In-Place Rehabilitation of Lead Service Lines

By Amanda Strouse

America’s potable water has been under the public microscope since the Flint, Mich., water crisis began to unfold four years ago. A number of subsequent news articles and investigative reports revealed that the presence of high lead levels in tap water was not limited to the city of Flint, but instead was a massive, countrywide public health issue. The conversation about lead in water became a hot topic and has finally been receiving the attention it deserves.

End-of-run lead sample extracted for Providence Water’s review.

Although precise numbers may be infeasible or impossible to ascertain, the best estimates indicate that approximately one-fifth of Americans over the past decade have been repeatedly exposed to unsafe levels of lead in our country’s drinking water. As citizens have voiced their fears and anger, many municipalities have stepped in to alleviate their residents’ concerns by bringing lead parameters down to safe levels, ensuring their water is safe for consumption.

One such municipality is Providence, R.I. In 2016, the Associated Press reported that it was one of the country’s largest potable water systems to exceed a federal lead standard, with lead levels measuring higher than the limit six times since 2010.

‘‘Our vulnerability is the lead service pipes from the public main to the curb and, even if we fix that, from the curb to private homes,” said Dyana Koelsch, a spokeswoman for the Providence Water Supply Board.1

This brought to light a publicly unknown yet common problem: While there may be millions of miles of large-diameter lead pipes underground that are leaching lead, there are also millions of lead service lines (LSLs) that run from the curbs to homes and buildings. Even if all the lead mains in the country were promptly replaced, the LSLs would continue leaching dangerous amounts of lead.

The in-place epoxy-coating process restored the underground lead service lines while preventing destruction to the landscape above, ultimately saving the historic oak trees.

LSL Remediation Project Uses Modern Technology

In 2016, Providence Water teamed up with pipe coating technology provider ePIPE for assistance with protecting the interior of the LSLs in a neighborhood. This became the first LSL remediation project performed with modern technology in the United States, and ultimately lowered the neighborhood’s lead leaching to safe or nondetectable levels.

Previously-performed traditional repair methods included repipes, which, to the city’s and homeowners’ dissatisfaction, resulted in the removal of historical trees. Providence Water did not want to disturb the century-old houses, their landscaping, or the historical trees on the homes’ properties, which were often located above the lead branch lines.

ePIPE’s in-place method of restoring potable water systems was chosen for Providence’s LSL remediation project because it can be performed quickly, affordably, and with little to no destruction. The epoxy coating is Uniform Plumbing Code-approved for use on metallic and nonmetallic piping systems and is one of the fastest-curing NSF Standard 61- and DWI Regulation 31-approved resins of its kind. It is also supported by multiple patents for bringing lead leaching into U.S. EPA compliance.

A team of skilled ePIPE technicians worked on the 5/8” diameter LSLs from existing curb stops to private dwellings, while a third party handled replacing the LSLs from the mains to the curb stops and installing new curb stops.

The Process

First, by utilizing the existing curb stops, new curb stops and hot air compressors, a sanding agent was blown through the pipes to clean them, remove corrosion and prep the pipes for the epoxy. The sanding agent and any interior pipe debris were blown into a dust collector.

Next, the liquid epoxy was introduced to the pipes at the existing curb stops and was blown through the pipes using compressed air. The epoxy was left to cure for 90 minutes, creating a durable barrier coating on the interior walls of the pipes. Lastly, each LSL was tested and put back into service. All homeowners were provided temporary water during the projects to prevent disruptions to daily life.

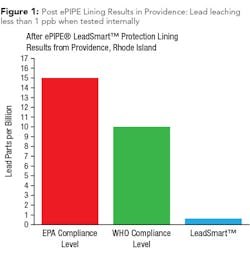

Lead levels before and after the remediation project, compared to EPA and WHO compliance levels.

Results

Independent water tests (following EPA sampling guidelines of a stagnation period of at least six hours) were conducted post-remediation, which showed that lead levels for the homes’ tap water were reduced to less than 1 ppb, which is well below the EPA cutoff level of 15 ppb and the World Health Organization’s (WHO) cutoff level of 10 ppb. This brought the lead levels into compliance, which pleased Providence Water.

Data from the partnership project between Providence Water and ePIPE helped to form part of the Water Research Foundation (WRF) Report 4351, released in March 2017 (the report was jointly funded by the WRF and the EPA). The report recommended coating LSLs as an alternative to replacing them, as replacement can be an expensive, time-consuming and disruptive process.

Cost-effective plumbing restoration technologies like this and others can help U.S. municipalities reduce lead leaching to safe levels, improve existing U.S. infrastructure, keep costs at bay and minimize destruction. WW

About the Author: Amanda Strouse is on the marketing and public relations team for ACE DuraFlo, the creator of the patented ePIPE epoxy coating system.

References

1. “Providence one of largest US water systems to violate lead standards,” Boston Globe (online), April 9, 2016.

Circle No. 302 on Reader Service Card