Titanium pump avoids corrosion problems

By: Morten Gylling

Seawater desalination presents significant challenges for pumps and their components such as struggling localised corrosion due to chloride attack of the stainless steel passive layer. Moreover some stainless steel (e.g. AISI 304 and AISI 316) is susceptible to stress corrosion cracking - the brittle cracking of metal due to the result of combined effects from localised corrosion and tensile stress.

Salt water is a highly aggressive liquid that almost inevitably leads to corrosion in metal and alloys with which it comes into contact. This often means expensive downtime, high maintenance costs and reduced working life for equipment - all serious problems that can be avoided by owners and operators of desalination production facilities.

Titanium possesses highly attractive properties in applications where long-term reliability in aggressive environments is crucial. Titanium has many properties that no other metal can match. Titanium's strength and low density produce a strength-to-weight ratio superior to almost any other metal and is as strong as steel but almost half the weight, and twice as strong as aluminium.

For industry, the crucial advantage is that titanium is almost immune to corrosive attack by saline solutions in addition to being virtually unaffected by most oxidising acids and industrial chlorine solutions. This makes titanium applicable for use in extremely harsh, corrosive environments - such as sea water.

Traditionally, its high cost prohibited industrial use. With advances in modern technology, and because titanium's properties far outstrip those of other metals and thus result in significant cost savings in other areas, its use has now become a viable option in industrial applications.

The Danish company Grundfos recognised the potential advantage of titanium and conducted award-winning research that resulted in the development of titanium pumps. The Institute of Materials in London, England awarded the Titanium Prize 1999 to Grundfos for this research.

Grundfos' manufacturing operations in Bjerringbro now include serial production based on sheet forming of components for titanium pumps. These pumps provide users with problem-free, long-term operation in high-corrosion installations such as desalination plants, wastewater processing and water treatment systems, and in power stations, ships, offshore installations and chemical plants.

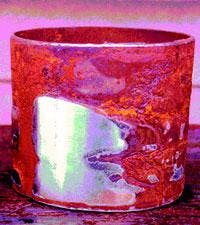

Grundfos supplemented its CR range of pumps with the CR Titanium range, in which all components that come in contact with the pumped liquid are made of titanium. CRT pumps are an integral part of the company's comprehensive series of pump solutions, where each pump type is available with a range of different specifications and accessories to meet particular project specifications.

Titanium features a highly stable oxide film that completely protects the surface of metal against corrosion. CRT pumps, which are fully resistant to solutions of chlorites, chlorates, hypochlorites and chlorine dioxide, are also fully resistant to oxidising metallic chlorides used in water treatment, the electronics industry and metal refining or plating. CRT pumps prevent corrosion in seawater environments; not even a decade of immersion in salt water would have any effect.

Author's note

Morten Gylling is the product business manager of Grundfos A/S, based in Bjerringbro, Denmark. For more information, visit the website www.grundfos.com