Water Disinfection Enhanced with Ultraviolet Light

By Jon McClean

Use of UV as a Legionella barrier for indoor and outdoor water features is another way to assure disease prevention.

Use of ultraviolet (UV) light has become standard practice in many industrial and municipal water treatment processes. The technique has been extended to effective treatment of emerging [chlorine resistant] species such as Cryptosporidium and Giardia, and also for de-chloramination of pool and spa and splash pad water.

This article discusses UV light use as an effective barrier against Legionella pneumophila, and highlights successful applications in indoor and outdoor water systems and features. As use of water as a decorative feature – ponds, fountains, waterfalls or pools – grows, so measures need to be taken to ensure these innovative attractions aren’t the source of illness or even fatality.

History of a Technology

UV light was discovered in 1801. It took over 100 years to develop lamps and power supplies to allow its application on an industrial scale. A drinking water plant treating 0.2 million gallons a day (MGD) of potable water briefly used it in Marseilles, France, in 1910. General chlorine application in drinking water after World War I, though, led to UV being used only in municipal applications where chlorine couldn’t be used.

Irradiation with UV light was routinely used to address vitamin deficiencies caused by poor diets during the war years in Europe. And, in 1937, directors of Sherwood Colliery, Mansfield, England, installed a “Light Corridor” miners would walk through after showering and before dressing, as a means of providing artificial sunlight to those working underground to overcome vitamin deficiencies.

UV was successfully used for medical and therapeutic applications from the 1940s until the mid-1980s, when clinical drugs became widely available over the counter and were able to address root causes, rather than merely dealing with a symptom of conditions such as psoriasis.

Industrially, a number of process users of water such as breweries and pharmaceutical plants adopted UV as a means of extending sub-micron filter runs, or preventing spoilage. In many industries, it was the only available means of ensuring water was free from harmful organisms, such as fish farms, crab grow-outs or for shell fish depuration. Early systems lacked meaningful UV monitors, optical fouling wasn’t easy to remove, and high prices meant the technology didn’t gain widespread acceptance until the 1970s.

By 1994, UV light was being successfully applied to de-chloraminate swimming pools, gradually replacing ozone as the oxidant of choice. Responsible manufacturers wouldn’t advocate replacement of chlorine using UV; rather, it was seen as a complementary technology. UV has the advantage of having no residual effects, which does mean a chemical regime is needed for residual protection. Chlorine can effectively be removed via UV, so the injection point should be post-UV when used.

Today, UV use has been extended to disinfect splash pads and pools as a method of mitigating against Norwalk virus on cruise liners and offshore accommodation platforms, usually used in combination with a chemical regime that provides an effective residual.

How does UV work?

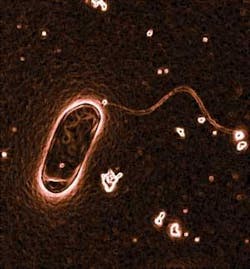

Near 260 nm in wavelength, UV has the ability to break bonds in the DNA of virtually all living organisms. As the cross bonds absorb the UV light, they break and form bonds with adjacent bases. This process is called dimerization. The process is generally irreversible at normal disinfection doses, and the damaged DNA ceases to permit any normal function for the organism. Replication immediately ceases as the organism is rendered non-viable. In decorative features, photoreactivation or photorepair could be a problem unless water is recirculated as this will ensure the kill is higher than the repair.

A growing number of organisms have developed immunity or advanced resistance to chlorine. Cryptosporidium and Giardia, for instance, can be present in municipal drinking water supplies and are now treated using UV light, as is Listeria monocytogenes which is effectively disinfected using UV at many food manufacturing plants.

UV light is a physical, non-intrusive method of disinfecting water that doesn’t affect the chemistry, pH, smell or color. It has no residual properties, and so systems that use it without any chemical residual should ensure they’re periodically chemically cleaned, as an infestation in the biofilm, or in a showerhead cannot be treated using UV alone. Dead-legs should be removed whenever possible.

Legionellosis is a highly infectious disease that takes two distinct forms; Legionnaires’ disease and Pontiac fever. Producing symptoms similar to influenza, the latter is seldom fatal. Legionnaires’ disease is the more severe form of the infection and leads to pneumonia and sometimes death. The CDC estimates that between 8,000 to 18,000 cases of legionellosis occur each year, although these numbers are most likely under-reported. The fatality rate of Legionnaires’ disease is between 5% to 30%.

The organism is dormant below 68°F, and can replicate and grow between 68°F and 122°F. The growth rate is highest between 95°F and 115°F. These conditions can easily be reproduced in a water feature in direct sunlight, a cooling tower, or air scrubber – thus making both indoor and outdoor water features an area of vulnerability.

Serologic surveys of seafarers on cargo vessels , and also those spending extended periods on offshore accommodation platforms show that a high proportion have antibodies to Legionella pneumophila, which suggests presence of and elevated risk of legionellosis from these environments, too. The risk of infection isn’t just localized to the water source. The 2004 outbreak in France at Pas de Calais that left 18 people dead showed that the organisms could be carried up to 3.5 miles from the source by wind.

An outbreak traced to an ornamental fountain in mid-2005 in Rapid City, South Dakota, killed one person and made 17 others ill. Another outbreak in Spain in December 2005 involving 15 cases also was tracked to an ornamental fountain in a shopping mall. The outbreak at a Quality Inn in Orlando, Florida, in March 2005, was traced to a spa with inadequate chlorine. And the outbreak in April 2008 in Mendon, Vermont, was traced back to a hot water tank. The majority of outbreaks do originate from cooling towers, where conditions are often ideal for growth, yet all water features are vulnerable unless properly maintained

In a number of situations, chemicals in the water may have a detrimental effect on flora or fauna in or adjacent to the water, or indeed the feature itself. As features designers and architects develop more sophisticated features, so UV will continue to be incorporated as it doesn’t change the water chemistry, smell or color. Some chemical smells are unattractive and cause a nuisance to people who work in them all day, such as a water feature in a hotel lobby. Typical maintenance for a UV system can be carried out by onsite facilities staff, and UV system status can be monitored using building management services networks.

Conclusion

UV has a wide role to play in making sure that both indoor and outdoor water features remain safe, and aren’t a cause of waterborne illness. When properly applied, the technique can provide an effective barrier and eliminate an often overlooked source of problems.

Author’s Note:

Jon McClean was president of Aquionics Inc. until April 2008. Now a consultant, McClean is working on product development for a new company. He has 22 years experience within the UV industry, and is often asked to speak and present papers at technical conferences. Contact: 513-407-6793 or [email protected]