Reclaimed Water System uses Vadose Zone Recharge Wells

by Jayendran Srinivasan

Approximately 20 miles northwest of downtown Phoenix in Maricopa County is the second fastest-growing municipality in the greater Phoenix metropolitan area – the city of Surprise. With a population of 104,000 that is estimated to exceed 179,000 by 2020, Surprise is also one of the fastest growing cities in Arizona. Surprise leaders realized that this anticipated growth, combined with limited surface water allocations and groundwater regulatory limits, would place a tremendous strain on the city’s water resources in the future.

In 2002, the city initiated a comprehensive Water Resources Master Plan with the goal of determining future water demands and the resources needed to meet those demands. Treated effluent from the city’s wastewater treatment plants is one of the renewable resources identified in this master plan that will allow the city to maintain adequate water supplies.

The city envisions that by build-out, a significant quantity of treated wastewater will be used either for irrigation or to recharge the city’s groundwater supply. To implement this plan and maintain compliance with permits required for plant discharge, local officials decided to expand the capacity of the Surprise South Water Reclamation Plant (SSWRP) from 7.2 mgd to 16.3 mgd.

But this presented a significant water resource management challenge. Much of the reclaimed water from the SSWRP in excess of direct irrigation demands was to be stored in recharge infiltration basins – an expensive option considering the area occupied by these basins and cost of land in Arizona. Additionally, the recharge basins have low infiltration rates resulting from soil plugging due to total suspended solids composed mainly of organic materials. As a result, the city looked for an alternative recharge method to handle the added effluent capacity.

Finding a Solution

In 2005, consultants from Lockwood, Andrews & Newnam Inc. (LAN), a planning, engineering and program management firm headquartered in Houston with an office in Phoenix, and HydroSystems Inc. (HSI), a Phoenix-based firm specializing in groundwater recharge and other hydrogeologic applications, proposed a technology called the vadose zone recharge system to help achieve the city’s water resource management goals.

The technology, which works like a condensed drainage pit, uses a cluster of specially designed wells installed in the unsaturated zone of sand and gravel material above the groundwater table, commonly known as the vadose zone. Reclaimed water, treated to Class A+ quality levels using advanced filtration methods, is pumped into the wells and percolates through the clay, sand, gravel and silt layers laterally and vertically into the groundwater aquifer.

“The vadose zone recharge technology takes less land area compared to other recharge methods and the permitting requirements in Arizona are suited for this type of technology,” said Floyd Marsh, LAN’s Phoenix office water resources manager and practice leader. “A water provider can accrue credits by storing reclaimed water supplies using this technology, recover those credits through future pumping, and enhance its water supply portfolio.”

Convinced that this solution offered the advantages the city was looking for, Surprise officials awarded the contract to the team on a direct-select basis in April 2006. LAN was chosen to provide project management, planning and civil engineering services, HSI was chosen for vadose zone recharge evaluation, design and permitting, and DLT&V Systems Engineering, Inc. (DLT&V) was chosen to design the electrical, instrumentation and control systems and its integration into the city’s existing water system SCADA located at the SSWRP.

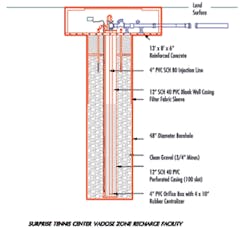

Vadose Well Design

To balance the volume of the reclaimed water coming out of the SSWRP and its subsequent recharge, the city decided to install the vadose zone wells in phases in conjunction with the expansion of the SSWRP.

Accordingly, the wells will be installed in four phases at two different locations in the city service area. The first location, which is adjacent to the SSWRP, has an estimated recharge capacity of 10 million gallons a day and includes approximately 32 wells. The first phase will consist of 15 wells and two subsequent phases will include 10 and seven wells, respectively. Other project elements include associated delivery pipelines, filtration systems, booster pump station modifications, and a control system.

The second location, the Surprise Recreation Campus Recharge Facility (SRCRF) site near the city’s new Municipal Center, is approximately four miles from the SSWRP with an estimated recharge capacity of 5 mgd and will include approximately 21 recharge wells.

In September 2006, following initial project planning, the city and the consultant team started the design phase of the project. After studying the geologic cross-sections and the groundwater flow direction at the two sites, the project team designed the recharge wells according to the site-specific soil and subsurface geologic conditions to enhance the flow-rate of the recharged water.

Each well will be 48 inches in diameter and drilled to approximately 180 feet. The depth of groundwater in the city of Surprise normally ranges from 300 to 500 feet. This means water from the recharge wells will permeate through more than 120 feet of sand, clay, gravel and silt before it reaches the groundwater aquifer, thereby becoming further purified through natural soil percolation.

To achieve economy of space, the wells will be placed in a rectangular formation with wells spaced just 100 feet apart from each other. This will also allow the wells to be tested individually or in clusters, based on which design or operational modifications can be made if required.

“The footprint of a vadose zone recharge well is so small that an entire group of wells can be accommodated in a few acres compared to several acres that will be needed for recharge basins,” said Kinga Stanek, senior project manager at Surprise’s Water Services Department.

Project Challenges

With the expansion of the treatment facility and the recharge well project happening simultaneously, one of the critical management challenges for the city and the project team was to coordinate the different design activities and anticipate construction without interrupting plant operations, while also maintaining project milestones.

To tackle these issues seamlessly, the city and the project team worked collaboratively on each aspect of the project. Biweekly project team meetings and regular site visits, in addition to individual task meetings, were scheduled to facilitate project understanding and observe existing infrastructure. Detailed project schedules, progress reports, and billing reports were maintained on a monthly basis to track and monitor activities. In addition, the project team also educated and kept the city staff involved, including the managers, designers, engineers and operators, on the design, technological aspects, construction, and testing and operation procedures of the vadose recharge technology and required filtration systems. This tight-knit, fully integrated team has been a hallmark of the project’s success to date.

Another issue that the team has addressed during the project is the quality of the water that will be recharged. While vadose zone recharge wells are less land-intensive and economical, they cannot be rehabilitated like other recharge technologies and therefore well lifespan is estimated to be only around five to 10 years. Consequently, the water being recharged into the wells has to be filtered to a very high level to prevent clogging due to particulates such as total suspended solids (TSS) and total organic carbons (TOC). In addition to slowing down the infiltration rates, these solid organic materials also affect the life of a well.

“The biggest challenge in most cases is the microbiology – biological plugging caused by microorganisms,” said Gary G. Small, HSI’s President and recharge manager for the project. “One of the things that we found in our experience designing and operating recharge wells was that typical reclaimed water has a high load of nutrients and this allows the bacteria already in the soil to flourish. So, disinfection and filtration at the surface helps to ensure that the water injected into these wells is of a very high quality.”

To increase the longevity and productivity of the wells, the project team evaluated and recommended an innovative filtration system for subsequent phases of the project. This filtration system, which has a 98 percent sediment removal efficiency (AFR Series-8 internal backflushing filter from Eaton Filtration of Portage, MI), uses a stainless steel mesh screen to filter the TSS, TOC and other organic material down to five microns. The project team used eight different criteria based on an exhaustive analysis to select the appropriate and most cost-effective filtration system: Design flow, foot print, pressure loss across filter surface, maximum particle size allowed through the filter system, particle size of sediment in reclaimed water into the filter, removal efficiency, back flush flow quantities and cost.

Conclusion

When completed and operational, the facility will use a multiple-step process to recharge the water from the SSWRP. The supply of high quality reclaimed water being delivered to the recharge wells will be diverted first into a contact tank after chlorine disinfection. This water supply will then be pressurized using booster pumps into a separate set of reclaimed water pipelines connected to the recharge wells. Reject water resulting from occasional flushing of the distribution lines will be diverted to an existing adjacent city sewer line and recirculated through the SSWRP for reuse.

The construction of the first phase of the project, estimated to cost approximately $5.25 million, will be underway in early 2008 and is anticipated to be completed in fall 2008. Phases two and three will be completed in the next two fiscal years. At the completion of this phase at the SSWRP location, additional vadose zone recharge wells will be designed and installed at the second location (Surprise Recreation Center Campus site). Costs of this project have been funded in large parts by wastewater customer user-rates and fees, as well as contributions from development-related fees.

By using a new technological approach, proper research and project management, the City of Surprise is well on its way to achieving its dual objectives of implementing effluent management and reclaimed water reuse to develop an important future water supply.

About the Author:

Jay Srinivasan is a Technical Writer for Lockwood, Andrews & Newnam Inc., a full-service consulting firm offering planning, engineering and program management services. Srinivasan joined LAN in July 2006. He may be contacted via email at [email protected].