WRc verifies ViroFilter™ treatment removes phosphate

Independent tests demonstrate the viability of a phosphate removal system used to meet strict environmental regulations.

An independent trial undertaken by the UK Water Research Council (WRc) in 2005 demonstrated the viability of Virotec’s flow through ViroFilter treatment systems for meeting increasingly strict phosphate discharge consents.

Test units were fitted in-line with secondary effluent passing through beds filled with Virotec’s porous media. This passive system requires minimal power and maintenance and is suited for unmanned or remote sites, providing an economic alternative to chemical dosing. High phosphate removal efficiency is achieved in relatively short HRT. Trace metals polishing and further BOD reduction is achievable.

A number of key advantages are associated with ViroFilter applications:

• The technology provides an effective and simple system for phosphate removal immediately prior to final effluent discharge. This eliminates the need for ferric addition and minimizes sludge production, particularly relevant for smaller municipal works (<2,000 PE).

• Use of an immobilized bed allows variations in hydraulic flow and phosphate concentration to be handled without problems.

• Discharge consents can easily be met, removing effluent phosphate to below 1 or 2mg/l. Typical efficiency of phosphate removal is in the range of 80% - 85%.

• Removal of trace metals also takes place and they are held in a non-leachable form.

• The production of Virotec’s treatment media and its utilization in its ViroFilter systems provides a sustainable process, creating reusable and recyclable products from an initial environmental problem.

Virotec commissioned the WRc to evaluate ViroFilter systems for suitability as a phosphate removal medium. They used two- to eight-millimeter pellets in a secondary effluent test system comprising two six-meter horizontal pipes to simulate commonplace submerged horizontal-flow reed bed systems.

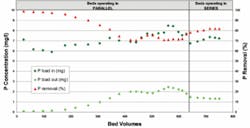

WRc researchers evaluated the test units (reactors A and B) in parallel for 22 weeks and subsequently for five weeks in series. To determine whether pH adjustment had any effect on performance, influent to Reactor A was dosed with hydrochloric acid to reduce pH to 6.5-6.8.

Influent phosphate was 6-9 mg/l PO4-P and the HRT was 4-12 hours for parallel reactors, and 12-16 hours for series reactors. Average P-removal rates of 80-85% were achieved, with improved efficiency with reactors in series. The P-removal capacity in the study (5 kg P/tonne of media) had not reached ultimate levels in over six months even under high loading rates, supporting data from a longer-term Virotec study reporting P-removal capacities >12 kg P/tonne. The minimum predicted bed lifetime was at least 20 times that of gravel media in a reed bed.

Little difference in P-removal efficiency at different influent pH (76% versus 80%) was evident, implying no need for influent neutralization. With reactors in series, increased phosphate removal was achieved (-85%).

Final effluent was lower in solids and COD, and improved in color and odor. Operating the reactors in series further enhanced these improvements in effluent quality. The study concluded that ViroFilter systems are suited for tertiary treatment at small wastewater treatment works without chemical dosing but also at larger sites, downstream of chemical dosing to provide polishing to meet strict phosphorus consents.

Virotec’s media has a variety of applications in addition to phosphate removal including elimination of metals from industrial wastewater such as electroplating, tannery, metal refining effluent, and wood treatment waste. In the UK and USA, pilot trials have demonstrated the media’s ability to treat acid mine water drainage. Other applications include soil remediation, removal of arsenic from drinking water, the construction of permeable reactive barriers, and aquaculture pond treatment.

Author’s Note

Simon Tillotson is the general manager of the UK company Virotec Europe Limited. For further information contact the author by email at: [email protected].