The Maine Approach to Trihalomethanes

Water District Uses Online THM Analysis to Optimize Operations, Resolve Compliance Concerns

By Craig Douglas

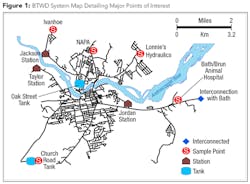

Serving the communities of Brunswick and Topsham in Maine since 1903, the Brunswick & Topsham Water District (BTWD) operates three facilities — Jackson Station, Taylor Station and Jordan Station — to meet the needs of approximately 30,000 residents. All three facilities treat groundwater but each station has a different treatment technology to treat the source water.

In May 2016, due to concerns over decreasing demands and increasing annual running averages of trihalomethanes (THM) in its distribution system, BTWD installed an online THM analyzer to help monitor for these contaminants.

From 2016 through 2017, the district conducted two years of daily online samples from the primary treatment facility, Jackson Station, a 3.5-million-gallon-per-day, intermittently regenerated greensand treatment facility, as well as weekly “grab” samples from representative points in the distribution system. The study provided insightful data about the district’s operational changes and its effect on THM mitigation. The use of an online THM analyzer proved to be a valuable tool, enabling the district to optimize operations, better understand treatment processes, resolve THM compliance concerns, and validate laboratory performance and results.

In 2015 and into 2016, BTWD experienced a THM event threatening regulatory exceedance of total trihalomethanes (TTHM) levels in the Stage 2 Disinfectants and Disinfection Byproducts Rule (Stage 2 DBPR) at the Jackson Station primary treatment facility.

District Operations

BTWD manages close to 120 miles of water mains. One-third of the system is north of the Androscoggin River in Topsham and two-thirds is south of the river in Brunswick (see Fig. 1). Water demand is distributed evenly across the system and BTWD maintains two river crossings between the communities. Because Jackson Station accounts for more than 50 percent of the district’s production, water typically flows from the Oak Street Tank to Topsham and limited portions of Brunswick.

In 2015 and into 2016, BTWD experienced a THM event threatening regulatory exceedance of total trihalomethane (TTHM) levels in the Stage 2 Disinfectants and Disinfection Byproducts Rule (Stage 2 DBPR) at the Jackson Station. Although the event was ultimately identified as a laboratory analysis error, in response to the event and before the cause of the exceedance was identified, the district began conducting weekly grab sampling at four distribution sites (Ivanhoe, NAPA Auto Parts, Lonnie’s Hydraulics and Church Road Tank) to monitor THM levels from May 2016 through December 2017. Daily online samples were also taken at the treatment facility and provided several daily snapshots of THM levels entering the distribution system.

BTWD installed an online THM analyzer, the THM-100™ manufactured by Aqua Metrology Systems, at the Jackson Station facility in May 2016 to assist with the ongoing investigation. The automated system uses a “purge-and-trap” method for TTHM extraction of the sample, followed by desorption into a chemical mixture that generates a colored product and time-resolved spectrophotometric analysis for detection and determination of THM levels.

In addition to the online samples, manually collected grab samples from other locations in the network were collected and analyzed alongside samples taken automatically by the monitor in its online mode. On average, the THM-100 analyzes six online samples daily and five grab samples per week. The analyzer provided THM data at a fraction of the cost and time compared to traditional methods, ranging from $7-$14 per sample and providing results in 90 minutes. This allowed for analysis not only at Jackson Station but also throughout the distribution system.

Sampling Protocol

BTWD was specifically interested in three sample locations: Ivanhoe, NAPA Auto Parts and Lonnie’s Hydraulics. These sites receive water age ranging from three to seven days depending on the cycles and demands of the water system, with younger water typically coming directly from Jackson Station and older water typically associated with the system’s storage tank.

BTWD developed a sampling protocol to ensure that the sample sites adequately turned over water. The district also considered system demand and THM precursor variations and their impact on distribution THM readings.

The Ivanhoe and Lonnie’s Hydraulics sites are mainly residential neighborhoods influenced by outside watering and vacations that can vary system demands. NAPA Auto Parts, located in a predominantly commercial area, is influenced by the seasonal water demands of the regional middle school, which is the last customer before the sample point.

Well selection and groundwater hydrology were examined in more detail to determine their impact on THM formation. To aid in this review, the online analyzer was set up to analyze samples directly from the first customer in the distribution system. During plant operation, the analyzer would measure the TTHM levels at the end of the contact chamber, and during plant shutdown it would monitor flows heading back from the storage tank to the Ivanhoe sampling point.

Data Collection and Analysis

BTWD reviewed data points collected when the treatment plant was in operation. This data was then overlaid with well pumping data from the Air Force and Holden wells, which supply Jackson Station and are swapped on a biweekly basis. The data clearly depicted that the biweekly well switch had a significant impact on THM levels leaving the facility. The wells are in a semi-confined aquifer and the recharge mechanisms for the confined portions are slower and likely correlate to older groundwater, whereas the younger groundwater is likely recharged by surface waters.

Using the online THM analyzer, BTWD created THM system distribution simulation (THM-SDS) curves using production water. The THM-SDS curves were produced for each well source at day zero and day seven after the biweekly well change. These results supported the idea that the Air Force and Holden wells influence each other by shifting the zones of influence and subsequently the zones of contribution.

In early 2017, BTWD undertook a six-month pilot project to investigate new treatment techniques for the supplies at Jackson Station. The district ran the Holden well for two months, 24 hours a day. The online THM data from online and grab samples collected during this period (January and March 2017) indicated far more stable THM formation relative to the biweekly swapping of wells.

Lessons Learned

Until the online THM analyzer was installed, the data available were insufficient and the district was unaware of the significant fluctuations in THMs leaving Jackson Station. In this instance, the source of the fluctuation appeared to be the movement of the zone of contribution between the two production wells, which resulted in initial periods of high or low TTHMs.

Although BTWD’s research into the effects of well swapping and the creation of the THM-SDS curves left the district with a healthy questioning of what it can forecast within the distribution system, especially given the intermittent operation of the Jackson Station treatment facility, BTWD was nevertheless able to make some operational decisions based on the data collected in the field.

The district learned a significant amount of information from the samples processed by the online THM-100 analyzer. The data collected over the two-year THM monitoring study not only revealed a laboratory analysis error but also helped BTWD study and better understand supply and distribution management impacts on THMs, evaluate its analytical results and build the district’s confidence in the data collected. It also helped the district address its THM compliance concerns and optimize operations.

About the Author: Craig Douglas, P.E., is the assistant general manager for the Brunswick & Topsham Water District.

Circle No. 252 on Reader Service Card