Program Studies Industrial Compliance with Stormwater Rules

By Robert Naeser

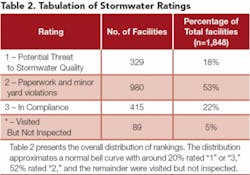

Activities such as material handling and storage, equipment maintenance and cleaning, industrial processing or other operations that occur at industrial facilities are often exposed to stormwater. The runoff from these areas may discharge pollutants, such as toxic metals, oil, grease, and other chemicals, directly into nearby bodies of water or indirectly via storm sewer systems, thereby degrading water quality.

To minimize impacts from stormwater, the U.S. Environmental Protection Agency (EPA) developed permitting regulations under the National Pollutant Discharge Elimination System (NPDES) to control stormwater discharges associated with 11 categories of industrial activity. As a result, NPDES permitting authorities, which may be either EPA or a state environmental agency, issue stormwater permits to control runoff from these industrial facilities.

Industrial facilities subject to these stormwater permits are generally required to develop and implement a stormwater pollution prevention plan (SWPPP) including best management practices (BMPs) to control stormwater. In addition, many states require monitoring of stormwater discharges to ensure that the facility’s SWPPP is effective. To help assess whether industrial facilities are complying with their stormwater permit requirements, the California State and Regional Water Quality Control Boards and U.S. EPA Region 9 contracted with Tetra Tech Inc. to conduct compliance inspections at industrial facilities across the state.

Between August 2001 and May 2005, Tetra Tech conducted industrial stormwater compliance inspections at 1,848 industrial facilities subject to California’s General Permit for Stormwater Discharges Associated with Industrial Activity (CAS000001, 97-03-DWQ [General Permit]). To streamline the reporting process and assist in summarizing inspection results, Tetra Tech developed a General Permit inspection database. The database tracks facility compliance with all required General Permit components including: stormwater pollution prevention plan (SWPPP); stormwater monitoring program (SWMP); stormwater monitoring results; and implementation of BMPs.

Industrial Facilities Inspected

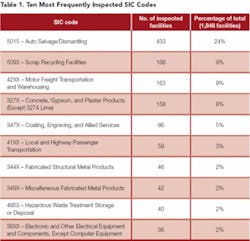

California’s database of facilities covered by the General Permit contains 9,543 facilities. Based on this number, Tetra Tech inspected approximately 19% of the regulated community, including facilities representing more than 124 different SIC codes.

Inspection Results

Compliance with paperwork requirements

The General Permit requires facilities to have, and maintain on-site, a SWPPP, SWMP, historic annual reports and monitoring data. Annual reports and monitoring data must be retained for a period of five years (or from when the NOI was submitted, if less than five years). Reviewed SWPPPs and SWMPs ranged from professionally prepared to handwritten documents.

SWPPPs

Under the General Permit, the SWPPP is the primary regulatory document governing the facility’s stormwater program. It must include a facility map, discussion of significant materials and quantities stored at the facility, and a discussion of stormwater BMPs that will be implemented to minimize the mobilization of pollutants in stormwater, among other requirements.

Seventy-four percent of inspected facilities produced a document identified as a SWPPP. The other 26% either had not written a SWPPP or claimed that it was located at an off-site location or was at the consultant’s office being updated. However, less than half of the SWPPPs produced for Tetra Tech inspectors met all General Permit requirements.

The SWPPP BMP list seemed to present the most problems. Frequently, the SWPPP provided a general list of BMPs for a specific industry, found on the Internet or obtained from an industry group, regardless of whether or not the individual BMPs were appropriate to or implemented at a specific facility. A common example is “yard will be swept on a daily basis” when the yard surface is, in fact, dirt. Technically, an enthusiastic inspector could consider a facility out of compliance for each BMP listed in the SWPPP, whether appropriate or not, that was not implemented in the yard. Facility representatives should carefully evaluate the BMP list prior to certifying the SWPPP to verify that BMPs listed are appropriate to their facility.

Also, facility representatives should ensure that their SWPPP is always available on-site, not only for the EPA inspector but also for facility staff to use to ensure BMPs are implemented properly.

SWMP Compliance

Not all states require a separate stormwater monitoring program document; some states require the monitoring program to be described in the SWPPP. In California, the SWMP describes the facility’s approach for visual observation of stormwater discharges, analytical sample collection, constituents for which analytical analysis is required, analytical methods, and observation frequencies.

Sixty-seven percent of inspected facilities produced a SWMP; however, unlike the SWPPPs where only 48% met all General Permit requirements, 87% of the SWMPs met all General Permit requirements. The different levels of completeness between SWPPPs and SWMPs were surprising. Results suggest that if a facility has a SWMP, it is likely to be complete. A possible reason for this is that SWMPs are largely boilerplate and the information, with the exception of sampling locations, can be reliably obtained from the General Permit, Internet, or from another facility in the same SIC code.

Sampling and Monitoring Results

Visual and analytical stormwater monitoring is required by the Permit unless the facility did not discharge during any of the storm events or the storm occurred outside of normal business hours. Data must be maintained and submitted with each year’s annual report, due in July.

In California, stormwater samples must be analyzed for four standard parameters: total suspended solids (TSS); pH; specific conductance (SC); and total organic carbon (TOC). Oil and grease (O&G) may be substituted for TOC. Specific SIC codes are required to perform analytical tests for additional pollutants, as discussed in CAS000001 Section B, Table D. Analytical results are submitted with each year’s annual report for comparison against “benchmark values.”

EPA has set benchmark values for selected parameters to help facilities assess whether their SWPPP and BMPs are effective. Sample results above benchmark values, or outside benchmark values in the case of pH, are not considered to be General Permit violations because the benchmark values are guidelines rather than effluent limitations. Moreover, concentrations outside benchmark values are considered to be indicators of inadequate stormwater BMP implementation.

For the 1,848 facilities inspected by Tetra Tech, the following stormwater analytical data results were found:

- 1,424 facilities (77%) collected the required number of samples;

- 873 facilities (47%) reported exceedances of one or more benchmark values in one or more sample events;

- 1,615 individual sample results from these 873 facilities reported analytical results outside of benchmark values for one or more of the following parameters: pH; TSS; SC; O&G; and TOC.

Review of the 1,615 individual analytical stormwater monitoring samples determined that:

Available analytical monitoring data suggests that specific conductivity and total suspended solids are the two parameters most likely to be outside of benchmark values. The frequency of elevated specific conductivity, a measure of total dissolved solids and salinity, suggests that this parameter may not be easily controlled through good housekeeping and other traditional BMPs.

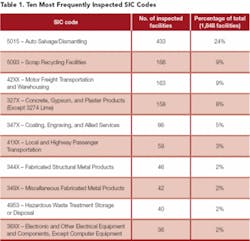

Distribution of Facility Stormwater Ratings

To help the State and EPA quickly identify priority facilities for reinspection, Tetra Tech assigned an overall rating to each facility inspected based on the types of potential violations observed:

1 - Poor stormwater BMP implementation and management practices present a threat to the quality of stormwater discharged from the facility.

2 - Compliance issues with required General Permit paperwork requirements and minor yard issues. Facility is not deemed to be a threat to stormwater quality at the point(s) of discharge.

3 - Facility determined to be in compliance.

In general, the category 1 facilities were prioritized for immediate reinspection by the state. Category 2 facilities could be adequately addressed through a letter or notice from the state, but did not necessarily warrant a reinspection. Category 3 facilities were in compliance with all requirements, and did not require any follow-up.

Conclusions

Industrial facility operators can learn from these inspections by ensuring that:

- The SWPPP is always on-site. Facility representatives should be trained and familiar with the contents of the SWPPP, requirements in the General Permit, and implementation of SWPPP BMPs.

- The SWPPP is reviewed and updated on a regular basis to ensure that BMPs implemented in the yard are reflected in the SWPPP, and vice versa.

- Monitoring data is reviewed and when a parameter exceeds the benchmark value, then BMPs and the SWPPP are assessed to determine whether changes are needed.

- Monitoring data is compared across years to determine whether the facility’s stormwater performance is improving or declining.

Overall, the inspection process provided benefits to the regulators and the regulated community. Regulators were surprised that less than 20% of the facilities fell into category 1. With this information, the regulators are working on strategies to identify and target potential category 1 facilities for inspection. Communication between the regulated community and regulatory representatives resulted in compliance assistance and facility representatives often used the inspection reports to request and obtain additional funding for stormwater improvements and program implementation.

About the Author:

Robert Naeser is a Senior Environmental Scientist with Tetra Tech’s Lakewood, CO, office. He currently manages Tetra Tech’s compliance inspection program for USEPA Region 9 and the State of California, including more than 200 NPDES wastewater compliance evaluation inspections and at least 150 industrial stormwater inspections annually.

Notes

- Additional information on EPA’s industrial stormwater program is available at http://www.epa.gov/npdes/stormwater.

- Information on California’s industrial stormwater program, including a copy of the general permit, is available at http://www.waterboards.ca.gov/stormwtr/industrial.html.