World Water Works Announces Ideal Pre-Fab Pre-Engineered Skid-Mounted Systems

State of the art “plug-and-play” technology accelerates schedules and reduces costs

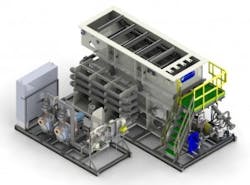

Oklahoma City, Okla. – June 22, 2015 – World Water Works, a leading designer and manufacturer of wastewater treatment solutions, announces the launch of its new Ideal Pre-Fab™ product line. The sustainable design incorporates core IDEAL™ products into pre-engineered skid-mounted systems, offering customers a “plug-and-play” option that greatly reduces onsite work. Ideal Pre-Fab arrives fully assembled, pre-wired and pre-plumbed, with little installation required, and is available for the Ideal DAF™ (Dissolved Air Flotation), Ideal MBBR™ (Moving Bed Biofilm Reactor) and the Ideal S-Select® bulking sludge management technology.

The unique wastewater treatment technology with pre-calibrated instrumentation, chemical feed systems and control systems, minimizes concerns about safety, quality and schedule optimization while dramatically reducing overall project costs and delivery times.

State of the art “plug-and-play” technology accelerates schedules and reduces costsOklahoma City, Okla. – June 22, 2015 – World Water Works, a leading designer and manufacturer of wastewater treatment solutions, announces the launch of its new Ideal Pre-Fab™ product line. The sustainable design incorporates core IDEAL™ products into pre-engineered skid-mounted systems, offering customers a “plug-and-play” option that greatly reduces onsite work. Ideal Pre-Fab arrives fully assembled, pre-wired and pre-plumbed, with little installation required, and is available for the Ideal DAF™ (Dissolved Air Flotation), Ideal MBBR™ (Moving Bed Biofilm Reactor) and the Ideal S-Select® bulking sludge management technology. The unique wastewater treatment technology with pre-calibrated instrumentation, chemical feed systems and control systems, minimizes concerns about safety, quality and schedule optimization while dramatically reducing overall project costs and delivery times. [text_ad] “The entire fulfillment process is simplified,” said Kyle Booth, COO for World Water Works. “We essentially adapted the housing industry’s successful modular pre-fabrication concept to the wastewater market. Our first customer to receive the Ideal Pre-Fab system, a poultry plant in Pennsylvania, started up within just three days of delivery and has been running consistently ever since.”World Water Works’ 3D design and modular construction process allows a controlled environment that optimizes the use of materials, time and energy, lowering construction site waste by as much as 15 percent. In addition, project schedules are reduced more than four to eight weeks due to the accelerated and efficient engineering of the Ideal Pre-Fab technology and the reduction of onsite construction time, which in the end achieves a higher degree of product predictability and increased ROI.

Booth adds, “The overall result of using World Water Works’ Ideal Pre-Fab system is a sustainable, state of the art project that is delivered ahead of schedule, and assures lowest life cycle costs for our customers. It’s a groundbreaking technology for the water and wastewater industry and we are excited to be on the forefront.”

About World Water Works

World Water Works is a leading manufacturer of specialized process and wastewater treatment technologies. With a focus on cost effective performance, flexibility, and durability, the company partners with clients to identify and create the most appropriate water treatment solutions. Since its founding in 1998, the company’s technology has cleaned more than 13 trillion gallons of water, facilitated the reuse of more than 2 trillion gallons and recovered millions of pounds of resources. For more information visit WorldWaterWorks.com.