Contaminant Detection at Medical Facilities Aided by Test Kits

By Veliana Todorova and Jacques Naitychia

Use of Quench-Gone Aqueous bioluminescence test kits as a tool for implementing methodical risk analysis and surveillance programs in sanitary water and cooling towers

Assessment of microbiological risks in the various water networks (industrial water, cooling tower water, sanitary water) requires measurement of bacterial contamination. Water network operators need tools allowing better reactivity in case of sanitary problem in the installations due to microbial proliferation. Such tools are urgently required for installations where the progressive decrease in water quality is particularly critical, such as hospitals and health care institutions.

Monitoring of sanitary risks linked to hydraulics requires implementation of a program for continuous improvement of water quality. In France, this program is based on two steps: 1) evaluation, and 2) management. The evaluation of sanitary risks should allow their quantification according to the danger linked to exposure to the critical parameter. Methods such as HACCP (Hazard Analysis Critical Control Points) are used for the identification of critical control points associated with critical microbiological parameters. Risk management is based on the definition and implementation of technical and organizational means for efficient risk control.

The follow-up of the defined risk monitoring program requires periodic sampling of water for surveillance of its microbiological quality at critical control points. Standard methods used in hospital hygiene monitoring are based on classical microbiology and require from 24-72 hours for results (and up to 10 days in case of Legionella detection). This delay of results may be critical when fast corrective actions need to be deployed to avoid rapid drift of the quality of water leading to infection of high risk patients.

Quench-Gone Aqueous (QGA) test kits developed by LuminUltra Technologies Ltd., of Fredericton, New Brunswick, Canada, and commercialized in Europe, the Mid-East and Africa by Aqua-tools.com are a new generation of bioluminescence method for quantification of active biomass present in water samples. Through measurement of only intracellular ATP (adenosine triphosphate), a molecule which is the main energy carrier of the cell, total viable microorganisms in the water sample are quantified in 10 minutes.

The principle of ATP measurement is based on a bioluminescence technique, in which one photon of light is produced in the enzymatic reaction between Luciferase and an ATP molecule. Intensity of light is measured with a luminometer. The quantity of produced light is directly proportional to the active biomass present in the sample. This reaction is linear over many orders of magnitude, allowing the assay to be used in very clean applications such as drinking water and also in dirty applications such as wastewater.

These test kits provide a rapid means for identification of critical control points within the installation and an ability to quickly establish and assess effectiveness of corrective treatments. This new tool allows fast follow-up and instantaneous control to fix on one hand, effective dosing and the efficiency of a treatment at an installation and, on the other, to be successful in disinfecting any water network. Performance of the method was demonstrated during resolution of a persistent problem linked to Pseudomonas aeruginosa proliferation in a French hospital. The fast localization of the contamination lead to immediate implementation of corrective actions and verification of their efficiency.

Cold Water Solution

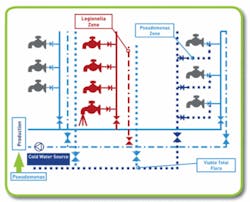

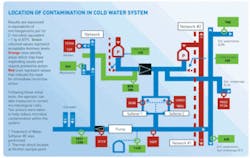

Over the course of several months, the French hospital observed a persistent contamination by P. aeruginosa in the cold water circuit supplying the endoscope room. The hospital also had encountered problems with aerobic flora proliferation in cold water and Legionella contamination in hot sanitary water. A system survey using ATP measurements was done at different points throughout the system to determine if contamination was localized or if the entire system had excessive amounts of bacteria. The preference would be to pinpoint critical junctures and take localized corrective actions rather than undertaking a disinfection of the global network. A global disinfection approach would be more difficult considering the consistent need of water throughout the hospital for equipment and patients, to say nothing of the elevated cost. Still, without completing a survey this approach would be the only one available.

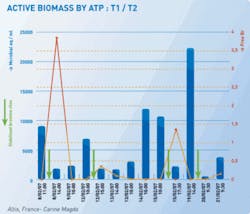

A sampling plan for the cold and hot water distribution lines was established as follows: cold water inlet, auxiliary equipment (including pressure reducers and water softeners), main inlet pipes supplying both distribution networks (#1 and #2) and finally the local inlet pipes supplying the endoscope rooms. A first series of ATP measurement analysis, made in one half day, was performed using the new ATP kit. The results (see Figure 2) clearly show that the water softener #2 had a major buildup of biomass, which appeared to be responsible for the contamination of the water line supplying the endoscope room. This piping is directly connected behind this softener. In addition, the reference point of the kitchen is qualified as contaminated. This second contamination seemed to be localized only at the endpoint of the tap, as sampling at the upfront critical point (washroom) show correct results.

Localized chemical disinfection of the softener #2 and the kitchen tap was performed as a corrective action and was executed at the same day. Following the corrective actions, measurements were repeated and are shown as the second number at each point in Figure 2. After disinfection of the softener, the results returned to an acceptable level. The piping supplying the endoscope room developed a biofilm resistant to a chemical decontamination. A softener had to be installed here to liberate the network.

The two analyses on the return sealing taps of hot sanitary water clearly show the disinfection action (through reverse current circulation of chlorinated water at 60°C) is efficient in removal of Legionella. It should be noted that the colour of the water coming from the stagnant sealing taps (the source of the contamination) was that of coffee.

Field Trial Outcome

Using two sets of measurements before and after corrective actions, ATP measurements employin the new bioluminescence kit facilitate quick identification of localized contamination, decision on corrective action, and immediate follow-up of the results without wasting time. After this step, specific bacterial analyses are established to verify regulatory compliance. Finally, this case study demonstrates the utility of a new generation ATP method as a tool to assess and follow-up total biomass evolution in a water network on a proactive basis.

The fast delivery of results (10 min) makes early detection of biomass proliferation, implementation of corrective actions and theirimmediate verification possible. Routine total biomass measurements provide an effective tool for water system protection and allow preventing of sanitary problems at the early steps.

Following this field trial, a methodical risk analysis scheme was developed to be implemented in sanitary water networks in hospitals and health-care establishments. The scheme is divided in five separate steps leading to a more thorough knowledge of the sanitary water network and defining critical control points and their classification. The aim of this methodical risk analysis, based on the use of QGA ATP kits, is to be able to more quickly detect any drift in water quality and, thus, offer more efficient management of sanitary risks.

Methodical Risk Analysis

The methodical risk analysis based on using the new generation of ATP bioluminescence test kit technology consists in the following steps:

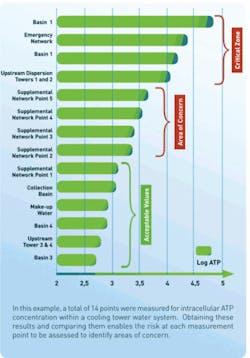

- Define the Control Points using Methodical Risk Analysis Measuring the planktonic intracellular ATP in a variety of locations throughout a given water system allows an assessment of the level of risk through the system. Depending on the size and complexity of the system, it’s common to identify up to 10 critical control points for routine monitoring.

- Identify Critical Points and Set up a Routine Test Program Moving forward, a routine testing schedule can be established for the identified critical control points. Major critical points can be followed-up at higher rate than others to gain improved control, which is an effective approach given the low cost associated with this test and that a biomass growth rate of more than 0.3 log (i.e., growth of 100%) has to be considered as significant and has to be explained or, at least, controlled in the early stages of detection for effective control.

- Install Preventive and/or Corrective Actions Actions to maintain effective control decided and driven by the Methodical Risk Analysis Committee are meant to reduce installation risks. These actions can most often be followed-up by ATP measurement. For example, a chemical cleaning action implemented to reduce the biomass fixed on the surface of an installation will reduce the fixed (sessile) biomass, but will temporarily increase the planktonic biomass. Kinetics of these two actions should be assessed to optimize cleaning by purging the lines or to inject biocide to neutralize the dropped bacteria. Using ATP measurements to assess these effects is a perfect rapid and direct solution to optimize this approach.

- Survey a Balanced and Stable Installation According to French AFNOR standard guidelines (NF T 90-471), a specific analysis has to be done every month in a cooling tower network. Ecosystem excesses sometimes appear very quickly, however, and the situation will be all the more difficult to reverse if not detected as it occurs. Therefore, early detection of any starting change will be an advantage, and a more frequent measure of total biomass using ATP monitoring perfectly fits to this approach.

- Perform Audit of Locations Example: Using ATP measurements to define the control points using the Methodical Risk Analysis and compensating actions.

Conclusion

ATP measurements are the best indicator for operational monitoring and tracking corrective and preventive actions of risks associated with active microorganisms in any water application. From source water to drinking water and even industrial process water, measurement of ATP is the first line of defence as part of a strategy for microbiological risk analysis and controls (according to the philosophy of AMDEC, HACCP, or similar methods). The new generation of ATP tests, Quench-Gone Aqueous kits, can be used as a daily surveillance tool for active biomass concentration in any water system. Measuring total biomass on a frequent basis will provide an early warning of impending issues, which will help operators to supervise the critical points of the installation in order to be proactive as soon as an evolution in the biomass quantity occurs. Following this first line of defence, additional analyses to identify the growth rate or species of the microorganisms can be used to provide more information.

Author’s Notes:

Veliana Todorova is business development manager of Aqua-tools.com, of Aulnay-Sur-Mauldre, France. It specializes in marketing and sales in Europe and Middle East/North Africa of Luminultra ATP kits for all water applications: sanitary water, industrial water, purified water, cooling tower water, waste water in Europe. Contact: + 33 1 30 95 79 50, veliana. [email protected] or www.aqua-tools.com

Jacques Naitychia works for Isagua Conseil, of Charenton le Pont, France, a company specialized in trainings, consultancy and expertise on water installations. He is the former manager of water networks in AP-HP (Welfare services - Hospitals of Paris). This article is based on a November 2007 paper presented at Pollutec Horizons in Paris.