply a "bulge" in the pipeline feeding the anaerobic digester. The digested material can be dewatered using standard belt filter press or centrifuge dewatering procedures.

The US EPA 503 regulations describe pasteurization in very simple terms; heat the biosolids to 70°C (158°F) or higher and hold temperature for 30 minutes or longer.

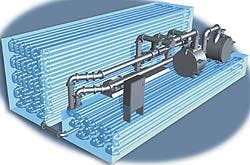

One of the industry's leading pre-pasteurization systems is the Eco-Therm™ Pasteurization System from Ashbrook Corporation. It features a patented process using a novel reactor design. The reactor, which has no moving parts, assures that the material will not short circuit, thereby meeting EPA requirements. Each particle is subject to the specified time-temperature requirement to insure pasteurization.

With the Eco-Therm™ System, a progressive cavity pump moves the biosolids material through a heater/heat exchanger. This raises the temperature of the biosolids to the prescribed 158-degree Fahrenheit level (70-degree Centigrade). Then, the biosolids discharge into a plug flow reactor and are detained for the requisite 30 minutes at temperature. (Note: This effectively sets total treatment time at 30 minutes.) Finally, after heat recovery, the heat-treated biosolids are channeled to an anaerobic digester for Vector Attraction Reduction.

The system can be scaled to accommodate a range of flow rates, including those typical in small to medium and even large publicly owned treatment works (POTWs). Energy consumption and O&M costs are low for the approach, which in part accounts for the more than 30 percent savings reported by current users, relative to total biosolids handling costs.

Vector Attraction Reduction (VAR) must take place during pasteurization, or immediately following, and is defined as the reduction of volatile matter by greater than 38 percent. There are additional alternatives to meet the VAR requirements when anaerobic digestion does not exist. This fact illustrates the flexibility of the pasteurization process as a retrofit for many installations that do not employee anaerobic digestion.

The pasteurization processing of liquid and liquid/solid suspensions has been used for hundreds of years. Louis Pasteur discovered in 1864 that heating wine to 160°F would eliminate the bacteria developing in the regions' wine process. The same method of pasteurization is used today in the milk, orange juice, and beer industries in the United States and around the world.

Pre-pasteurization processing of biosolids produces a material with "non-detectable" levels of pathogens and virus. The Class A product has a neutral pH and contains the nutrients which the agricultural community wants and plants need. This simple process is performed at a cost of approximately $91 per dry ton.

A number of manufactures offer pasteurization processes that have been successfully demonstrated to produce Class A biosolids. The continuous pasteurization process is one that is acceptable to the US EPA approval for four projects has been granted in California. A three-year demonstration project has shown the viability of the system and the ability to produce Class A biosolids on a cost-effective basis, without excessive operator attention.

ConclusionBiosolids in the United States and elsewhere in the world must be treated to eliminate disease. The beneficial use of biosolids will assist both the developing and developed nations to reduce operating costs to farmers and others. The public must be instructed in the true value of this natural material, which will increase the fertility of the earth, which, of course, we all depend upon.Education of the public must come initially from the government and at the same time from the generator and end user of the biosolids. The government and the generator must, of course, be cognoscente of the publics concerns and fears, and address them in a factual method that is understandable and assessable by the average person. WW/

About the Author: John Igoe is Product Manager for Ashbrook Corporation. He is a mechanical engineer with more than 20 years of experience in the biosolids industry. He is a recognized leader in pasteurization technology and is the Product Manager for the Ashbrook Eco-Therm™ Pasteurization Process.