Best-Tasting Tap Water Mixed with Success

Imagine having the best tasting water in America. That privilege is a reality for Mt. View-Edgewood Water Company (MVEWC). The utility won top honors in the National Rural Water Association’s 13th Great American Water Taste Test held in Washington, D.C., in 2012.

Additional honors went to Mike Craig, MVEWC Field Manager, who was recognized as the Water System Operator of the Year in a ceremony at City Hall. This highly coveted award, presented by Evergreen Rural Water of Washington State, recognizes the top water system operator in the State of Washington for superior achievement.

Since 1925, the Mt. View-Edgewood community has worked together in building a member-owned utility to provide quality drinking water and fire protection. MVEWC does not add any chemicals to the water - it’s delivered to customers without chlorine, fluoride, or any other additives. The water is filtered slowly and naturally through glacial gravels deep beneath the earth’s surface. The aquifer does not contain naturally occurring elements that affect taste, acidity, or hardness. The staff focuses on prevention, best practices of operations, design, and continuous improvement in delivering the best-tasting water nature has to offer.

The Water Company’s service area is located on a glacial drift plain, which ranges in altitude from 50 to 500 feet, gradually rising from northwest to southeast. The larger drift plane extends from Thurston County north to southern British Columbia and is chiefly the product of glacial and glaciofluvial processes of the most recent glaciation. The geologic conditions occurring in the MVEWC service area are a direct reflection of the glacial activity. They have a groundwater system that draws water from wells in underground aquifers. MVEWC has ten wells that range from 100 to 419 feet deep. Water is pumped from the well in a deep, glacial aquifer. The pH is 7.2; hardness is 4 grains per gallon or, specified another way, 70 ppm or 70 mg/L (1 grain per gallon equals 17.1 mg/L of hardness).

MVEWC storage consists of two steel tanks (the South Reservoirs), which provide a combined total of 1.2 million gallons of storage; and one steel 1.0-million-gallon reservoir (the North Reservoir). All tanks are equipped with emergency generators, a backup server and telemetry controls.

Built in 2000, the North Reservoir is 32 feet tall and 80 feet in diameter with the overflow at 29 feet. It was designed with a 16-foot-tall inlet riser pipe and an outlet pipe placed at 180 degrees opposed to the inlet.

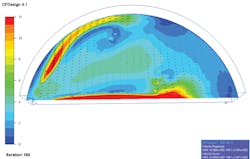

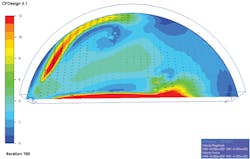

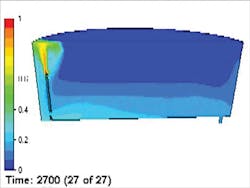

Subsequent Computational Fluid Dynamics (CFD) modeling by Tideflex® Technologies determined that this configuration is still highly prone to stratification and short-circuiting. In summer, inlet water is colder and denser; therefore, it is negatively buoyant and it sinks. Although the physical separation of inlet and outlet pipe makes intuitive sense, science proves that it does not improve mixing and it does not prevent the tank from stratifying and short-circuiting. The key to achieving complete mixing - and thus improving water quality - is the proper design of a multiport mixing system that distributes the inlet flow momentum through the tank and ensures inlet jets reach the water surface during negatively buoyant scenarios in the summer.

During investigative sampling (at the discharge), the North Reservoir had a total coliform positive result and a heterotrophic plate count (HPC) of 250 colony-forming units per milliliter (cfu/mL). Follow-up in-tank sampling indicated HPCs at over 30,000 cfu/mL at the top. The HPC is normally between 0 and 8 for MVEWC’s system. The utility determined that the tank was severely stratified, causing the elevated HPCs throughout the tank.

MVEWC turned to Tideflex Technologies for a solution. Using data from MVEWC, along with CFD and field-validated models, the company engineered a Tideflex Mixing System (TMS) to ensure complete mixing within the North Reservoir.

The inlet riser was converted into a multiport TMS with three Tideflex Inlet Nozzles. The quantity, size, relative stiffness, elevation and discharge angles were designed based on CFD and field-validated models. MVEWC normally cycles the tank daily between 21 feet and 29 feet, recognizing that sufficient turnover to minimize water age is very important for ensuring that quality water is being delivered to MVEWC customers. The TMS simply utilizes existing differential pressure available in the distribution system as the only energy source to mix the tank, eliminating the need to pay for the energy source twice.

Tideflex Valves used within the TMS have a variable orifice that enables maximized jet velocity at all flow rates. Higher inlet jet velocities will produce circulation patterns within the tank that not only maintain water quality by mixing the entire tank but also help prevent ice formation in cold weather. The TMS is truly a green technology, while the all-elastomer construction of the valves renders the system virtually maintenance free.

“After proper mixing with the Tideflex Valves, we eliminated the coliform and the HPC dropped to 7,” said Craig. “We test our reservoirs monthly for HPC and they continue to pass well below the standards,” he continued.

“Keeping our water pure from the source to the tap makes more sense than allowing it to become contaminated and then trying to purify it with chemicals,” said Marc Marcantonio, MVEWC general manager. “Mother Nature provides us with a pure, naturally filtered product. It is our job to make sure we preserve that quality.”

For more information about the Tideflex Mixing System, contact Tideflex Technologies at 412-279-0044 or visit www.tideflex.com.

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles