Preventing Water Theft, Meter Tampering, and Magnetic Field Interference

In Part 1 of this three-part series, authors Adam Kozlowski and Janusz Dubicki explain magnetic field interference and its adverse effects upon the measuring accuracy of commercial and residential water meters. By understanding the impacts of a magnetic field and the meter components that might be susceptible to magnetic inference, meter manufactures can implement design improvements intended to sustain the accuracy in these devices. Our authors launch this topic on water meter design and measuring capacity improvements in the introductory segment below and continue to explore these topics throughout the continuations that follow.

Crime Stopper (Part 1) By Adam Kozlowski and

Janusz Dubicki

The fight against water theft with the use of strong magnetic field

How do you protect your meter network from losing its measuring capability? One option to improve and protect measure devices like dry-dial water meters is to use passive magnetic field indicators to detect the action of a strong magnetic field primarily coming from neodymium magnets. These indicators are especially useful for water meters already in use in networks (external installation), but in the case of new water meters, the passive magnetic field indicators can, by design, be installed also inside the device. The indicators are also used to detect a strong magnetic field action on other vulnerable measuring devices, like watt-hour meters and gas meters.

Introduction

The uses of neodymium magnets or a magnetic field, created also by electromagnetic devices, can have a negative influence on the correct functioning of measuring devices through reversible or irreversible changes of their measuring characteristics. For example, many electromechanical induction and electronic watt-hour meters lower their indications of electric energy consumption, and low-voltage current transformers decrease the currents in their secondary windings (Hazardous influence of rare-earth magnets on low-voltage current transformer as the evidence of EMC compatibility lack 2006). Dry dial water meters and many gas meters completely lose their capability of measuring the medium used in spite of its flow. The described situations are evidence of the lack of electromagnetic compatibility of measuring devices (Directions of protection of watt-hour meters from influence of external magnetic fields 2005).

Information about influencing the measuring characteristics of devices to reduce their indications is becoming more easily accessible from many sources: articles (Source: www.ednasia.com/print.asp?articleId=23996), Internet Web sites, and discussion forums (Slowing down electric meter 2008). Additionally, the great accessibility of neodymium magnets and the continuous decrease in their prices (because of cheap mass-production in China) has had an influence on the propagation of the phenomenon of illegal media consumption with the use of these magnets. This phenomenon is well known in Asia and Europe, and also appears in the US (“To Catch a Thief”).

Basic Information About Rare-Earth Magnets

Development of the group of magnets based on rare-earth elements dates from the 1980s, when the Japanese Sumitomo Company obtained patent protection of the metallic compounds of ferromagnetic cobalt (Co), samarium (Sm), and also ferromagnetic iron (Fe) and neodymium (Nd) with boron (B) (Source: www.sei.co.jp ).

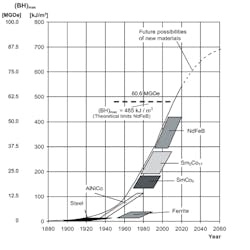

Considering the fact that samarium and neodymium belong to elements, which very rarely occur in nature, they are called rare-earth elements, and magnets with these elements are named rare-earth magnets. Magnets of the NdFeB type are characterized by extremely high-energy density values: 37.7–50.3 MGOe (300–400 kJ/m3) (Figure 1).

Dry Dial Water Meters

The most widespread construction of water meters is the dry dial meter. It is characterized by the separation of the counter gear and counter from flowing water, which forces the turbine to work. A magnetic clutch is used to transfer the drive from the turbine placed in the “wet” chamber of the meter to the counter, placed in the “dry” chamber.

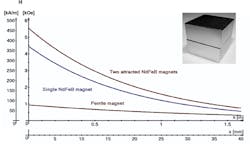

For instance, according to the European standard EN 14154 (Water meters–Part 3: Test methods and equipment 2005) in force, water meters should be resistant to an external magnetic field with a field strength up to 1.26 kOe (100 kA/m). A ferrite magnet with the energy of 6.28 MGOe (50 kJ/m3) creates such a value (Figure 2).

However, water meters meeting the requirement of the standard are not resistant to the action of neodymium magnets, which create magnetic field strengths over four times greater than ferrite magnets (Figure 2) [Directions of protection of watt-hour meters from influence of external magnetic fields 2005]. A neodymium magnet influences the magnetic clutch of the dry dial water meter, causing a complete stop of its measurement despite flowing water (Figure 3).

However, after removing the magnet from the dry dial water meter, its indication returns to its correct measuring class. The interference process is fully reversible-–the magnet does not damage the water meter.

Construction Changes in Measuring Devices

The problem of the magnetic non-resistance of many measuring devices, including dry dial water meters, has forced on their producers construction changes in these devices, e.g., replacement of elements with non-ferromagnetic ones, increasing the distance between the problematic subassemblies and the casings of the measuring devices, as well as internal or external magnetic screens. All these activities are connected with eliminating the negative influence of a strong magnetic field or its limitation. In fact, all these activities, like magnetic shielding, raise the threshold of magnetic resistance of measuring devices, but they will never be completely resistant to a stronger magnetic field, e.g., created by attracted neodymium magnets (Figure 2).

Moreover, all these changes can be done only at the design and production stage, but the problem concerns, first of all, many millions of already-installed measuring devices in networks. In this case, there is no possibility to change the design of those devices.

In the case of already-installed measuring devices, the simple solution seems to be not to eliminate the negative influence of strong magnetic fields, but their permanent detection. Nowadays there are some devices, which can detect if a neodymium magnet was used. They work on the basis of the Hall effect, magnetoresistance effect, or change the domain structure of magnetic material (European Community Design No. 000485487 2006).