As the world’s population grows, the number of people facing water scarcity issues is expected to rise, with some estimates pitting the number of people experiencing water shortages to be at 60 percent by 2025. With 97 percent of the world’s water in oceans, seawater desalination represents a major opportunity for alleviating water stress across the globe.

But the process can be expensive and time consuming due to the complexity of the treatment process. At most plants, electrical energy accounts for about 35 to 40 percent of total operating costs, which is why sustainable, energy-efficient desalination is at the forefront of research into developing clean water technologies.

Today, more than 20,000 desalination plants are operating in 150 countries, according to data from the American Society of Mechanical Engineers. The two main types of desalination processes are membrane (reverse osmosis, or RO) and thermal, which includes multi-effect distillation (MED) and multi-stage flash distillation (MSF) technology.

“Any proper water treatment process, especially desalination, consumes energy,” Peng Wang, professor of environmental science and engineering at Saudi Arabia’s King Abdullah University of Science and Technology (KAUST), said, underscoring the importance of developing a clean-energy driven desalination protocol across the globe. “For example, in Saudi Arabia, around 10 percent of the [country’s] electricity is used for seawater desalination. In Abu Dhabi, the desalination sector contributes more than 22 percent of the Emirate’s total CO2 emissions. Given the fast growth of global desalination capacity, development of clean-energy driven, energy-efficient freshwater generation, particularly seawater desalination, is more urgent than ever nowadays.”

In an effort to generate both energy and water using a renewable energy process, Professor Wang and a team from KAUST have developed a system that captures heat shed by solar panels to be used to generate clean drinking water.

“Among all renewable energy, solar energy has the highest natural abundance and lowest geographical limitation,” Wang said. “Solar power generation by photovoltaics (PV) occupies the central piece in the global fight against climate change. PV panels, however, suffer from an over-heating problem during daytime, especially in arid and semi-arid regions where solar irradiation is high. In summer, PV panels in these areas can be 104° F hotter than the ambient air. Therefore, there is a huge amount of heat produced and wasted on PV panels daily.”

Wang’s research team has developed a strategy of photovoltaic-membrane distillation (PV-MD), which turns the extra heat generated from PV panels into a power source to drive a multistage membrane distillation (MD) process to produce fresh water from seawater. In the PV-MD system, the MD component is attached directly onto the back of commercial PV panels and the heat produced by the PV panels flows into the MD component naturally. While the heat flows through the multistage MD, the latent heat from vapor condensation is collected and reused to drive multiple cycles of water evaporation, leading to a high freshwater production rate.

“The beauty of PV-MD is that the water desalination [process] on the backside of the PV panel does not affect regular electricity generation by PV, achieving simultaneous and efficient generation of electricity and fresh water on the same panel,” he said. “The two processes — electricity generation and water desalination — are solely driven by solar energy.”

Energy efficiency and Blue Prussian analog particles

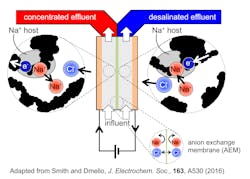

While solar energy can bring desalination processes forward in their quest to obtain sustainability, looking at battery power could also help alleviate some of the energy-efficiency issues in the process, as is shown by research from the University of Illinois at Urbana-Champaign. For the past several years, university researcher Kyle Smith has proven his growing expertise in the field of water desalination through various projects. Smith’s latest work involves deionization devices that can reversibly store and release cations using a class of materials commonly used for rechargeable batteries: intercalation materials. This work in particular addresses the challenge of cycling intercalation materials with fast rates of electron, ion, and fluid transport, features that are difficult to achieve simultaneously in a single system.

“The process that we are developing uses battery-type materials to absorb and release ions from water,” Smith said.

His team fabricated optimized electrodes containing insulative Prussian Blue analog particles, and used them in an experimental cation intercalation desalination (CID) cell with symmetric electrodes. Results of the experiment showed a nearly 10-fold increase in the rate of salt removal at similar energy consumption levels to past CID demonstrations. The use of such materials has the potential to reduce the environmental burden of desalination by leveraging the very high ion concentrations that are achievable inside of these solid materials (approximately 4 moles of sodium per liter for Prussian blue analogs).

“In principle, this high degree of ion storage can be used to get high water recovery in desalination, thus producing minimal brine that requires disposal or further treatment,” he said. “Such materials also have an ability to absorb particular ions in a selective way, which opens up opportunities for more efficient water treatment processes where only specific contaminants need to be removed.”

While the technology has until now only been tested on a small scale, Smith says the potential for scaling up to be used in large desalination plants is possible.

Moving toward the future of desalination

Advances continue to be made in desalination technology, especially incorporating “smart” applications. Smarter systems designed to detect, anticipate, and manage desalination issues before they become significant problems, as well as improvements in process control, monitoring, and response, have the potential to enhance day-to-day operations.

To that end, the U.S. Department of Energy (DOE) recently announced the launch of the $9 million American-Made Challenges: Solar Desalination Prize, a competition to accelerate the development of systems that use solar-thermal energy to produce clean water from very-high-salinity water.

“Using solar-thermal desalination to clean nontraditional water sources offers a new pathway to generating water for municipal, agricultural, and industrial use,” the agency said when announcing the competition.

In April, the MIT Water Club hosted its annual Water Innovation Prize Pitch Night, the culminating event of a year-long international competition for student innovators seeking to launch water sector companies.

An MIT team, Harmony Water, took home a third-place prize of $7,500 to support their continued research and development of a low-cost water desalination system that can produce more water and less brine using 30 percent less energy than present methods.

“In the standard treatment process, the reverse osmosis desalination stage separates feed into product water and brine, however, managing the brine can cost up to 10 times more than disseminating the water,” Sahil Shah, a representative from Harmony Water, said during the pitch event.

“Instead, we can decrease the brine volume by two to four times, thereby cutting the cost of water production for the same plant, without affecting production rate, energy consumption or membrane usage.”

The company’s patented batch RO system applies just enough pressure to exceed the osmotic pressure and produce water, rather than providing constant pressure at the expense of energy in traditional RO systems.

“Given the high cost of managing brine, the most cost-effective use of the same energy is to recover more water and decrease brine… saving 20 percent on the plant’s capital costs for the small scale plants that we’re initially targeting with this system,” Shah said.

Currently, Harmony Water is in discussion with PUB, Singapore’s National Water Agency, and others, and is seeking a commercial partner, with hopes to pilot the system in the next two years. WW

About the Author

Alanna Maya

Chief Editor

Alanna Maya is a San Diego State University graduate with more than 15 years of experience writing and editing for national publications. She was Chief Editor for WaterWorld magazine, overseeing editorial, web and video content for the flagship publication of Endeavor's Water Group. In addition, she was responsible for Stormwater magazine and the StormCon conference.