“Water, water, everywhere, Nor any drop to drink.”

— Samuel Taylor Coleridge

The first requirement for any community is a secure and clean supply of drinking water. This explains why early civilizations were founded along the banks of major rivers such as the Nile, Indus, Yangtze, Tigris, and Euphrates.

While these major rivers provided the necessary quantity of water, the quality was often endangered by contamination from the civilization itself, which made necessary a system to carry away waste and eventually, the filtration of the water supply.

Filtration is defined as “a mechanical or physical operation, which is used for the separation of solids from liquids by interposing a medium through which only the fluid can pass. Oversize solids in the fluid are retained, but the separation is not complete; solids will be contaminated with some fluid and filtrate will contain fine particles (depending on the pore size and filter thickness.” (Source: “Fibers and Fabric for Filtration,” Silajit Naskar). In the context of providing safe drinking water, the solids to be removed are turbidity-causing suspended sediment and microbes (especially pathogens).

The permeability (rate at which water can pass through, typically measured in cm/sec) of the filter medium is proportional to its pore size with total travel time being a function of its thickness. The actual movement through the filter medium is either by gravity or applied pressure/vacuum. This applies a head on the liquid which forces it through the filter media.

Water filtration systems remove the impurities that make water unfit for human consumption. They do so by means of physical barriers, chemical processes, or biological action. Though the ancient Greeks and Egyptians understood basic water treatment methods, such as bag filters to sieve water and the addition of alum to allow the removal of impurities by coagulation, the first water filter systems for domestic use were built during the Enlightenment era, with the first public filtration and treatment system built in Scotland in the 19th century. Made from alternating layers of wool charcoal, these early filtration systems were eventually replaced by the late 1800s by large-scale sand filters that serviced entire cities.

But now that basic water filtration is a mature technology that has been adopted worldwide, a new challenge has presented itself to a world with almost 8 billion people (half of whom now live in cities): the need to desalinate large quantities of seawater in an efficient and cost-effective manner. Not only are natural sources of freshwater stressed from excessive demand, but extreme weather and drought threaten the sources of freshwater for entire regions of the globe. To meet these new demands, new filtration technology utilizing graphene and other exotic materials are being developed and deployed.

These new filters operate at the atomic level, with the carbon rings forming the sheets of graphene (which itself can theoretically be one atom thick) presenting holes large enough to let water molecules pass but retain impurities such as sodium chloride molecules. Such membranes, reinforced by walls of epoxy resin, have been shown to effectively remove salt from saltwater. As a result, the world could have access to vast amounts of freshwater directly from the world oceans—enough water to quench the thirst of billions of people and provide enough irrigation water to turn the planet green. Our current scarcity of drinking water could become a thing of the past.

NATURAL WATER FILTRATION

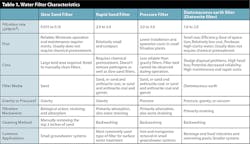

The world is not short of water. The world is short of potable water. Water filtration systems address this shortage. The most basic materials used as water filtration media are some of the most common: sand and diatomaceous earth. The table on the following page summarizes the characteristics of each type of filter.

Simple operation, high reliability, ease of construction, and low operating costs are the hallmarks of slow sand filters. These characteristics make them the most prevalent system for small and mid-sized rural communities and were the earliest method developed for large-scale water filtration. Because of their simplicity of operation, only the most basic skills are required of its operators. They effectively and efficiently remove both sediment and turbidity via physical screening and pathogens with biological and chemical processes.

This is accomplished by a single pass through operation that takes in contaminated water at the top and yields potable water for extraction at the bottom. Unless the intake water is suffering from an excessive amount of algae contamination or extremely high degrees of turbidity, a sand filter can by itself perform the necessary purification operations without the need for pre-treatment. The World Health Organization has designated slow sand filtration as the least expensive, simplest, and most cost-effective means of providing potable water.

The simplicity of the slow sand filter comes from its design. Contaminated water enters at the top through the upper surface of the sand layer. Both the physical screening and biological treatment occurs at this location. The first step is removal of sediments by the sand physically acting as a sieve, its pores allowing water to pass through, while being too small to allow further migration of sediment and turbidity particles. But of greater importance is the natural anti-pathogen treatment it provides.

This is based on the ability of bacteria to attack and consume these disease germs. The top layer of the sand quickly becomes biologically active with the development of a scummy layer called schmutzdecke, German for “dirty skin.” The microbial community attaches itself to sand particles exposed at the top surface of the sand layer within a few days of operation. The established microbes are mostly predatory bacteria that attack and consume water-borne disease pathogens. This biological surface film must be manually or mechanically scraped off at regular intervals to prevent clogging. And in general, a slow sand filter must have a relatively large surface area to manage large quantities of water at slow flow rates.

A rapid sand filter differs from a slow sand filter in several aspects, not just filtration speed and flow rate. Essentially, rapid sand filtration is a physical process as opposed to the biological process utilized by slow sand filters. Rapid sand filters either use gravity drainage to move water through the system or they apply high pressure to the water flows. Since a rapid sand filter is primarily physical in nature, some biological pre-treatment and post-treatment is typically required. These include coagulation combined with flocculation and the addition of chlorine to ensure disinfection. Also, unlike the slow sand filter, the construction and operation of a rapid sand filter is both complicated and relatively expensive. However, rapid sand filters are the appropriate choice for developed nations and communities with sufficient resources to build them and skilled engineering staff to operate them.

The primary rapid sand filter unit is typically a cylindrical chamber or a square tank made from reinforced concrete. The chamber is filled with alternating layers of sand and gravel to a height of about 6 feet. The bottom is lined with a series of perforated pipes that collect and extract the purified water. Rapid gravity filters have open tops, are simpler to construct and operate, and don’t need large powerful pumps, but they have lower flow rates. Rapid pressure filters have completely enclosed tops, are more complicated, utilize large pump systems, and can handle large flow rates—making them more suitable for servicing larger communities. In either case, filtration results from the clogging of sand pores with larger particles of sediment while smaller particles physically cling to sand grains due to Van der Walls forces. The addition of coagulants or flocculants to the water in feed promotes increased adhesion and clumping of particles, increasing removal efficiency.

Like the slow sand filter, clogging of a rapid sand filter can occur over time. However, instead of mechanical removal, the rapid sand filter is cleaned by reversing the water flow under high pressure to cause back-washing of the accumulated material out of the top of the filter unit. The reverse flooding of the chamber causes the sand particles to be suspended, increasing the void volume between the sand grains. This allows enough room for the lifting and removal of sediment particles out of the sand media. To assist this process, high-pressure air is often injected as well. The large quantities of sludge produced by the backwashing process require their own management and disposal operation.

The diatomaceous earth filter differs from other natural filters primarily in the material used as the filter media. Diatomaceous earth isn’t soil at all. Instead, it consists of a powdered media made up of almost pure silica. This silica is manufactured from diatoms, the hard-shell skeletons of freshwater single-celled algae. Primarily used for small-scale applications where water purification standards are very high, such as public and private swimming pools, these tend to be more expensive than standard sand filters. Their effectiveness is a result of the microscopic pores found in the hard-shell bodies of the algae. These provide very effective mechanisms for trapping impurities.

There are three primary types of diatomaceous earth filters: horizontal plate, vacuum, and pressure. In vacuum filters, negative pressure is applied to force the water through the filter medium. This allows for a configuration with a large contact surface area in proportion to the filter chamber’s overall volume. This greater surface area allows for higher flow rates. Pressure filters, which use applied pressure to deliver water to the filter chamber, are more limited in their size and are used for smaller-scale applications. Horizontal plate filters are a kind of pressure filter with the filter medium arranged in parallel with horizontal filter plates. After backwashing with compressed air through the filter plates, the residue is trapped on the horizontal plates, allowing for easy removal.

MAN-MADE FABRICS, MEMBRANE, GRAPHENE, AND OTHER WONDER MATERIALS

Natural earth isn’t the only type of filtration material. Man-made fabrics have been used to filter and sieve water for millennia. Traditional cloth filters are inexpensive, low-tech, and relatively easy to use. While not 100% effective, this simple method can greatly reduce floating parasites, pathogen counts, and turbidity in drinking water taken directly from river and groundwater well sources. Studies have shown that even a simple wrapped cloth can greatly reduce the incidence of cholera in third world villages that lack more sophisticated water purification systems.

Similar in principle but far more advanced in application is the process of reverse osmosis filtration. “Reverse Osmosis (RO) is a water treatment process that removes contaminants from water by using pressure to force water molecules through a semipermeable membrane. During this process, the contaminants are filtered out and flushed away, leaving clean, delicious drinking water” (ESP Water Products).

Reverse osmosis achieves this purification by means of a semi-permeable membrane that traps and removes particles as small as individual ions and molecules. To overcome inherent osmotic pressure, high pressure is applied to the water that forces the liquid across and through the membrane, leaving contaminant particles and molecules behind. This applied pressure reverses the natural direction of flow, thus the description of the process as reverse osmosis. While this may seem similar to pressure filtration, there are significant differences between the two processes, not the least of which is the filter medium. Reverse osmosis involves both straining (exclusion of particles based on their size compared to the open pores) and diffusion. As such, reverse osmosis has found its most widespread use in the area of seawater desalination since it can remove individual salt molecules as well as sediment and microbes.

Most drinking water purification systems, whether individual home systems or giant community systems such as the facility used by Orange County, CA, utilize reverse osmosis. Some of these systems involve multiple steps to accomplish the conversion of seawater into potable water: an initial sediment filter (or two filters in sequence with progressively smaller pore sizes) to trap large particles, activated carbon to trap organic chemicals (such as chlorine), and finally the reverse osmosis membrane itself. Advanced systems may employ post-membrane carbon filtration and an ultraviolet sterilization lamp to kill any remaining microbes.

Membrane pore sizes can vary depending on the type of contaminants to be removed and the type of filter material. The pore size range is from 0.1 to 5,000 nm (4 x 10−9 to 2 x 10−4 inches). This pore size range is broken down into five size categories: particle, microfiltration, ultrafiltration, nanofiltration, and hyperfiltration. Particle filtration removes particles of 3.9 x 10−5 inches or larger. Microfiltration removes particles of 1.9685 x 10−6 inches or larger. Ultrafiltration removes particles of roughly 1.1811 x 10−7 inches or larger. Nanofiltration removes particles of 3.937 x 10−8 inches or larger. Reverse osmosis is performed by membranes with pore sizes in the hyperfiltration range, removing particles larger than 3.937 x 10−9 inches.

The membranes used by reverse osmosis units are typically semi-permeable, thin-filmed composites. The membrane itself is a thin (less than 7.874 x 10−6 inches thick) polyamide layer placed on top of a porous polyether-sulfone or polysulfone layer of about 0.0019685 inch thick. These are, in turn, fixed to a non-woven fabric substrate that provides physical strength and support. Most of the work of desalination is done by the polyamide layer which has an affinity for water molecules while it rejects dissolved salt ions.

Going from ancient times to the Space Age gives us man-made filtration materials such as graphene. Graphene is a version of carbon that forms a two-dimensional lattice of carbon atoms arranged in a repeating hexagon pattern. Often touted as the strongest material on earth, it is also being researched as the ultimate water filtration medium. The openings of these hexagons create pores that are sized to remove not just microbes and soil particles, but also individual molecules. Its applications are not limited to water cleanup and desalination. It is also applicable to a wide range of industrial processes such as protein separation, wastewater treatment, and drug and pharmaceutical production.

Graphene is also the world’s strongest material, at least ten times stronger than steel, but that’s the least of its attributes. Its molecular structure allows it to act as a sieve small enough to cheaply and effectively remove salts from seawater. At first, graphene-oxide membranes were shown to be able to remove larger salts from seawater. Recent advances have shown its ability to remove the smaller salts that make up the bulk of seawater contaminants. Researchers have, in effect, shown that they can create membranes of uniform pore size right down to the atomic scale.

This allows for greatly reduced costs and energy requirements for desalination. More than half of the battle in desalination is applying the pore pressure necessary to push water through, while salt is trapped and accumulates near pore openings. When this advancement is far enough along to be scalable, a low-cost desalination method may become available.

Another approach is to embed graphene in bacteria-produced cellulose. The resultant product is a bi-layered biofoam. It has the ability to absorb light and, as it heats up, freshwater is evaporated. The biofoam consists of two layers of nanocellulose, both of which are created by bacterial action. The top layer is embedded with graphene oxide which is heated by the sun, while the bottom layer has a sponge-like consistency that pulls water up into the biofoam. When the water comes into contact with the upper graphene embedded biofoam, it evaporates and can easily be recovered as freshwater from the accumulated condensate. Both graphene oxide and the biofoam are cheap to produce. This allows mass production of tons of material at a time, making the approach highly scalable.

Another approach emphasizes ease of manufacture. It involves a spray-on, graphene-based coating applied to desalination membranes. The resultant product is durable and sturdy, capable of surviving even harsh operating environments. The membrane filter is able to function at high flow rates, is self-repairing, and has a long operational lifetime as it filters out salts and pollutants to generate clean drinking water without being subject to bio-fouling.

The hybrid membrane is created by simple spray-on applications that coat a mixture of graphene oxide and few-layered graphene onto the surface of a polysulfone membrane. The polysulfone has had its molecular structure modified by polyvinyl alcohol and serves as the structural substrate of the membrane. This structural support strengthens the membrane, allowing it to withstand high pressure and exposure to chlorine. It can easily remove up to 85% of salts (making the water suitable for agricultural applications) and up to 95% of chemicals such as industrial dyes.

MAJOR INDUSTRY SUPPLIERS

Dow Water & Process Solutions produces a family of reverse osmosis membrane filters capable of purifying different degrees of contaminated, brackish, and saline water. The company’s Dow Filmtec Brackish Water RO Elements come in various sizes for different applications. The 8-inch-diameter model treats difficult industrial water, enabling lower energy usage and reduced costs. The models sized 4 inches and smaller are designed to handle light industrial brackish water and commercial brackish water respectively. Similarly, the Dow Filmtec Seawater RO Elements comes in differing sizes with the 8-inch-diameter model featuring high active membrane areas with low net driving pressure. Greater flow rates are achieved with the 4-inch diameter and smaller models.

Evoqua Water Technologies provides a wide range of water and wastewater treatment products and materials. These include cross-flow, micro-sand filtration systems, and pressure filter systems, as well as membrane filters for reverse osmosis and ultrafiltration.

Pentair Water Filtration Division produces 3-stage (GRO-350B), 4-stage (GRO-475B & GRO-475M), and 5-stage (GRO-575B & GRO-575M) reverse osmosis systems. The filtration units can remove lead, volatile organic compounds, chlorine, biological contaminants that cause bad taste and odor, cysts such as cryptosporidium, and discoloring turbidity.

Scinor Water America emphasizes the production of the membranes themselves. These are hollow-fiber membranes made from Polyvinylidene Fluoride (PVDF) using the thermally induced phase separation (TIPS) method of manufacture. Using their own proprietary designs and configurations, they manufacture membrane modules which serve as direct retrofits. They require no additional hardware and are essentially plug-and-play units easily inserted into existing filter systems.