Multi-barrier packaged system treats potable and industrial water

Integrated technologies, consisting of adsorption clarification and mixed media filtration, ensure compliance of safe drinking water.

Siemens Water Technologies’ next-generation packaged pre-engineered water treatment plant, the Trident® HS system, provides multi-barrier protection for the treatment of all surface water and groundwater sources with variable water conditions, such as high turbidity, color, and cold water conditions. The system removes iron, manganese and phosphorus, and also treats industrial process water.

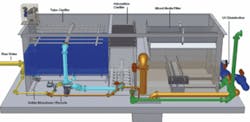

The system’s design is based on Siemens’ Microfloc Trident® packaged water treatment technology that consists of adsorption clarification and mixed media filtration. This technology integrates a specialized tube clarifier that uses sludge recirculation for increased gross solids removal. An ultraviolet (UV) disinfection system for final effluent treatment completes the package.

Collectively, these integrated technologies allow the Trident HS design to provide a minimum of 4-log reduction credit for Cryptosporidium and Giardia. The system treats raw water with a maximum 400 NTU, 100 true CU, or 400 combined turbidity and color, with iron and manganese of less than 10 ppm. The packaged water treatment plant ensures compliance, while providing exceptionally safe drinking water.

The Trident HS process

The Trident HS multi-barrier approach to water treatment consists of specialized high-rate tube settling, adsorption clarification, multi-media filtration and UV disinfection (Figure 1). These four treatment processes individually and collectively provide a consistently high-quality, treated water effluent.

First, the Trident HS system uses high-rate 60°-inclined tube settlers to provide for a greater effective clarifier settling area. Two layers of tubes minimize dead space at the ends of each clarifier tank. Sludge recirculation further enhances the solids removal process.

Next, the Adsorption Clarifier® system is an upflow treatment process that combines flocculation and clarification in a single-step process. As a result, the system uses 80% less space than a conventional treatment process. The Trident adsorption clarification media does not form a floc that can settle, but rather uses a special rolled and scarified buoyant synthetic media. Adsorption Clarifier units have been designed to operate at rates of 5 gpm/ft2 to 15 gpm/ft2, achieving turbidity removals of 75% to 95%.

After passing through the Adsorption Clarifier system, water then flows through a 30”-deep multi-media gravity filter bed consisting of three or more granular materials differing in size and specific gravity. This mixed media, which is typically anthracite, sand, and garnet, forms a coarse filter at the top and becomes progressively finer towards the bottom of the filter.

Multi-media filtration allows for a high specific area filter bed in a small filter footprint. This coarse-to-fine design with high specific surface area ensures optimum particle capture for production of high-quality potable water.

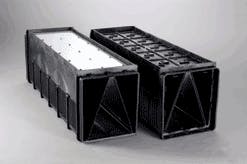

The filtered water is then collected in the MULTIBLOCK® filter underdrains with Laser ShieldTM direct media retention system and sent to the clear well. These underdrains are an integral part of the Trident HS design and offer the proven effectiveness of dual compensating lateral underdrain technology. The dual compensating design provides primary and secondary flow distribution chambers, compensating orifices between chambers and distribution orifices on top of the block for simultaneous uniform distribution of air / water and water-only backwash. Simple, snap-together construction joins the blocks to form laterals. No gasket seal between the blocks is necessary. The absence of a gasket or O-ring eliminates rolling and lubrication during the joining process. Lightweight NSF® Standard 61-approved structural foam HDPE construction simplifies installation, while providing corrosion resistance.

Once installed, MULTIBLOCK underdrains evenly collect filtered water. In the Trident HS design, filter media is supported directly utilizing Siemens’ unique Laser Shield direct media retention design. At 1.5-mm in thickness, the stainless steel Laser Shield system’s thin, low profile design does not reduce filter space in the Trident HS system. The open slot design is backed by more than three decades of media retention experience. Single, dual or mixed media configurations with media of 0.2 mm or larger are directly supported with the Laser Shield system and allow upgrading to mixed media in the future to increase plant capacity through higher filtration rates.

Finally, Siemens’ Barrier® M UV system provides the fourth and final treatment barrier of the filtered water before distribution. The Barrier M system is a medium-pressure UV unit, located in the filter effluent line. The UV is only in operation during the filtration cycle. Complete inactivation of waterborne pathogens including Cryptosporidium and Giardia is guaranteed. UV also offers the added advantage of no harmful disinfection by-products that commonly occur with chemical disinfection.

In field operations, the Trident HS system has performed exceptionally well, treating a wide range of waters with raw water turbidity ranging from 15 to 400 NTU and resulting filter effluent turbidities averaging less than 0.1 NTU. The Trident HS system two-step clarification uses both tube and adsorption clarification for complete redundancy that ensures optimal performance in the event of a system upset. The tube clarifier removes the majority of solids prior to the adsorption clarifier while the adsorption clarifier further reduces the solids loading prior to filtration and increases the filter run time.

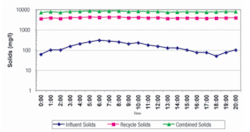

The sludge recycle system’s steady-state solids concentration easily handles raw water “spikes” in solids. The recycle concentration is maintained between 3,000 and 6,000 ppm in the tube clarifier with waste from the adsorption clarifier averaging 400 to 600 ppm. Influent solids to the unit are much lower, so even with significant changes in influent quality the overall solids concentration in the tube clarifier changes very little (Figure 2). Recirculation of the sludge also improves organics (TOC) reduction by increasing floc contact time and frequency.

With raw water iron and manganese concentrations of 10 ppm, filter effluent concentrations are typically less than 0.05 ppm for iron and 0.03 ppm for manganese. Effluent water color is less than 2.0 CU.

The Trident HS system will readily meet a 4-plus log removal credit for Cryptosporidium and Giardia, with the potential to achieve 6.5- to 7.5-log removal credit. Individual component contributions include: tube clarifier 0.5-log credit; adsorption clarifier 2.0- to 3.0-log credit; and filter effluent turbidity <0.15 NTU 1.0-log credit, with the UV system adding an additional 3.0-log credit.

Conclusion

The operational flexibility and proven component design of the Trident HS system provide a wide range of benefits. The pre-engineered design can handle “tough to treat” surface and groundwater sources, with up to 400 NTU turbidity and 100-plus CU. Its multiple barrier treatment steps provide not only 4-plus log removal credit for Cryptosporidium and Giardia, but also double clarification with the Adsorption Clarifier system as well as from the tube settlers. High steady-state sludge concentration/ recirculation in the tube clarifier absorbs water quality spikes and ensures consistent performance.

Compared to other designs, the system reduces waste volume and removes more organics (TOC). Finally, the Trident HS system has a footprint that is 25% to 50% less than that of conventional plants, which translates to lower installation costs.

Author’s Note

Patrick J. DiBenedetto is international sales manager for Siemens Water Technologies’ Memcor, General Filter and Microfloc product lines. Located in Ames, Iowa, Patrick joined Siemens Water Technologies (then USFilter) in 2004, and has more than 25 years of industry experience. He has a B.S. degree in Civil Engineering and a M.S. degree in Environmental Engineering, both from the University of Wyoming in Laramie. For more information, contact the author by email at: [email protected].