Utilizing Microfiber Media to Achieve 0.1 mg/L Total Phosphorus Limit

With the current national emphasis on restoring the water quality of America’s urban waterways, the City of Brockton, Mass., Advanced Water Reclamation Facility (AWRF) wanted to stay ahead of the regulatory cycle — in particular, phosphorus discharge limits set forth by the National Pollution Discharge Elimination System (NPDES) program of the United States Environmental Protection Agency. For this region of the country, EPA has proposed total phosphorus (TP) discharge limits of 0.1 mg/L.

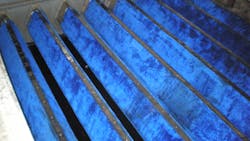

The Brockton plant’s existing treatment scheme included physical settling (primary treatment), activated sludge treatment (secondary treatment) and final filtration (tertiary treatment) using two AquaDiamond® cloth media filters (CMFs) from Aqua-Aerobic Systems Inc. Even though the filters performed to a level well below the current phosphorus discharge limit of 0.2 mg/L, Plant Superintendent Dave Norton began looking for ways to not only improve the plant’s removal efficiency to meet the anticipated 0.1 mg/L limit, but to achieve it with minimal equipment modification and without raising operating costs with chemical addition.

Following preliminary evaluations of incoming phosphorus levels, the Brockton AWRF staff, working with Aqua-Aerobic Systems, conducted full-scale tests using OptiFiber PES-14® microfiber cloth media installed on one of the AquaDiamond filtration units and compared its performance to the unit using the existing OptiFiber PES-13® pile cloth media. Each unit provides 238 m2 (2,560 ft2) of filtration area and is rated for a nominal average daily flow of 1,900 m3/hour (12 MGD) and a maximum daily flow of 3,800 m3/hour (24 MGD).

- During normal operating conditions of approximately 6 m3/m2/hour (2.4 gal/min/ft2)

- At the average design hydraulic loading rate (HLR) of 8 m3/m2/hour (3.25 gal/min/ft2)

- At the peak HLR conditions approaching 16 m3/m2/hour (6.5 gal/min/ft2).

The two filter units operated under identical flow and loading conditions during the full-scale study. The results show that the OptiFiber PES-14 microfiber media consistently reduced phosphorus levels to below the 0.1 mg/L target. Additionally, the microfiber media outperformed the existing pile cloth media with respect to final total suspended solids, turbidity, particle size distribution and iron concentrations and fared extremely well during average design and peak HLR testing.

“We all anticipated a potential 20-25 percent reduction in hydraulic pressure loss across the filters,” said Norton. “I don’t believe we saw that. Also, I do not believe we have seen the increase in backwashing volume which was predicted.”

The Brockton AWRF has demonstrated that it can meet the anticipated future discharge standards for total phosphorus. Furthermore, because of this demonstrated success, the plant, working in conjunction with Aqua-Aerobic and its consulting engineering firm, has installed and commissioned a third and fourth AquaDiamond CMF (with the OptiFiber PES-14® microfiber media). The AquaDiamond control unit from the full-scale test is also being retrofitted with the microfiber media.

“Retrofitting the filter units from the original pile cloth media to the microfiber media had minimal impact on the current equipment and was relatively simple, Norton said.” WW

Learn more about Aqua-Aerobic Systems at www.aqua-aerobic.com.