Wellness for the Nose – Breakdown of Chloramines in Public Baths

By Thomas Lödel

• The usage of modern UV technology reduces chloramines and inactivates pathogens like viruses, bacteria and microbes in public baths.

Simply to relax. To soak the body and soul in warm water. To lose the cares of the day in a whirlpool. Happy sounds of children on the water slide, while the really small splash about gleefully in comfortably warm baby pools.

Public baths today are often more than pure sports facilities. They're places for relaxation and well-being for big and small alike. The typical swimming pool chlorine smell, which used to sting our nose when we entered the swimming pool, along with red and irritated eyes of children, are no longer in tune with the wellness concept of modern swimming centres.

Chloramines as Triggers

Chlorine is routinely used for disinfection in public baths. This classic disinfection mechanism cannot be completely substituted as, with other solutions, the high disinfection power and necessary germ-killing speed cannot be achieved. In the ongoing operation of baths using chlorine, chloramines such as NH2Cl (monochloramine) are produced as disinfection by-products (DBPs) through free chlorine and organic substances such as skin shed into the water. These chloramines, also known as "combined chlorine", are responsible for the typical swimming bath smells and irritation of the eyes and mucous membranes. Chloramine concentration is dependent on several factors: water temperature, pool temperature, number of bathers and their level of activity and the process of water treatment. Theoretically, the greater the number of bathers, the greater their level of activity, the higher the water temperature and the smaller the pool size – then the larger the amount of chloramines. The upper limit of combined chlorine is given in the German regulation DIN 19643 at 0.2 mg per litre.

Photochemical Reaction with UV

One good possibility for reducing the concentration of DBPs in the water circuit is the Chlorominator (see Figure 1) from water treatment specialist Grünbeck in Höchstädt an der Donau, Germany. Combined chlorine is broken down photochemically in this system. With the help of high energy UV emitters, molecular bonds of the chloramines are broken, resulting in harmless substances such as chloride and nitrogen. In practice, the system consists essentially of a pressure tube with two overlapping UV irradiation zones. In the influent zone, according to system capacity, there are up to six 400 Watt UV medium pressure lamps from specialist light source manufacturer Heraeus Noblelight (see Figure 2).

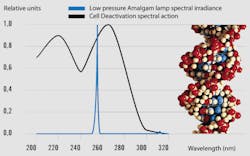

Due to the polychromatic lamp spectrum in the UV-C spectral range from 200 to 280nm, which is effective for the application, as well as a specific electrical emitter power of over 45 W/cm, the UV lamps break the chloramines molecular bonds and so destroy the combined chlorine in the bath water (see Figure 3).

Figure 3. Typical polychromatic lamp spectrum of UV medium pressure lamps.

As this process relies exclusively on application of UV technology and requires no additional substances, the chloramines destruction is environmentally friendly. Virtually all of the heat generated is fed to the bath water and this makes the process energy-efficient and economical. The high radiation flux of the UV medium pressure lamps allows construction of compact water treatment systems. Specifically, the 400 Watt UV medium pressure lamps are only 140mm in length with a diameter of around 16mm.

UV Reduces Chlorine Need

As well as destroying chloramines, use of UV lamps also allows for a reduction in the amount of chlorine required. Treatment of water with UV radiation is a very effective physical process for disinfection of water and destruction of pollutants. High energy UVC radiation in the range 200 to 280nm destroys the bonds of the DNA helix, effectively neutralizing in seconds the cells of pathogens such as viruses, bacteria and microbes that can be present in water. Employed properly, these same pathogens also are unable to develop any resistance against UV light. Consequently, the germ count in the swimming bath water can be reliably reduced, meaning less chlorine is needed for residual disinfection.

To further increase this effect, the Chlorominator also features up to 12 Heraeus Noblelight low pressure amalgam lamps (see image at top of p. 1) and the UV medium pressure lamps. These are located in the outlet of the irradiation chamber. With their quasi- monochromatic spectrum of 254nm and high efficiency of around 35%, they're well suited to disinfection of the water in swimming baths (see Figure 4).

Compared with conventional mercury low pressure lamps of the same geometry, amalgam lamps offer significantly greater power. While mercury low pressure lamps typically have a specific electrical power of 0.3-0.5 W/cm of illuminated length, amalgam lamps approach 6 W/cm because of a different pressure/temperature ratio. Mercury low pressure lamps achieve optimal mercury vapour pressure of 0.8 Pa, and hence their maximum UVC output, at around 40ºC. Increasing or reducing temperature by increasing or reducing electrical input power only leads to a reduced UVC output.

The amalgam lamp also reaches its optimum vapour pressure at 0.8 Pa, but this is at a corresponding temperature of 90-130ºC (depending on the model). This higher level temperature is responsible for the higher specific electrical power of the amalgam lamp and thus for its higher UVC output per centimetre of illuminated length. As such, amalgam lamps are much more compact than mercury lamps of the same output. Consequently, system builders can scale down equipment, as they need fewer lamps and casings and hence less space. A smaller number of power supply units is also another potential saving.

A Case in Point

The Chlorominator, with its advanced UV technology, is already in use in a large number of swimming bath installations. Recently, the newly built spa centre at Bad Liebenstein, Germany, received two of the UV generators. Bad Liebenstein is the oldest spa town in the central German state of Thuringia. This new spa was to be opened in Spring 2009. Amongst other things, it offers a swimming pool, speciality showers, a sauna suite with ice tubs and immersion pools, and relaxation baths using the local spa water. Here, the oldest spa and curative bath in Thuringia, (the healing and curative effect of the water from the Casimir spring has been acknowledged since 1601) is now using modern water treatment with UV technology as well. Medium pressure and amalgam low pressure lamps cut the chloramines in the water and help water disinfection, so facility users can safely and peacefully relax, from top to toe, and look forward to their next visit.

Author's Note: Thomas Lödel is marketing manager for Heraeus Noblelight GmbH of Hanau, Germany. With subsidiaries in the USA, UK, France, China, Australia and Puerto Rico, the Heraeus Group member makes infrared and UV emitters for various applications in industrial manufacture, environmental protection, medicine and cosmetics, research, development and analytical laboratories. Contact: +49 6181 35-9379, [email protected] and www.heraeus-noblelight.com

More Water & WasteWater International Issue Articles

More Water & WasteWater International Archived Issue Articles