Laying the Foundations for Automated Coagulation Control

Extensive trials at utility Severn Trent show the value of using zeta potential as a lead measure of performance for natural organic matter (NOM) removal processes. This article examines the company’s experience highlighting the benefits delivered.

By Alon Vaisman, Adam Hall, Kerry Hall, Emma Sharp and Joanne Claronino.

Continuous monitoring technology can help to safeguard drinking water quality, even in the event of rapid changes in raw water, while simultaneously supporting the move towards greater automation and improvements in cost efficiency. Zeta potential is a measurement increasingly popular for monitoring of charge neutralization performance in water treatment flocculation processes.

UK water company Severn Trent is using measurements of zeta potential to enhance coagulation control. Trials at the company’s Tittesworth Water Treatment Works (WTW), a 40,000 m3/day facility located in Leek (Staffordshire, UK), indicate that online zeta potential measurements provide a reliable and highly effective lead measure of performance, for controlling the clarification process associated with the removal of Natural Organic Matter (NOM) in incoming water.

Focusing on NOM Removal

A critical challenge in water treatment is the timely and efficient removal of NOM. The level of organics now routinely flooded into the aquatic environment during events such as snow melt or heavy rainfall is rising, increasing loading on the clarification circuit and the importance of effective control of residuals to mitigate creation of disinfection byproducts (DBP’s) later in the process.

Sedimentation is the primary process used to remove particulates but these are usually quite fine (< 1000 μm) making settling under gravity a relatively slow process.

At Tittesworth WTW positively charged ferric salts are used to neutralize the negatively charged NOM and promote flocculation i.e. a charge neutralization process. Dissolved air flotation is then deployed to separate the flocs which must therefore be sufficiently stable to withstand this and subsequent physical separation processes. Minimising chemical usage and the risk to water quality associated with a sudden variation in raw water contaminant levels or chemistry are key operational goals.

Traditionally, jar tests have been used by Severn Trent to monitor flocculation and provide data on which to base coagulant dosing levels. The jar test is a manual procedure which involves dosing an extracted water sample and monitoring the resulting flocculation/settling. It can take up to 30 minutes to complete, creating a significant time delay between sampling and the receipt of results, and, since the analysis is subjective, results can exhibit significant variability. The practicalities of measurement mean that analysis cannot be carried out sufficiently frequently to be 100% confident of water quality at all times and, crucially the technique does not robustly indicate to the operator how to change the coagulant dose in response to a poor result.

Investigating zeta potential

Zeta potential is a measure of the magnitude of electrostatic or charge repulsion at the boundary layer surrounding a particle, and therefore provides a reliable indication of whether particles in a suspension are likely to coagulate or to remain discrete.

Suspensions with a zeta potential close to zero are highly prone to aggregation so maintaining a system in this range will encourage the creation of flocs. A highly positive or negative zeta potential on the other hand, is indicative of a stable system in which the particles will remain discrete.

Zeta potential measurements are fast, with modern systems delivering measurement in less than five minutes, and automated, so not susceptible to the operator variance associated with jar tests.

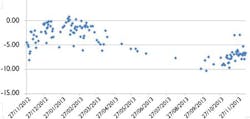

Severn Trent began evaluating zeta potential as a metric for clarification control in 2007 with a series of bench-scale experiments investigating the link between zeta potential and clarified water quality, as quantified by turbidity measurements.

Multiple analyses were carried out on water derived from a number of geographies and the results revealed a universal relationship between zeta potential and clarification performance that held for all water sources. Zeta potential values consistently associated with good performance in the charge neutralization process were in the range -10 mV to + 3mV suggesting that measuring zeta potential would provide a clear guidance for plant control. Zeta potential can be maintained in the required range by manipulating either coagulant dosage level or pH, which affects the charge on the coagulant and consequently its impact.

Using zeta potential for process control

Tittesworth WTW first began to control the clarification process using offline zeta potential measurements of the coagulant dosed water entering the flocculator in 2009. During ongoing trials zeta potential came close to both ends of the range defined as optimal for operation, highlighting opportunities for operational improvement in both instances.

Zeta potential values approaching the upper level of +3mV, showed that at this time too much positively charged coagulant was being added suggesting that chemical usage, and costs, could be reduced. Conversely drift towards the -10mV boundary indicated that coagulant levels were too low. In these circumstances increased dosing reduces the risk of an issue with water quality, a vital consideration.

Development of an on-line solution and encouraging results from early trials with Aurora Water in the US led Severn Trent to capitalise on their success with offline trials via an investment in continuous monitoring technology. An online system was installed in Tittesworth in 2014 along with a dedicated sampling loop to completely integrate measurement with process operation and minimise the risk of sampling errors.

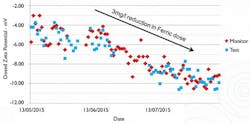

Online implementation has the advantage of reducing measurement variability and makes it practical to measure at far higher frequencies than could be accommodated with a manual analysis. However, lab-based zeta potential measurements were also run during the trial to compare the on and offline data.

The online solution delivered continuous measurements to the same precision and reliability as lab analyses with minimal manual input, amply demonstrating its effectiveness. As the trial progressed the operational team became more confident that the plant was under close control and consequently pushed towards the acceptable lower bound of zeta potential levels (-10mV) thereby realising a reduction of 3mg/L Fe in coagulant dosage levels. This represents a saving of approximately 20% in coagulant costs and was achieved without impacting plant performance.

Reviewing the benefits

A defining advantage of zeta potential measurement, relative to alternative monitoring techniques, is that the values produced show unambiguously how operation needs to be altered to safeguard water treatment performance.

This clarity has resulted in the online technology being enthusiastically received by plant operators. By producing a reliable indicator of process performance it has enabled the development of clear guidelines for plant control thereby delivering highly consistent operation. Crucially the measurements made are not impacted by water chemistry changes and no recalibration is required when water conditions change.

Informed decisions as to how to control the plant can now be made easily with remote support if necessary since it is straightforward to access to the relevant trend data through the SCADA system. This is a major gain for troubleshooting. Furthermore, alarms have been configured to alert operators to an issue instantaneously, allowing problems to be resolved before they impact downstream processes. This is particularly important with heightened and/or fluctuating NOM levels in the raw water. The ability to minimise the use of the coagulant means that levels of wastewater and sludge are reduced, compounding the savings from coagulant usage alone.

In summary, the trial has highlighted that online zeta potential analysis offers informative, high frequency measurement to support a fast and effective response to changes in water quality. Severn Trent has plans to install the Zetasizer WT at more upland water treatments works that deploy charge neutralization processes for NOM removal, to capitalise on these gains. Looking ahead, however, the technology offers even further potential for plant optimisation.

The guidelines for coagulant dosing are now so clear and concise that they could be relatively easily developed into algorithms for continuous automated control, with the online analyzer providing the data to drive such control. A fully automated, universally applicable system that works irrespective of water source for all charge neutralisation treatment plants is the long term goal. This would transform operating practice within the water industry enabling smarter, more efficient operation and the more robust control of risk.

Experience indicates that the technology is straight-forward to use, generates easy to understand data, and is suitable for all water sources or clarification systems, providing that NOM removal is being achieved via charge neutralisation. Tangible benefits include: reduced water quality risk; decreased coagulant usage; and improved operating efficiency. Furthermore, the technology supports the company’s long-term goal of establishing a secure platform for fully automated process control.

Emma Sharp is water treatment and quality lead - East and Joanne Claronino is technical lead at utility. Severn Trent. Alon Vaisman is product development manager, Adam Hall is process product manager and Kerry Hall is project engineer at Malvern Instruments.

References:

[1] E. Sharp et al. ‘Using online Zeta Potential measurements for full-scale coagulation control in drinking water treatment’, Proc. IWA Particle Separation: Advances in particle scence and separation 22-24th June 2016 Oslo, Norway

[2] E. Sharp et al. ‘Seasonal variations in natural organic matter and its impact on coagulation in water treatment’ Science of the Total Environment, Vol 363, Issues 1 - 3, June 2006 pp183 - 194.

[3] E. Sharp et al. ‘Impact of fractional character on the coagulation of NOM’ Colloids and Surfaces A Physicochem. Eng. Aspects, 286 (2006) 104-111

[4] E. Sharp et al. ‘A mechanistic approach to predict disinfection by-product precursor removal during conventional coagulation’, Proc. 12th International Gothenburg Symposium on Chemical Treatment of Water and Wastewater, 20th-23rd May, Ljubljana, Slovenia

[5] B. Fulbright et al. ‘How good is online Zeta potential measurement in water treatment?’, Water/Waste processing magazine, August 2014.

More Water & WasteWater International Archives Issue Articles