Robotic Camera System Eases Smelly Surveillance

Helsinki Water deploys a DigiSewer pipeline measurement/inspection system by Painehuutleu Oy PTV of Finland to aid its sewer rehabilitation programme.

Responsibility for the provision of potable water and sewerage services to Helsinki, Finland (population ~565,000), falls to Helsinki Water, the municipal business enterprise wholly-owned by the city. The utility has served the city in this capacity for over 130 years and currently provides potable water to 910,000 consumers as well as handling sewer services for 810,000 consumers in the capital area.

As part of its ongoing responsibilities, Helsinki Water has decided to do undertake rehabilitation works on the sewer networks. In order to achieve its target for rehabilitation works, it’s required to internally inspect between 150 km and 200 km of sewer pipelines and classify their condition to enable planning of any renovation works that may be deemed necessary. This makes it possible to renew sewage networks at a rate of around 20-to30 km/year, depending on the yearly investment on water network renovation.

Normally, Helsinki Water utilises standard closed circuit television (CCTV) inspection techniques for this work. Over the period from June to August 2007, however, Helsinki Water undertook a significant sewer investigation project, as a pilot, study using a robotic pipeline inspection and measurement system known as DigiSewer®, under the supervision of utility production engineer Sami Sillstén.

DigiSewer is a system that, when surveying the inside of a pipe, generates not only the normal forward view of the pipe wall, as normally achieved by a standard CCTV inspection system, but also a flat, all-round view of the whole 360° of the pipe’s inner wall. The data collected is then automatically analysed to generate highlighted defect information, which is then easily and quickly reviewed in an office environment where it can be used to plan any subsequent rehabilitation operations. The purpose of the recent Helsinki project was to establish how the DigiSewer system could make inspection, site work, analysis, results presentation and ultimately planning of such rehabilitation much easier for the Helsinki Water’s planning engineers.

Acting as both consulting engineer and main contractor for the project, Finland-based Painehuuhtelu Oy PTV, the inspection system provider and operator, was engaged to survey one area of Helsinki’s sewer system covering some 4.5 km in length and including pipe diameters varying between 300 mm and 800 mm. In order to enable Helsinki Water’s engineers to establish the system’s performance whilst surveying different materials, the network section chosen for the survey also included a variety of pipe materials including concrete, PVC and clay. The sewer section chosen was also typical of any sewer network in Finland laid at a depth of 2-to-3 m.

Sewer Inspector

The DigiSewer system is designed to be a fast and reliable PC-based method of measuring the condition of a pipe and storing this information into a digital format. It provides automatic interpretation of condition data collected to a dimensional accuracy of 1 mm using specially designed data analysis software. This makes the actual survey, data collection and interpretation process operator free. This is achieved because the viewing head of the DigiSewer system is designed to scan the whole of the inner pipe wall around its full 360o circumference in the one operation, unlike conventional CCTV which requires operator intervention to reposition the camera head to view defects, laterals and joints during a survey.

Unlike with conventional CCTV survey systems, Painehuuhtelu Oy PTV prefers to refer to a pipeline survey as a condition “measurement” of the pipeline as opposed to an “inspection”. This is because the data collection achieved with the DigiSewer system provides a level of accuracy not possible with conventional systems.

In practice, the operation to realise a digital pipeline measurement and analysis survey looks very much the same as any conventional CCTV survey technique, which is used everyday across the globe. After the pipe is cleaned, the inspection equipment is launched from an accessible manhole and driven inside the pipe requiring surveying. The equipment then runs uninterrupted from one manhole to another. Unlike conventional systems, there’s no need for the camera operator to stop the survey equipment where defects are found, to record positional data and condition notes on screen to aid later analysis. This is because data collected is automatically stored millimeter by millimeter onto a CD as the survey progresses without operator intervention. This also eliminates the slow, live picture observation required during a conventional survey operation as well as reducing, if not eliminating, the potential for operator error and missed defects which might arise during a conventional survey. In addition, the system has an automatic lateral and joint analyser.

The precise information provided by the DigiSewer system makes pipeline information observing and understanding much simpler. Once the survey run is completed the data can be examined using the viewer program, known as the WinScan Viewer, on a PC screen in the office. This viewer program can be installed on several office computers without extra cost. It enables the pipeline analyst/engineer to view a complete manhole-to-manhole survey on the computer screen in one single view. It’s also possible to see five different aspect pictures of one single defect at same time. These include the open view, front view, complete manhole-to-manhole section on a single screen, a graphic drawing of the manhole-to-manhole section showing the plan position of any defect, and the inclination curve of the pipeline between the manholes.

And compared to conventional CCTV surveys, the speed at which the collected data can be reviewed by analysts can be as much as five time faster.

A Roving Camera

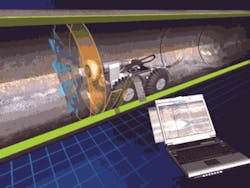

For the Helsinki project itself, the sewer section chosen was first jetted clean with a high pressure cleaning unit, using water jets at up to 170 bar pressure operating at around 380 L/min. The inspection system itself comprised an iPEK-manufactured Rovver camera tractor unit onto which was mounted the DigiSewer “camera”. The survey data was captured and processed using WinCan V8 reporting software.

Work started on the inspection operation on June 29, 2007, with the survey work, officebased analysis and full reporting completed and presented to Helsinki Water by Aug. 8, 2007, or just 5-½ weeks from start to finish for a 4.5 km inspection operation.

The breakdown of the actual survey project timings also was interesting with the pipeline cleaning work taking some 80 hours, or twice as long as the actual survey and data collection work which took just 40 hours. In addition to the on-site pipeline work, there were two further days of work in the office to complete the final analysis of the survey information and prepare the final reports for Helsinki Water. An interesting difference between the data access using the DigiSewer system and a standard CCTV inspection arrangement is that, using the DigiSewer system all of theproject sewer’s 4.5 km length, or some 128 individual files, can be fully viewed in only 4 hours. This compares to around 19 hours using standard VHS data storage, at 700 m of survey per VHS cassette. Or to put it more simply, the DigiSewer data was reviewed in just 1/5th of the time of that for a conventional survey whilst providing condition information to a much higher degree of accuracy.

Having completed the survey and report presentation, Helsinki Water’s planning engineers are in the process of preparing a detailed renovation work programme covering the surveyed pipeline and the defects uncovered by the survey work. Overall, no specific problems were encountered during the work programme and the reports were generated and presented within the expected time frame, with the work being achieved at a cost which equates to less than €5/m.

Conclusion

Commenting on the project for Helsinki Water engineer Sillstén said: “DigiSewer sewer inspection method is the future of this kind of work. In Finland, the sewer networks (about 40,000 km) are reaching the end of their lifespan, so there are huge renovation works that lay ahead. It’s critical to find the order in which these renovation projects are to be done. Key to that is to have comprehensive knowledge of the condition of the sewage networks.” This means massive amounts of data to be handled, which the new system makes simpler than conventional methods, he said acknowledging: “To make our work easier, techniques change and improve and so must we.”

For survey consultant and contractor Painehuuhtelu Oy PTV managing director Sakari Kuikka, said: “From a contractor’s point of view, the DigiSewer pilot project with Helsinki Water has shown our systems to be fast on site and fast in report generation, with a minimum of paperwork, with all data provided on a DVD in the case of the pilot project, 4.4 km, all pictures and condition reports covering 500 pages with summary reports on one disc. From a consultant or rehabilitation/maintenance engineer’s point of view, the results offer flexible and easy to handle access to pictures data and summaries including inclination details, with the whole project being viewable in just four hours because the reporting system makes for relatively small reports.”

The ability to pick out points of interest using digital data and summary reports instead of having to view a whole survey also saves significant time, effort and cost for planning engineers, Kuikka added. These points can be further summarized by the client for a concise picture of where work needs to be done.

Painehuuhtelu Oy PTV a specialist in survey and maintenance of urban and industrial water supply and sewerage systems is based in Nurmijärvi, Finland. Contact: +358 9 290 2230, [email protected] www.painehuuhteluptv.fi