Achieving Safe Fluoridation Through On-Line Monitoring

In many parts of the world, fluoride is added to public water supplies to help improve dental health. Fluoride is found in all natural water to some degree. Surface waters generally have low concentrations of fluoride, typically around 0.5 mg/L. Groundwater may contain much higher levels of fluoride if it has been excessively exposed to inorganic minerals containing fluoride.

Given the potentially hazardous nature of the chemicals used in fluoridation and the potential consequences of over-fluoridation, the addition of fluoride to drinking water must be accurately controlled and carefully monitored to ensure that locally set operational criteria is adhered to. Based on these concerns, the World Health Organization (WHO) has set an upper limit of 1.5 mg/L for fluoride in drinking water.

ABB’s Aztec 600 Fluoride offers reliable and accurate on-line analysis of fluoride concentrations throughout the treatment process.

Accurate dosing of the chemicals used to fluoridate the water can be further complicated by underlying levels of natural fluoride in certain areas. In these areas, the dosing of chemicals to the water supply must be adjusted to take account of the existing natural background levels.

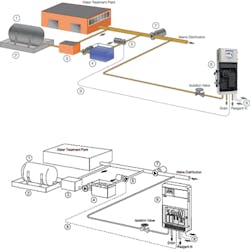

Incorporating a range of features, including high- and low-level alarms, ABB’s Aztec 600 Fluoride offers reliable and accurate on-line analysis of fluoride concentrations, allowing immediate process decisions to be made to help preserve the safety of the treatment process.

A sample is first drawn from the sample chamber by the sample pump. In some drinking waters, there may be a residual of iron or aluminum from the chemical coagulants that have been added during the water treatment process. These metal ions can form a complex with the fluoride, which can complicate the analysis.

To ensure an accurate measurement, the sample is pretreated with a chemical buffer reagent before it is analyzed. This adjusts the ionic strength and buffers the sample pH. The reagent also contains a chelating agent that breaks up metal-fluoride complexes. This reagent is pumped into the sample line and mixed with the sample. The conditioned sample is next passed through a temperature block to raise the temperature and provide further mixing before being presented to the fluoride electrode. The electrode output is converted by the microprocessor to indicate the direct fluoride concentration in ppm, mg/L, ppb, g/L or in graphical format. Finally, the sample flows to waste.

It is important that the temperature of both the sample and the electrode are controlled to prevent any variations that could affect the electrode potential, resulting in significant measurement errors. The Aztec 600 ISE fluoride electrode is therefore housed in a fully enclosed, temperature-controlled cell. This cell also helps to adjust and stabilize the sample temperature prior to the electrode, ensuring that a constant temperature is maintained during both calibration and measurement. To help operators verify analyzer performance, the Aztec 600 Fluoride features automatic two-point calibration with separate high and low standard solutions. Calibration frequency can be programmed to occur either weekly or up to four times per day. WW

ABB’s global water and wastewater application expertise and knowledge make it an ideal partner throughout the entire water cycle. To learn more, visit www.abb.com.

Circle No. 250 on Reader Service Card