The presence of air in a pipeline and its impact on operations is probably one of the most misunderstood phenomena in the industry today. Many operational problems are blamed on inadequate thrust blocking, improper pipeline bedding, etc. These problems include broken pumps, valves, and pipes, as well as faulty instrumentation readings. In reality, many of these problems are not caused by improper installation of the equipment but by failure to deaerate the pipeline.

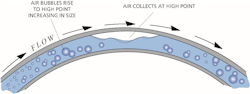

Air in a pressurized, operating pipeline comes from three primary sources. First, prior to start‐up, the line is not empty, it is full of air. To entirely fill a pipeline with fluid, it is necessary to eliminate this air. As the line fills, much of the air will be pushed downstream to be released through hydrants, faucets, etc. But, because air is lighter than water, some will become trapped at system high points. As the system continues operation, this volume of air will continuously be increased by the second and third sources, noted below.

Source number two is the water itself. Water contains approximately 2 percent air by volume. During system operation, the entrained air will be continuously released from the water and once again accumulate at system high points. To illustrate the potentially massive amount of air this represents, consider the following: A 1,000-foot length of pipe could contain a pocket of air 20 feet long if all the air accumulated in one location; a one-mile length of pipe could contain a 100-foot pocket. This would be true regardless of the size of the pipe.

The third source of air is that which enters through mechanical equipment. This includes air being forced into the system by pumps, as well as air being drawn in through packing, valves, etc., under vacuum conditions.

Impact of Air on the System

With the air sources identified, let’s consider the impact it will have on the system. Two problems are apparent. The pockets of air accumulating at high points can result in a line restriction and increased headloss, which can extend pumping cycles and increase energy consumption. The presence of air can also promote corrosion of pipes and fittings.

As air continues to accumulate at system high points, the fluid velocity increases as the fluid is forced through a smaller and smaller restricted pipe area. As the pockets grow, one of two phenomena will occur. The first possibility is a total stoppage of flow. If system dynamics are such that the air cannot be continuously removed by the increased fluid velocity and pushed downstream, then a pressure drop higher than pump capacity can develop, thereby stopping all flow.

The second, and more likely occurrence, is that the increased velocity will cause all or part of the pocket to suddenly dislodge and be pushed downstream. The resulting sudden and rapid change in fluid velocity can lead to a high-pressure surge (i.e., water hammer). Serious damage to valves, fittings, gaskets, or even breakage of the line can occur. This is the most serious of the possible consequences of air being allowed to accumulate in system high points.

Today, most municipalities utilize automatic air valves, which are available in many different designs and configurations for a wide range of applications. Their function is to automatically release and admit air without operator assistance. Air valves are a cost-effective, reliable method of improving efficiency and solving air-related surge problems.

In summary, when air is allowed to accumulate in pressurized pipelines, efficiency is sacrificed and serious damage can occur. A properly deaerated pipeline may not solve all surge problems, but it will address one of the most common causes. WW

About the Author: Diane Meyer is the director of marketing for Val-Matic Valve and Manufacturing Corporation. She also sits on the Board of Directors for the Water and Wastewater Equipment Manufacturing Association (WWEMA). WWEMA is the non-profit trade association representing the interests of water and wastewater technology manufacturers and related service providers. For more information about WWEMA, visit www.wwema.org.

Circle No. 241 on Reader Service Card

About the Author

Diane Meyer

Diane Meyer is the director of marketing for Val-Matic Valve and Manufacturing Corporation. She also sits on the Board of Directors for the Water and Wastewater Equipment Manufacturing Association (WWEMA).