There are two minimum requirements for civilization: a sewage system to carry away wastewater, and a consistent and reliable water supply system to provide water for drinking, bathing, and irrigation. A water supply system consists of several components. These include a source of water (groundwater, freshwater pond or lake, man-made reservoir, etc.), a system to extract and transport water (groundwater wells, aqueducts, or water pipelines), a facility to treat the water so as to remove impurities and make it potable before use, and a water storage system that holds excess water and provides for periods of low water supply or evens out flows during periods of variable usage.

Every city and town in history has needed a ready source of water and a means to store this water for future use. Water supply flow rates never exactly match water usage rates. During periods of excess inflow, unused water needs to be conveniently and safely stored for use during peak demand times or for emergencies such as fires. The use of modern water towers to provide pressurized water flow for commercial and domestic use began in Great Britain in the 19th century. Utilizing steam pumps for refilling, these towers consisted of tall, exposed inverted U-shaped pipes. This structure allowed for pressure relief, and convenient measurement of water usage. In the Victorian era, water towers tended to be ornate, with decorative masonry and wood enclosures. As cities of the industrial era grew in size, standpipes were replaced with ever larger water tanks.

Consumer Needs Both Big and Small

In the United States, the total (domestic, commercial, farming, etc.) average daily per capita water use comes to about 150 gallons per day, with almost 100 gallons per day consumed for domestic use. American daily water consumption varies with climate with arid regions (such as Nevada at 189 gallons) using more water than wet regions (like Maine at 51 gallons). The main reason for this difference is the outside use of water for gardening, swimming pools, and such, in hot, arid climates. By comparison, indoor use for toilets, baths and showers, clothes washing, cooking and dishwashing, and drinking is fairly constant nationwide.

And not every water storage operation has to include a massive tank and distribution system servicing an entire township or city. Individual residences and businesses (especially those in more rural or isolated areas) can take advantage of water storage systems scaled to their needs.

And at the small end of the water storage scale are companies like Rain Water Solutions, which provides rain barrels, cisterns, and related fixtures. Their 50-gallon Ivy model rain barrel has an innovative design and is made from 50%–100% recycled materials. Its screened inlet, locking lid, and linking capacity provide safety, security, and convenience. The larger, 65-gallon, Moby rain barrel comes equipped with a large capacity overflow, 3/4-inch spigots that connect to standard garden hoses, and can be expanded with multiple units to provide increased storage capacity. Their large-scale cistern units are customized rain harvesting systems ranging in size from 1,000 gallons, to over 60,000 gallons. They come with all plumbing and pump installations included, are made from a range of materials (plastic, fiberglass, concrete, or steel), and can be installed above or below ground.

Operational Requirements and Health Standards

In general, all water storage systems large or small need to be resistant to weather and temperature variations while handling snow and rain, must minimize the potential for the formation of algae (and thereby reduce chlorine treatment costs), have to be structurally stable and resistant to wind and seismic loads, and have to be self-standing without the need of support structures such as exterior columns and reinforcements. They also must screen out impurities such as debris and disease vectors, provide an aesthetically-pleasing architectural appearance, and be lined with coatings that reduce maintenance costs and the need for painting. Lining systems for steel and concrete tanks used for potable water storage are unique in as much as they need to meet standards such as NSF and ANSI 61; they also have to maintain good bonding strength and staying power.

Developed by the by the National Sanitation Foundation (NSF, a global independent public health and environmental organization), and the American National Standards Institute (ANSI, which oversees the consensus for developing standards for manufacturing and procedures in the United States), the water treatment and storage requirements of NSF/ANSI Standard 61 (NSF-61) are stringent guides for the control of equipment that either comes directly into contact with potable water, or materials, chemicals, and equipment that are part of the potable water production and supply system.

Meeting these standards requires a material to pass a series of tests that involves contact with basic cold water at different pH levels, up to a more extensive full spectrum chemical certification. The point of these tests is to determine the potential for leaching out of the material or coating in question. This is done by testing the contact liquids before and after exposure to estimate the reactivity of the water storage systems coatings and covers.

Several companies provide both the products and services needed to meet these regulatory standards for water storage tank coatings and liners. Two of the most prominent are Amtech and Induron.

For almost half of a century, Amtech Tank Lining and Tank Repair has been installing corrosion protection lining and providing repair service for liquid storage tanks used by a wide variety of industry, municipal, and commercial applications (potable water, fire suppression water, wastewater, chemicals, oil, gasoline, fuel, and petroleum products). Servicing laminate, concrete, fiberglass and steel tanks, their product line includes AT BiFlex Coatings & Linings, PLS 360e Tank Linings, DuraChem 500 series and DK2, Poly Lining AST Tank Bottom Systems, AmTech Poly-Line, and HydraStone cement linings. Their more specialized products include the HydraStone lining, which is used for steel potable hot water tanks, and the BiFlex FRP systems, which provides waterproofing for fiberglass tank linings and other laminate tanks. But for general use water storage tanks, there is the DuraChem 580 PW lining system. It adapts well for steel and concrete tanks. Its flexibility and elongation characteristics in response to stresses caused by temperature changes (air temperature, sun heating, and wind deflection can cause expansion and contraction) ensure continuous bonding to the tank wall substrate. The 580 PW is applied by high-temperature, high-pressure sprays resulting in 500-psi adhesion strength.

Induron Protective Coatings Inc. specializes in water storage tank coating systems. From traditional coating systems to advanced ceramic epoxy coatings and potable water epoxy paint, Induron provides a wide variety of finishing products. Their coating can be applied to potable water tanks at the time of construction or used in recoating operations for potable water tank maintenance, and their potable water epoxy paint is used where high-performance systems or coating with lower VOC content are required. For example, their PE-70 epoxy is a self-priming multicoat system for steel, ductile iron, or concrete surfaces exposed to potable or process water, splash, fumes, or spillage of water-borne chemicals and exposed to aggressive industrial environments. This is a two-component, high solids, ceramic modified self-priming epoxy coating formulated for superior resistance to water, water-borne chemicals, and other aggressive environments. It meets the requirements for NSF/ANSI International 61 for potable water immersion service in tanks of 1,000 gallons or greater capacity.

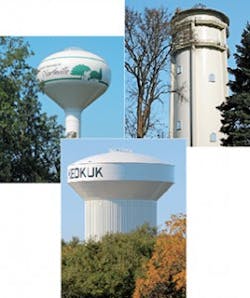

Clockwise from top right: Standpipe,

hydropillar elevated tank, and

waterspheroid elevated tank

Types of Water Storage Structures and Fittings

The most familiar means of storing water for domestic urban, suburban, and township use are water towers. Every small town and large city in America uses them; they form a fixture in a town’s skyline. These are elevated structures that support a water tank at a sufficient height to allow for an elevation head whose resultant pressure allows for the efficient distribution of water through its system of water supply pipes.

The reason for reliance of gravity to provide water flow is simple: Such a system is immune to electrical power outages. Firefighting operations and water distribution can therefore continue even if electricity is knocked out. No pumps are required, except to refill the tank’s reservoir.

The water tower’s reservoir containing its water is usually sized to be sufficient for most emergency and peak use conditions. This provides a sure capacity for the water supply system as the level in the tower falls with use during a typical operating day and is pumped full again during the night. Not every water tower stores potable water, some are uses specifically to supply water for firefighting or industrial processes. A variation on the water tower is the simpler standpipe (basically a large vertical pipe filled to provide a specific pressure head).

Often unseen are the internal fixtures and piping that make up the heart of the tank’s distribution mechanism. The fixtures can be highly specialized, even customized, for use in a particular tower. It can be an engineering, as well as a manufacturing, challenge to provide the fittings and assemblies that meet the operation requirements for these systems.

The Baker Water Systems Division of the Baker Manufacturing Co. is a firm that meets these challenges as it manufactures a wide range of water service and storage products, including tank fittings and assemblies. Founded in 1873, it is one of three divisions including the Baker Casting Division (which pours gray and ductile iron castings) and the Haight Pump Division (which produces gear pumps). The Baker Water Systems Division produces products for residential, municipal/industrial, and environmental use. Baker Mfg. Co., LLC.–Monitor Division manufactures pitless units and booster stations which may connect to a water storage tank or facility. Monitor’s pitless units are high-capacity groundwater wells (to accommodate flows ranging from as little as 5 gallons per minute to large flow rates of 5,000 gallons per minute), which may be used to pump groundwater to a storage tank, facility, or home. Custom-designed for each application, the Monitor in-line pitless Booster houses a submersible pump and motor below ground in the low-pressure suction tank reservoir. The unique design eliminates the need for a costly pump house and removes the hazard of confined space entry while reducing noise.

3,000-gallon galvanized steel tank

The water towers themselves are constructed from a wide variety of materials: steel, reinforced concrete, prestressed concrete, wood, fiberglass, or brick. These structures are lined with an interior coating to prevent leaking and protect the water from contamination. The water is stored in structures of various shapes (ellipsoids, tear drops, cylinders, spheres, etc.). A standard water tower has a height of 130 feet and a minimum diameter of 13 feet. The tower structure can also house storage rooms and operational centers that allow operators to automatically monitor and control pump refill operations.

The design, manufacture, and construction of water towers is one of the oldest engineering tasks of the industrial age, as necessary to the modern age as the railroads and the skyscraper. Many firms specializing in this work are over 100 years old, having gotten their start in the early days of industrial America.

As one of the oldest of these firms, CB&I is a major infrastructure supplier and builder, including the design and construction of potable water storage tanks. CB&I built their first elevated water storage tank in 1894, pioneered the transition to welded steel tanks in the 1930s, and developed the original Watersphere, Waterspheroid, and Hydropillar storage tanks. CB&I provides turnkey design and construction services, taking projects from conception through start up. As a long-lasting company with extensive experience, CB&I has built more than 25,000 elevated water tanks over the past century. During this time, they have developed many advanced construction techniques, such as a unique trailing scaffold system that makes construction safer and more efficient while improving inspection access. CB&I offers three styles of elevated water storage tanks:

- The Waterspheroid tank was developed in 1954 as a larger-capacity alternative to the original Watersphere tank. They are available with storage capacities of 150,000 to 2,000,000 gallons. They are aesthetically pleasing, with low capital and maintenance costs, and occupy a small footprint relative to their storage capacity. Standard security and safety features include flush threshold steel doors with deadbolt locks, and interior ladders allowing easy access during inclement weather. The pedestal provides storage space or housing for pumps, valves, piping, telecommunications, and controls.

- The Hydropillar elevated tank features an all-steel support pillar with a multipurpose interior space. Developed in 1962, Hydropillar elevated tanks are all-steel, all-welded structures that feature large-diameter support columns (pillars) with attractive vertical flutes. Their storage capacity ranges from 200,000 gallons to more than 4,000,000 gallons.

- CB&I also designs and builds composite elevated tanks (CETs) that combine the tensile strength of steel with the compressive characteristics of concrete. CETs are cost-effective, long-lasting tanks that feature solid, flush threshold steel doors and internal access ladders for added security and safety. They can be provided with an interior control room and additional space that can be used for offices, fire stations, and other facilities.

50-gallon rain barrel with design advantages

In addition to water tanks, CB&I builds reservoirs and standpipes, ground-level tanks that can be built to any capacity and dimension. CB&I-built reservoirs and standpipes are constructed entirely of welded steel, providing leak-free service. Reservoirs have a greater diameter than height, and standpipes have a greater height than diameter. These tanks have ranged in capacity from under 1,000,000 gallons to 34,000,000 gallons.

CB&I’s experience and inventiveness can be illustrated by the engineering, fabrication, planning, staging, and construction of a steel standpipe provided for the City of Darien, Illinois. With a diameter of 44 feet and an overall height of 153.7 feet, it has a capacity of 1.5 million gallons. The entire structure is composed of 350,000 pounds (175 tons) of steel and uniquely designed to look like a working lighthouse. Its aesthetics are enhanced by a unique coned roof, five pilasters, two balconies, and 10 three-dimensional simulated and machined windows. The balconies and pilasters are not just decorative—they support and hide cell antennas and associated cables. The actual construction required as much innovation as the design. The construction site was extremely tight with an almost complete lack of lay down areas, requiring the tank to be built entirely from the ground level starting with the roof and jacking each shell ring into place as the structure advanced skyward. As the standpipe was jacked up, the balconies and pilasters were installed on the appropriate segments. This structure was named the 2007 Tank of the Year in the standpipe steel tank category by the Steel Tank Institute/Steel Plate Fabricators Association.

The Xerxes Corp. is an industry leader in the design and manufacture of fiberglass storage tanks for the petroleum, water/wastewater, and chemical markets. Xerxes and its parent company in Canada, ZCL Composites, are North America’s largest manufacturer of underground fuel tanks, giving them an extensive history in supplying high-quality fiberglass storage vessels. Underground tanks are designed to withstand H-20 highway loads and are available in sizes from 600–60,000 gallons and in single wall and double wall models. In the field of water conservation, Xerxes provides a wide range of underground and aboveground water storage tank sizes for rainwater harvesting, stormwater management, graywater recycling, chiller unit water collection, and numerous other water storage applications. Green Building projects that incorporate Xerxes fiberglass water tanks may qualify for points under the US Green Building Council’s Sustainable Sites and Water Efficiency categories of its Leadership in Energy and Environmental Design (LEED) rating system. Their fire protection tanks can be used as a standby supply to supplement a pressurized municipal water system or as a cistern for water storage as part of a dry hydrant design. These tanks can serve as a sole source of water in remote rural areas or to augment firefighting water supplies for specific buildings. Fire protection tank applications such as these are recognized system designs found in NFPA 22 and NFPA 1142 fire protection standards. Xerxes also provides unique NSF 61 listed potable water tanks. These tanks not only utilize NSF-approved materials; they also carry an NSF label, which requires NSF inspections of Xerxes manufacturing facilities.

One of Xerxes’ more diverse water tank applications became an integral part of a fire safety system at a rural church camp, after a devastating fire swept through Creek County, northwest of Tulsa in 2012. Located in the countryside far away from a municipal water source, the church camp needed its own fire protection reservoir. Xerxes’ latest tank model, a vertical storage tank design, was chosen for the rebuilding effort. The tank measures 10 feet in diameter and has a capacity of 8,000 gallons. It meets the manufacturing and operating requirements of NFPA 22. The tank serves as a dedicated source of fire fighting water for the sprinkler system installed in the church camp’s new building. Operational flexibility is provided by direct connections that supply water to fire trucks responding to a future emergency.

Tank Connection (TC) is the only company worldwide that designs, manufactures, and installs all types of steel tanks for water storage applications. The best features of bolted and field-welded construction have been combined together in their RTP (rolled, tapered panel) tank design. In liquid storage, it remains unmatched in performance in all category ratings, including long life and low maintenance. Bolted RTP construction features exact manufacturing tolerances with sidewall thickness up to a 1/2-inch plate. No

external reinforcement webbies/web stiffeners are required on their design. TC bolted panels are coated with a proprietary coating system called LIQ Fusion 7000 FBE. LIQ Fusion is the ultimate coating system developed for bolted tanks storing water and wastewater. It is unmatched in performance globally and is a stronger system than glass/vitreous enamel coatings for water storage. TC bolted tanks are constructed in the field utilizing a synchronized, hydraulic screw jack process, which keeps field crews on the ground. This field construction process receives the highest industry ratings for quality control and safety in the field (EMR .6). Bolted liquid tanks are available in sizes up to 8 million gallons. Field-weld construction for liquid storage is available in sizes up to 25 million gallons. TC is also a premier manufacturer of aluminum geodesic dome covers utilized to cover all types of liquid containment applications.

Reservoirs, Ponds, and Liners

Aboveground structures, such as towers and standpipes, are usually augmented by aboveground or belowground service reservoirs. Less common, but considerably larger than water towers are man-made impoundments such as reservoirs that are lakes and ponds specifically created for water storage. These facilities are typically formed by earthwork structures such as berms and dams. Construction of a dam at the low end of a river valley will create an impoundment behind the dam that serves as a water storage reservoir. In addition to impoundments, reservoirs can be created by excavation of ponds below grade, bankside reservoirs constructed to store water pumped or siphoned from an adjacent river, and underground reservoirs utilizing natural caverns or man-made caves. Service reservoirs hold completed treated potable water (strictly speaking, a water tower is a service reservoir).

Florence, CO

As mentioned above, not every water storage structure needs to be made of concrete or steel. Large-scale water storage facilities can be built to resemble natural ponds and lakes. These types of reservoirs require impermeable liners to prevent water losses from leaks through the bottom. All reservoirs need to be lined to prevent loss of water via leakage through the bottom or its embankment sides. Traditionally, this liner is made of puddled clay or rolled clay. More modern reservoirs utilize impermeable geomembrane liners constructed of welded sheets of high-density polyethylene (HDPE), polyvinyl chloride (PVC), and reinforced polyethylene (RPE).

BTL Inc. pioneered the development of heavyweight RPE geomembrane liner products in the 1980s. They have the facilities and capabilities to create the largest panels in the industry, in excess of 150,000 square feet. Their product applications include recreational pond and lake liners, energy industry liners, ranch and farm tarps and liners, environmental covers, pits and conservation applications, commercial containment liners, waterscape projects, stormwater containment, and hazardous liquids containment. Their floating covers (placed on top of lagoons, ponds, or tanks as floating tank covers) reduce evaporation, reduce fumes and odors, allow for containment and collection of gasses, provide thermal insulation for liquids, protect against contamination, isolate liquids from precipitation, and provide security against vandalism or natural wildlife. Their stormwater containment applications (stormwater harvesting, stormwater attenuation, stormwater retention, and rainwater retention) provide strong and dependable impermeable liners that provide watertight systems on a large scale.

Highland reservoir

For sheer size, it’s hard to beat BTL’s installation of an irrigation reservoir in the western United States. Covering 40 acres (equivalent to 36 American football fields), the reservoir provides water for the surrounding farmland, providing insurance against drought. BTL’s unique ability to create extremely large heavyweight reinforced polyethylene liners allows for rapid installation with minimum seaming required. Reducing the number of seams improves the performance of the entire liner system by minimizing the potential for leakage. The entire system was installed in only four days. The reservoir is designed to capture rainfall runoff during the wet season for irrigation during the dry season. This frees the local farmers from dependence on dwindling aquifers and distant natural lakes and rivers.

As the reservoir fills with rainwater and gets subsequently emptied by irrigation, its water level can fluctuate greatly throughout the year. As a result, the liner itself gets repeatedly exposed to weathering, temperature differences, oxygen, and UV radiation—all of which can wear down a liner, breaking its polymer bonds and causing brittle failure. To guard against this degradation of the liner material, BTL has developed a unique, industry-first reinforced polyethylene laminate with an additional 6-millimeter-thick coating of UV inhibitors on the exposed side, the RPEL-30 liner system. This reinforcement provides a full 20-year UV warranty. Physically, the liner installation is protected against tearing, damage, and dislodgement by high winds by a series of ballast liners and sand-filled tubes strategically arrayed from the liner’s edges to its center holding it firmly in place.

The surfaces of moderate-sized reservoirs are also often covered with protective tarps made from the same materials as the liner that have been installed to prevent the entrance of impurities into the stored water. In any case, reservoirs are typically sized to allow sufficient storage time to allow for natural biological processes to remove impurities and the settlement of turbidity.

For large-scale water storage needs, Burke Environmental Products produces both pond liners and covers. Their CSPE/CSM (chlorosulfonated polyethylene) pond liners have been proven by field installations and accelerated aging tests to be a long-lasting solution to water containment. CSPE has superior resistance to weathering, organic and inorganic chemicals, and temperature extremes. Made of a special polymer that has been fabricated in a Thermo-set state, CSPE sheets are created with factory seams made under controlled conditions to maximize strength. The sheets are joined together in the field with seams utilizing wedge welders, hot air welders, and in some cases, high solid-filled adhesives, all of which create a surface cross linking to ensure physical resistance to tear. Each liner is reinforced with one or more layers of woven fabric embedded within several plies of the sheet’s synthetic rubber. Intended for exposed installations, it is highly resistant to sunlight (UV degradation) and weathering.