Controlling Disinfectant Residuals

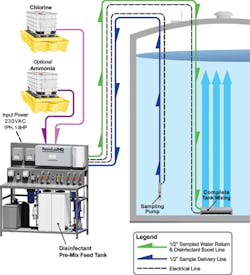

Medora Corporation’s ResidualHQ© Automated Disinfectant Control is a continuous residual monitoring and disinfectant delivery platform for both chlorine and chloramine applications. Control your disinfectant residuals with intelligent, data-driven decisions for better water quality. The proven technology helps maximize performance, minimize moving parts and simplify overall operation and maintenance without chemical transfer pumps or chemical metering pumps.

Monitor

The ResidualHQ© combines industry-leading active mixing in the tank to provide dependable and representative sampling with constant system circulation for continuous real-time monitoring of the disinfectant residual. This constant circulation combined with targeted use of soft water during boosting cycles keeps a majority of chemically contacted components flushed and clean. The disinfectant residual sensors are reagentless and all system data are logged, displayed and SCADA accessible

Respond

The ResidualHQ© tracks and trends disinfectant residual trends over time and incorporates highly adjustable and configurable parameters such as action thresholds, response types (chlorine vs. chloramine), feed concentrations, and feed ratios. This gives you the ability to set your response how you want, when you want.

The ResidualHQ© also utilizes an industry-first Disinfectant Proportioning “Pre-Mix” Tank to safely prepare initial disinfectant, whether chlorine or chloramine, to desired strength parameters. From there, the initial disinfectant is delivered directly into the inlet-side of a Medora Corporation active potable tank mixer where it is further mixed and diluted. Finally, it is delivered and thoroughly mixed into the entirety of the tank volume.

The ResidualHQ© provides continuous real-time monitoring of disinfectant residual.

The result is a rapid, properly ratioed, well-mixed, and safe disinfectant delivery and distribution.

Verify

Once disinfectant distribution takes place, the next step is to verify the outcome with levels of redundancy to ensure a proper end result. The ResidualHQ© “learns” based on previous experiences and results to maintain constant residual balance. Once the desired outcome is achieved, the ResidualHQ© reverts back to Monitoring Status until the next response is needed.

The ResidualHQ© operates up to three months between general maintenance checks and calibration. Maintenance checks are simple and include general system inspection, level checks for softener salt and disinfectant bulk tanks, and disinfectant monitor calibration that only takes minutes (any maintenance can be done with everyday hand tools if ever needed).

The ResidualHQ© utilizes a Disinfectant Proportioning “Pre-Mix” Tank to safely prepare initial disinfectant to desired strength parameters.

Design

The ResidualHQ© is engineered into a convenient and user-friendly work station that is safe, reliable, and easy to use. It comes with tiered access security and can be controlled onsite or remotely. Sized to accommodate small tanks to large mega-reservoirs; a mobile trailer or in-building installations are available.

Start your project evaluation

Most ResidualHQ projects start with a pre-evaluation questionnaire to get as many details about your system and your treatment challenges as possible. Visit Medoraco.com/ResidualHQ to see educational videos and download the form. WW

Medora is exhibiting at ACE19, booth 3036. Learn more at www.medoraco.com.

Circle No. 278 on Reader Service Card