Smart Monitors Result in Big Savings for Punta Gorda

The Punta Gorda water treatment plant (WTP) is a 10 MGD surface drinking water facility located just east of Punta Gorda, Fla. The treatment process includes floc tanks, four Solids Contact Units (SCUs), which are a form of upflow clarifier that then feed two Greenleaf Filters with four cells each. The filters are backwashed every 70 hours regardless of head loss. High backwash flow rate is 5,200 gpm. The total cost to treat 1,000 gallons of drinking water is $1.73.

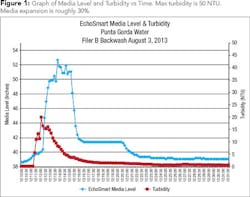

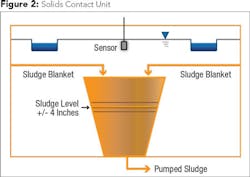

During a field trial with ATI’s FilterSmart Media Level and Turbidity Monitors, it was noted that the loading in the filters was very light (see Fig. 1). Since the backwash schedule was based on time and not head loss, the suggestion was made to incrementally increase the Filter Run Times (FRTs) until the head loss value was reached. FRTs were increased to 120 hours, resulting in a 42% decrease in backwash water consumption annually at a value of approximately $65,000.

Once the instruments were purchased and installed, backwash data also indicated that the high rate portion of the backwash was longer than necessary and was reduced by four minutes. This adjustment resulted in a savings of approximately 22,100 gallons of wash water per wash at a value of $21,000 annually.

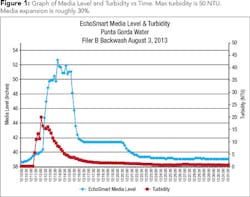

The flow of water in the SCUs is up through a blanket of sludge and into collection pipes that send the water to the filters. The sludge blanket rises to a level where it cascades into a trough, from which it is pumped to the drying process (see Fig. 2). An EchoSmart sludge blanket monitor was installed in each of the four sludge troughs, with the signals used to control the sludge pumps. The goal was to keep the sludge level in the troughs within a 6- to 8-inch range. Previously, the sludge pumps were turned on and off manually, which produced inconsistent results. Using the EchoSmart blanket level to control the pumps eliminated these inconsistencies and greatly reduced the hydraulic loading to the sludge drying train.

Perhaps the most unexpected and significant savings came from the sludge drying process. Backwash water and the sludge from the SCUs first go to a decant tank where the sludge settles and the supernatant is returned to the headworks. The settled sludge goes to one of a dozen three-walled drying cells with underdrains. A layer of sand is spread in the cells to protect the underdrain from the action of the front-end loader. Previously, all 12 cells were needed. With the reduced hydraulic loading, only one or two cells are now needed. Consequently, the amount of sand has been greatly reduced. All told, the savings to the plant in the first couple of years after installing the FilterSmart and EchoSmart monitors could easily reach over a half million dollars.

ATI-Entech Design is a manufacturer of quality sonar interface detection instruments. For more information, visit www.entechdesign.com.