1-2 Punch takes out 1,4-Dioxane on Long Island

Communities on Long Island, New York, almost exclusively rely on groundwater as the drinking water supply. Although groundwaters are typically considered to be a clean source with reduced levels of pathogens, United States federal regulations require that water utilities routinely monitor and report any biological or chemical contamination above regulated limits, referred to as the maximum contaminant level (MCL). Contamination above established MCL guidelines may require treatment to achieve and maintain regulatory compliance.

A contaminant of significant concern in Long Island groundwater is 1,4-dioxane. This compound does not have an established federal MCL in the United States, and if detected, treatment is not mandatory. However, the United States Environmental Protection Agency has classified 1,4-dioxane as “likely to be carcinogenic to humans.”

As early as 2010, drinking water providers on Long Island became aware of 1,4-dioxane in local aquifers and began discussing possible treatment technologies, but little was known at the time about the extent of the contamination. In 2012, EPA released its third Unregulated Contaminant Monitoring Rule (UCMR3), requiring public water systems (PWS) across the United States to monitor for 28 contaminants, which at the time were not covered by federal MCL regulations and did not require routine monitoring. 1,4-dioxane was on this list. On Long Island, data indicated that approximately 70 percent of groundwater wells for public supply contained 1,4-dioxane concentrations above the minimum reporting limit of 0.07 parts-per-billion (ppb). This was likely the result of improper chemical disposal by various industries. Furthermore, approximately 25 percent of UCMR3 tests showed levels above 0.35 ppb, the concentration the EPA considers to be a 1-in-1,000,000 cancer risk in drinking water.

The properties of 1,4-dioxane include a low molecular weight and high solubility in water. This allows rapid solvation and longevity in groundwater aquifers. Water utility personnel on Long Island have spent the last decade studying, quantifying, testing, and installing treatment solutions to remove this contaminant.

UV AOP

A heterocyclic ether, 1,4-dioxane is has been employed as a chemical stabilizer, often in combination with various volatile organic compounds (VOC), most notably species of trichloroethylene (TCE) and trichloroethane (TCA). These chemical contaminants have established federal MCLs and monitoring requirements. Accordingly, Long Island water utilities implemented cleanup methods for TCA at locations where it was detected. Granular activated carbon (GAC) filtration has been common for TCA removal due to ease of equipment installation and operation, and the ability of the media to adsorb a broad range of chemical contaminants. However, GAC is not effective in removing dioxane. Prior to 2008, the analytical detection limit for 1,4-dioxane was 3.0 ppb, much higher than the EPA’s recommended reporting limit of 0.07 ppb. But with modern analytical capabilities, Long Island water providers confirmed observations from others that GAC filtration is much less effective at adsorbing 1,4-dioxane than other VOCs. This has been attributed to the high solubility of 1,4-dioxane, which is why it remains in the water.

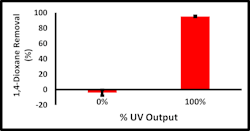

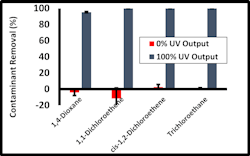

The Suffolk County Water Authority (SCWA) was the first utility on Long Island to investigate an advanced oxidation process (AOP) utilizing hydrogen peroxide in combination with ultraviolet (UV) light to reduce 1,4-dioxane concentrations. UV AOP breaks the chemical bonds of organic chemicals, as opposed to GAC that adsorbs but generally does not alter the chemical structure. Tests began with a small pilot unit at SCWA’s Commercial Boulevard pump station in 2012. UV light introduced within a pressurized steel chamber dissociates injected hydrogen peroxide (H2O2) into highly reactive hydroxyl radicals. These radicals have an extremely high oxidation potential, and can attack many organic compounds, including 1,4-dioxane. The pilot program treated up to 200 gallons per minute (GPM) of groundwater and exhibited greater than 1-log (90 percent) 1,4-dioxane removal at H2O2 concentrations of 2 ppm and above (Fig. 1). The pilot also showed effective removal of other VOCs, including TCA (Fig. 2).

Installation and Subsequent Regulatory Approval

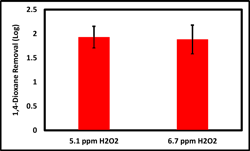

After the successful pilot testing of UV AOP, full-scale design became the next step. The result was installation of a TrojanUVPhox®72AL75 system to treat a maximum flow of 1,100 gpm. A 1.7-log (approximately 97 percent) removal of 1,4-dioxane was guaranteed. The unit was installed in 2016, with follow-up performance verification (Fig. 3). The results exceeded 1.7-log dioxane removal, and subsequently, the New York State Department of Health (NYSDOH) officially approved UV AOP technology as the Commercial Boulevard site’s 1,4-dioxane treatment process at the start of 2018.

Growth at Multiple Groundwater Extraction Sites

In late 2018, a Drinking Water Quality Council established by the NYSDOH recommended a state-wide enforceable 1,4-dioxane MCL of 1 ppb that was made law in the summer of 2020. This law mandated that all water providers in the state monitor for 1,4-dioxane and, when routinely detected at concentrations above the MCL, incorporate treatment. Data from the UCMR3 revealed that 20 different PWSs in New York State had 1,4-dioxane levels above this MCL. Additional data from the UCMR3 indicated MCL exceedance for 56 separate well sites on Long Island.

Per the results from the Commercial Boulevard project, other Long Island water suppliers began to adopt full-scale UV AOP. The Bethpage Water District in Nassau County became the second utility on Long Island to install a full-scale UV AOP system at its Plant #6 well site. This application was more challenging than Commercial Boulevard because it required removal of over twice the amount of 1,4-dioxane. Designed for 3.89-log (99.98 percent) 1,4-dioxane removal, the system has four times the embedded UV output. The process was approved by the NYSDOH and commissioned in 2019.

Further testing and installation of UV AOP technology continued in Nassau County, with the critical first step being quantification of important water parameters that can influence UV AOP performance, including nitrate, UV transmittance (UVT), and scavenging term.

Over 500 water samples from more than a dozen different utilities in Nassau County exhibited high variability in these parameters. For example, nitrate concentrations had a standard deviation of greater than 60 percent from the average value of 20.5 ppm. Similarly, the variation in the scavenging term was 70 percent. The parameter that showed the most consistency was UV transmittance (UVT) with only a 4.3 percent standard deviation. These results highlighted the need for site-specific water analyses and additional pilot testing as a prerequisite for full-scale UV AOP design. Parameters critical to UV AOP performance exhibited both significant regional and seasonal variability across even the relatively small geographic area of Nassau County.

Final Design and Full-Scale Installations in Nassau County

The UV chamber at the Bethpage Water District Plant #6 site had a Z-shaped configuration. In this design, the lamps are installed parallel to the water flow. This layout doubles the required building space, as electrical connections and maintenance access for the lamps are only available from the ends of the chamber. To overcome space constraint issues at other, smaller sites on Long Island, side access to the UV chamber was a necessity. Therefore, a UV chamber with an in-line design with lamps situated perpendicular to the water flow became the design for these other installations. Additional enhancements included UV lamps with twice the output, thus reducing the total lamp count by 50 percent. These features collectively lowered the footprint of the new systems by over 35 percent.

Procurement of the new systems began in late 2019, and the first full-scale installations occurred in Nassau County in early 2020 at multiple well sites of the Bethpage Water District, Hicksville Water District, and Plainview Water District. Commissioning and performance testing was required at each site for subsequent NYSDOH approval to distribute water to end-users. Plant #5 at the Bethpage Water District was the first facility to achieve this milestone, receiving its permit in the summer of 2020, just at the time the NYSDOH finalized its 1,4-dioxane MCL. In total, over 40 full-scale installations are expected across Nassau County by the end of 2021. These facilities will have the capacity to remove 1,4-dioxane from over 50 million gallons of water per day.

Conclusion

The efforts undertaken on Long Island to detect, quantify, and mitigate the threat of 1,4-dioxane in local drinking water has been a decade-long process requiring multiple stakeholder involvement including water utilities, regulatory agencies, numerous consultants and technicians, and technology experts. Through these efforts, Long Island has successfully managed the 1,4-dioxane regulations established in New York State and UV AOP technology continues to be among the best available groundwater remediation technology for 1,4-dioxane and other groundwater contaminants such as TCE and TCA. WW

About the Author: Scott Bindner is a market analyst with Trojan Technologies. He can be reached at [email protected].

About the Author

Scott Bindner

Scott Bindner is a market analyst with Trojan technologies. He can be reached at [email protected].