Largest MSF units to operate at Shuweihat

By: Roberto Borsani

Desalinated water is scheduled to flow from the world's largest multi-stage flash (MSF) facility in Shuweihat, UAE, by October 2003. Financial closure, which transpired last December, assures all parties involved in the US$ 1.6 billion project, that the largest IWPP (Independent Water Power Producer) for Phase 1 will be funded.

The Shuweihat Project Company, comprised of the Abu Dhabi Water Electricity Authority (ADWEA), US-based CMS and International Power of the UK, will build and operate a 1,500-mW power and 100-million imperial gallons per day (migd) desalination plant. The company will provide special facilities, such as the 400kV and 220 kV grid stations and the 120-migd water pumping station, which will be operated by the local transmission company TRANSCO. The water plant will be provided on a build-own-operate-transfer (BOOT) basis.

CMS/International Power signed in December 2001 a US$ 895 million EPC contract with Siemens and a US$ 500 million contract with FisiaItalimpianti.

The consortium between Siemens of Germany and FisiaItalimpianti of Italy will construct the power and desalination plant to begin partial water production by October 2003 and complete production by August 2004. Two UK consultancies, PB Power and Mott MacDonald Ltd, will ensure that technical standards are met to satisfy project specifications and financial lenders, a consortium of regional and international banks.

The Power Island is a combined cycle system that includes five large gas turbines (type V94.3A), each connected with a heat recovery boiler and two back pressure steam turbines, which supply steam for the MSF desalination plant. Two dump condensers will allow independent power and water variation.

Six jumbo MSF distillers constitute the Water Island. Each distiller will produce 16.66 migd of distillate water, which will be remineralised in a limestone dissolution plant and stored in six large steel tanks; a seawater pumping station is also included to provide water to feed the distiller and cooling medium to the power plant. The Shuweihat Phase 1 plant is the first of three identical phases. The next two phases will be constructed in a later stage.

This large-size MSF represents the latest generation of desalination unit that was designed particularly for hard sea water conditions in the Middle East - high salinity above 40 gr/l and temperatures between 30 to 35 °C. Its design is based on successful experience and feedback in the past 10 years from units that produce between 10 to 13 migd.

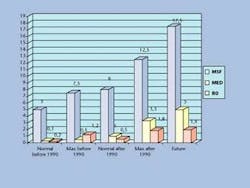

Water production from a single MSF unit has risen significantly from 60 years ago when this technology first appeared in the market. Figure 1 shows a detailed analysis of desalinated unit capacity of different technologies, including MSF, multiple effect (MED) and reverse osmosis (RO).

The first MSF units produced only 2-3 migd but the booming Saudi market in the 1970s helped to standardise the 5-migd size as the most used unit size. The 7.5-migd size was applied widely in the 1980s. The 10- to 12-migd size entered the market in the 1990s. Many experts doubted that such a large unit could be designed and operated properly; however the first large-size units of Al Taweelah B started operating in 1994. The results exceeded all expectations.

• very high production - peak load of 13 migd

• very high performance ratio - always 15% above design

These units remain in operation confirming that operational doubts were unjustified and that MSF technology could be applied in more applications than previously considered.

Another important breakthrough is the 15-migd MSF design, which surpasses the 12-migd design. FisiaItal-impianti recently constructed three 15-migd MSF units as part of the Jebel Ali K Phase 2 project in Dubai, UAE. The units will begin operating in April 2002.

MSF design parameters

The Shuweihat plant, now under construction, is only the first of a three-phase project. Two more identical phases will be awarded in the next five years, which will provide a total of 4,500 mW of power plus 300 migd of water.

Design parameters that characterise the design and performance of the MSF unit are unit production; performance ratio; distillate purity; specific electric power consumption and maximum seawater temperature rise.

Unit production refers to the maximum production that the unit can produce. It is very important to specify the top brine temperature (TBT) and seawater temperature (SWT) at which this production is reached. These parameters normally fix the brine recycle flow and then influence the width of the desalination unit.

Performance ratio is the ratio between distillate produced and steam consumed at a standard enthalpy, which is normally taken as 2,326 Kj/Kg. This is the difference of enthalpy between the inlet steam and condensate returned to the power station. This parameter fixes the best combination between stage numbers and heat exchange surface.

Distillate purity is the salinity of the distillate water, which is produced by the unit and is normally expressed as ppm or is measured as conductivity. This parameter determines the overall demisters area and then influences the height and length of the desalination unit.

Specific electric power consumption is the ratio between electric power consumed by the unit and the distillate produced and is expressed as Kwh/m3/h. Consumers to be specified normally include sea water pump; brine recycle pump; brine blow down pump; distillate pump; and condensate extraction pump.

Maximum seawater temperature rise is the difference between inlet and outlet seawater temperature and from this value the sea water inlet flow is calculated.

Shuweihat Phase 1

The Shuweihat Phase 1 project, which includes the largest MSF desalination unit, represents the best of MSF technology currently available. The seawater pumping station includes trash racks, travelling band screens, hypochlorination plant and 6+1 standby intake pumps, each of 27,900 m3/h capacity.

The MSF desalination units includes six 16.66 migd distillers with process pumps, brine heaters and other auxiliary equipment. The steam supply consists of low pressure steam supply lines and two dump condensers, medium pressure steam lines and condensate return lines.

The discharge outfall includes three ND 2800 and one ND 2660 glass reinforced pipe (GRP) lines and one concrete outfall that will discharge into an outfall system.

The remineralisation plant includes eighteen limestone dissolution vessels and all auxiliaries to potabilise the distillate produced.

Six cylindrical cone roof steel tanks, each with a capacity of 76,000 m3, will store water. A potable water pumping station includes several variable speed pumps to provide forwarding capacity of 120 migd.

Conclusion

Experts forecast that the desalination market is very promising. The actual total installed capacity of desalination plant reached five percent of the overall global water consumption, which confirms that seawater desalination is a strategic way to solve the water scarcity problem. More large desalination plants will be constructed alongside power plants, particularly in the Middle East, to meet rising demands for water and power.

The MSF technology has demonstrated to be the strongest way to produce potable water from the sea in the Middle East region, and the only one that can increase unit size without problems and allow significant saving in installation and operational costs. In contrast, MED and RO, two other desalination technologies, can provide units of a maximum of 5 and 2.5, respectively. For a plant of 100 migd, this means that 40 or 80 units must be installed - clearly an uneconomical way to produce water from seawater in the Middle East.

Author's note

Roberto Borsani is the manager of the Desalination Department at FisiaItalimpianti, based in Genoa, Italy and is director of the International Desalination Association (IDA) since 1994.