Membranes for Municipal Water and Wastewater Treatment

When it comes to water membrane technology, there are currently four different types of membranes, three of which are frequently used for municipal water and wastewater treatment.

Four Membrane Types

The first two classifications are microfiltration and ultrafiltration. The microfiltration and ultrafiltration processes use low-pressure membranes, either immersed in aeration tanks, using a vacuum system; or in external pressure-driven membrane units, to remove suspended solids. In the latter application, they can replace secondary clarifiers and tertiary filters.

Microfiltration is able to separate particulate from water down to submicron and colloidal size. It is often used upstream of reverse osmosis systems that remove soluble materials from feed water. Ultrafiltration is able to remove even smaller particles, including viruses.

According to Peter Cartwright, president of Cartwright Consulting, there is a difference of opinion with regard to the definition of microfiltration and ultrafiltration. “Some people in the industry base it on molecular cut-off, but I define it based on function. For example, if your goal is to remove suspended solids, then use microfiltration applications. However, if your goal is to remove dissolved micro-molecules [dissolved organic molecules], then use ultrafiltration.”

A third type of membrane utilizes nanofiltration, a membrane filtration process used most often with low total-dissolved-solids water, such as surface and fresh groundwater, with the goal of softening it. Nanofiltration membranes have pore sizes smaller than those used in microfiltration and ultrafiltration and are primarily used in industry (chemicals, pharmaceuticals, etc.), and rarely for municipal water or wastewater treatment.

The fourth type, reverse osmosis, uses a semi-permeable membrane to remove ions, molecules, and larger particles from water designed for drinking or cooking. In addition, rainwater collected from storm drains is often purified with reverse osmosis membranes for use as landscape irrigation and industrial cooling.

“Since the suite of municipal wastewater membrane technologies—which are all cross-flow, pressure-driven membrane separation technologies—are so varied in their capabilities, you usually use at least two of the technologies in every project,” says Cartwright. And, for most wastewater treatment applications, microfiltration and ultrafiltration are the two most common.

Growth of the Technology

“Membranes, of course, have become very important in the last few decades for water and wastewater treatment, because they are highly efficient and require a small footprint,” says Pushpinder Puri, president of PuriMem LLC, which offers consulting services on membrane technology, process research and development, and innovation processes. Services related to membrane technology include microfiltration, ultrafiltration, nanofiltration, reverse osmosis, desalination, membrane bioreactors, and other wastewater treatment technologies. “However, despite how fast the technologies are advancing, the use of the advanced membrane technologies is not growing as fast as it could, primarily because a lot of municipalities in the United States don’t have the financial resources to invest in these new technologies.”

In Europe, though, according to Puri, the infrastructure changes much faster. “In Europe, for example, they use membrane bioreactors instead of septic tanks for individual households,” he says. “Europe has always been a little ahead of the US when it comes to environmental regulation. This is because cities and even rural areas are more congested in Europe, while, in most parts of the US, there is plenty of land and plenty of water.”

According to a June 2016 report, “Global Market Study on Membrane Separation: Water & Waste Water Segment to Witness Highest Growth by 2019,” published by Persistence Market Research, the global membrane separation market (which includes microfiltration, ultrafiltration, nanofiltration, and reverse osmosis) was valued at $19 billion in 2012, and is expected to reach $39.2 billion by 2019, a compound annual growth rate (CAGR) of 10.8%. The anticipated growth will be the result of increasing mandatory government regulations, such as the Clean Water Act; a shift away from chemical treatments, which are perceived as environmentally unfriendly, toward physical treatment; and increasing demand for clean processed drinking water worldwide. And, according to the report, microfiltration dominates the market with more than 35% of global market share in 2012.

Another June 2016 report, “United States Membranes Market by Type, by Application, Competition Forecast, and Opportunities, 2011-2021,” published by TechSci Research, estimates that the domestic membrane market is projected to grow at a CAGR of 8% from 2016 to 2021. In 2015, microfiltration accounted for the largest revenue share in the US membrane market. One reason for the expected growth is the increasing government expenditures of installation and upgrades of water and wastewater treatment plants in order to ensure clean water to the general public and the surrounding environment. In specific, the US municipal wastewater treatment market stood at $7.9 billion in 2014, and is expected to reach $8.4 billion by 2017. “Growth in demand for reverse osmosis membranes is expected to increase at the fastest pace during 2016 to 2021, due to increased adoption of reverse osmosis-based filtration technology by various application industries,” say Karan Chechi, research director for TechSci Research. “Installation of reverse osmosis membranes in water and wastewater treatment has also been witnessing robust growth over the last five years, and the trend is expected to continue over the next five years.”

A January 2016 report on global microfiltration membrane markets, published by BCC Research, which publishes reports on membranes on a regular basis, states that the global markets for microfiltration membranes, which reached almost $1.9 billion in 2015, are expected to increase to $2.6 billion in five years. While most of the current usage and growth are occurring in industrial settings (particularly biotech, bioprocessing, and pharmaceuticals), the drinking water segment is expected to increase from $334 million in 2015 to $474 million in 2020.

Membrane Bioreactor Technology

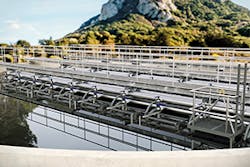

While the four types of water membranes have been around for quite awhile, the technology that seems to be attracting the most attention these days is Membrane Bioreactor (MBR) technology. Though first introduced in the late 1960s, the technology has been becoming more popular in recent years. MBR is the combination of a membrane process, such as microfiltration and ultrafiltration, with a suspended-growth bioreactor that is able to produce effluent of a high enough quality to be discharged into coastal or surface waterways, or also to be reclaimed for urban irrigation.

The membranes can be designed for and operated in small spaces, and offer high removal efficiency of contaminants such as nitrogen, phosphorus, bacteria, biochemical oxygen demand (BOD), and total suspended solids. The membrane filtration system can replace the secondary clarifier and sand filters in a traditional activated sludge treatment system.

MBR technology has gained popularity over the last decade for a number of reasons, including its small footprint, continuing affordability (prices decreasing as efficiencies continue to increase), and the ease of retrofitting in order to upgrade existing wastewater treatment plants.

The technology’s popularity is also the result of increasing water demands, both in terms of the volume of water being required worldwide, as well as environmental regulations requiring increased water purity.

In addition, as concerns over energy efficiency increase, MBR technology becomes more appealing, since the systems can process more water using less energy than other traditional systems.

“MBR technology includes microfiltration or ultrafiltration membranes that are designed specifically to remove suspended solids, biochemical oxygen demand, and fecal coliforms from the treated sewage,” says Cartwright. “MBR is then followed by reverse osmosis, and then by disinfection technology like advanced oxidation—the popular ones being ultraviolet light and hydrogen peroxide—to perform the disinfection treatment.”

Ultraviolet light protects against harmful microorganisms without compromising the taste, color, or odor of water. Ultraviolet light can be used alone or in combination with hydrogen peroxide to destroy pesticides, taste and odor compounds, pharmaceuticals, algal toxins, and industrial contaminants that may be found in water.

“This process is able to produce drinking water,” says Cartwright. “In some cases, though, there is some tweaking. For example, a system may include ultrafiltration pre-filtration to protect the microfiltration membrane and ultrafiltration membrane. And, in some cases, the pH is increased to make the drinking water less corrosive.”

According to Cartwright, if the goal is to remove suspended solids, then a microfiltration application makes sense. However, if the goal is to remove dissolved micromolecules (dissolved organic molecules), then ultrafiltration makes sense. “In fact, since some of the bacteria may be very, very small, the bulk of MBR membranes are ultrafiltration,” he says.

There are a number of MBR configurations for microfiltration and ultrafiltration membranes. The two main ones, according to Cartwright, are plate-and-frame and hollow-fiber, each of which has strengths and weaknesses.

Plate-and-frame membranes are usually thin, circular membrane surfaces with a flat and film composite sheet. A thin skin is supported on a thicker layer that has larger pores.

Hollow-fiber membranes consist of an assembly of self-supporting fibers, often up to 10,000 fibers, with dense skin separation layers. One benefit of the hollow-fiber membrane is the very large surface area within an enclosed volume, which increases the efficiency of the separation process.

“The typical MBR is an immersed plate-and-frame membrane or immersed hollow-fiber membrane into the treatment tank, but this isn’t a requirement,” says Cartwright. In addition, he says, many manufacturers are manufacturing hybrid configurations, combining plate-and-frame and hollow-fiber membranes.

There are two other configurations of MBR membranes, in addition to plate-and-frame and hollow-fiber. One is spiral-wound (which virtually all reverse osmosis membranes are), and the other is tubular. “They are not nearly as widely used for MBR, but are certainly possible,” says Cartwright.

Spiral-wound membranes involve a pleated membrane that is folded around a perforated, permeated core, similar to a spiral that is placed within a pressure vessel.

Tubular membranes consist of a pressure tube and hydraulic disks, held in place by a central tension rod and membrane cushions that lie between two disks.

“With so many different configurations available, the challenge for the designer of a municipal treatment system is to decide the appropriate configuration, and then determine which manufacturer offers the best system design,” says Cartwright. “This always requires pilot testing.”

In addition, according to Cartwright, it is possible to design an MBR system without calling it an MBR. “You can take the secondary-treated effluent from the municipal treatment plant, run that through a tubular ultrafiltration membrane, direct the concentrate back to the treatment tank, and then move it on down the line to reverse osmosis and disinfection,” he says. “Is this true MBR? That’s kind of a gray area in terms of what you call it, but you are still using membranes to accomplish the pretreatment.”

One company that offers MBR technology is Ovivo Water. “Our group is focused on wastewater treatment,” says Mike Snodgrass, membrane technology leader for Ovivo’s MBR Group. “Municipal wastewater treatment plants are trying to achieve certain sustainability goals, such as conserving water through water reuse, minimizing energy consumption, resource and nutrient recovery, etcetera,” he says. “These goals drive a lot of their interest in membrane technology.”

The goal of membrane manufacturers these days, according to Snodgrass, is to build better membranes to help municipalities achieve these goals. Two years ago, Ovivo began working with MICRODYN-NADIR in Germany and now exclusively uses their membrane technology in its MBRs. MICRODYN-NADIR offers flat membranes, spiral-wound, hollow-fiber, and tubular membranes. “We selected them because they have excellent operating efficiency, and operating economics in terms of energy usage, membrane life, and effluent quality,” he says. The membranes can be used for effluent treatment after biological treatment, pre-treatment for reverse osmosis (such as sea water desalination), stormwater treatment, drinking water filtration, and other applications.

“In terms of the future, energy continues to be a big focus of MBR systems, such as relying on air scouring processes—the use of aerosols up through the membranes to help keep them clean during operations—in order to drive energy consumption down,” says Snodgrass. “We recently implemented different types of air diffusers, which are unique to the MBR industry, using a technology called AEROSTRIP, out of Austria, which improves efficiency by reducing overall energy demand.” AEROSTRIP diffusers provide efficient aeration processes, which can reduce wastewater treatment plant operating costs.

One satisfied customer of Ovivo’s MBR technology is the Running Springs Water District in Running Springs, CA. In 1999, the US Forest Service advised the district of the need to upgrade its existing Conventional Activated Sludge (CAS) wastewater treatment plant. “Where we discharged our effluent was on Forest Service land, and the Forest Service oversees our special use permit for water discharge,” says Trevor Miller, wastewater treatment division superintendent. “They wanted better quality water. We realized that, in order to get the nutrient removal we needed, the only way we could do it was with MBR.”

So, in 2003, the District switched from a CAS system to Ovivo’s MBR technology. The plant was converted from a BOD-only treatment process, to the first enhanced biological phosphorus removal (EBPR) MBR in the US. EBPR is a sewage treatment configuration applied to activated sludge systems as a way to remove phosphate. EBPR implementations include the presence of an anaerobic tank prior to the aeration tank.

The Ovivo MBR system included a patented design integrating simultaneous nitrification and denitrification (SNdN) into the MBR zones. Waste biosolids were subsequently thickened, digested, and dewatered before being recycled in Mecca, CA.

After the upgrade, the district upgraded the plant even more by installing turbo fans and more efficient membrane units, reducing energy bills substantially.

Recently, the district replaced its MBR system with a newer one from Ovivo. “The life of original MBRs was 10 years, and we were up to 12 in 2015,” says Miller. “The sheets were starting to fail. One option was to replace all of the plates in the existing 15 SMUs, each of which had 300 plates, meaning 4500 plates at $70 a plate, plus the energy they used.” Instead, the district made a decision to replace them completely, since the technology has improved by leaps and bounds in the last 12 years, including improved energy efficiency.

In specific, the district opted for five new Ovivo OV960 Submerged Membrane Units (SMUs). The expected life of these OV960s is 10 years. OV960 SMUs are actually the result of stacking two of Ovivo’s new style OV480 SMUs, which will produce higher permeate flows with a reduction energy consumption.

The OV480 is a flat-sheet technology comprised of four cassettes. Each cassette contains 25 sheets, for a total membrane area of 1,076 square feet. The sheets are resistant to damage and clogging. The cassettes rest on a stainless steel box that is outfitted with AEROSTRIP diffusers.

“The two stacked OV480s to make OV960 is the first installation of its kind, so there were some trials and tests, but none of these involved the membranes themselves,” says Miller. “They have worked fine.” The units have been in place since May 2016, and they are meeting expectations. “They are using half the energy of the old ones,” he says. They are expected to pay for themselves in three years, with savings of about $500,000 over the 10 years.

The Future of Membranes

According to Cartwright, it is unlikely that the “basic four” types of membranes (microfiltration, ultrafiltration, nanofiltration, and reverse osmosis) are going to be replaced any time soon. “Certainly, though, there may be some incremental improvements in each of these four technologies,” he says.

Still, he adds, there are a number of current academic developments in membrane technology, such as graphene, that claim to offer potential. “These are still in the laboratory, though,” he adds.

What are the potentials of graphene membranes? Graphene oxide is a carbon-based material made from naturally occurring graphite (the same material found in pencils). It is a two-dimensional mesh of carbon atoms arranged in the form of a honeycomb lattice. Graphene is so thin that it requires three million layers of it to make a 1-mm-thick sheet, which would allow water to flow extremely fast between the stacked sheets of graphene with very little friction. Graphene is considered to be the lightest, strongest, thinnest, and best heat- and electricity-conducting material ever discovered.

In terms of its potential use, for water treatment in specific, graphene’s “hydrophobia” is of particular interest. That is, graphene naturally repels water. However, when micro-pores are made in the graphene sheets, rapid water permeation is allowed, leading researchers to believe that graphene can be used for water filtration and desalination, once the technology for making these micro-pores becomes available—since micro-pores would allow water molecules to pass, but block the passage of contaminants and other substances.

Perhaps the graphene or graphene oxide membranes will be able to more effectively remove wastewater contaminants, including pharmaceuticals, pathogens, and endocrine disruptors, than existing commercially available membranes.